White light microscopic interferometry system and method capable of acquiring spectral information

A technology of spectral information and microscopic interference, which is applied in the direction of color/spectral characteristic measurement, measuring device, phase influence characteristic measurement, etc., can solve the problem that the spectral information and surface microscopic shape of the measured sample cannot be obtained at the same time, and achieve Save experimental steps and time, the structural design is simple and ingenious, and the effect is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

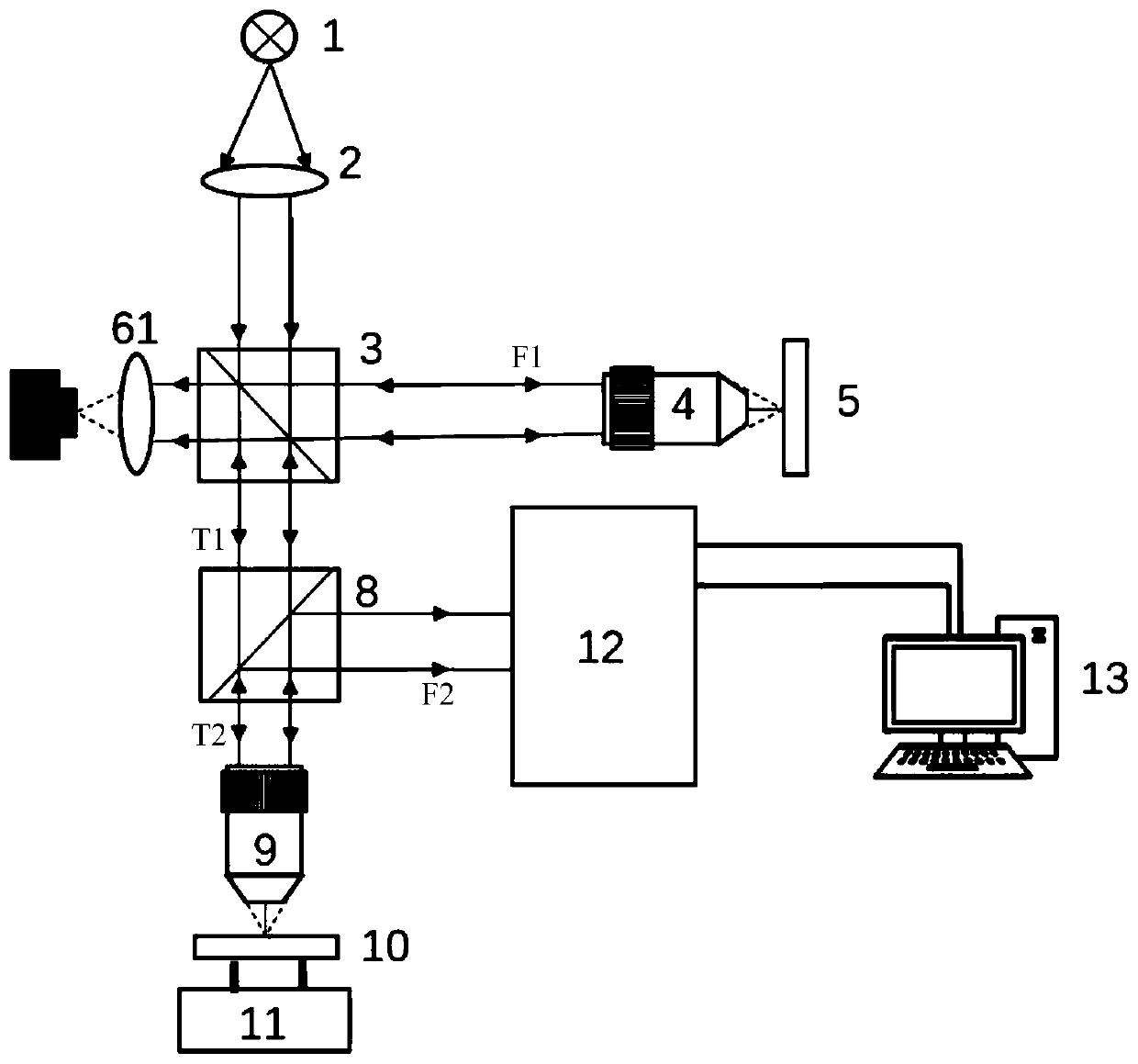

[0046] A white light micro-interferometry system that can obtain spectral information, such as figure 1 As shown, it includes a wide-spectrum light source 1, a first beam splitter 3, a first microscopic objective lens 4, a second beam splitter 8, a second microscopic objective lens 9, a first CCD detector 7 and a spectral detection module 12;

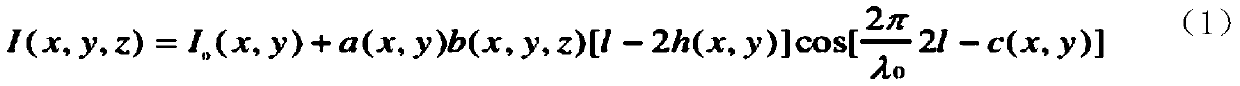

[0047] The wide-spectrum light source 1 is collimated by a collimator lens 2 into parallel light and then vertically incident on the first beam splitter 3, where it is divided into transmitted light T1 and reflected light F1, and the reflected light F1 is focused on the reference plane by the first microscopic objective lens 4 5, the reference light is obtained after being reflected by the reference plane 5, and the reference light is irradiated on the first beam splitter 3 through the first microscope objective lens 4 along the optical axis direction, and the transmitted light T1 is divided into the transmitted light by the second beam ...

Embodiment 2

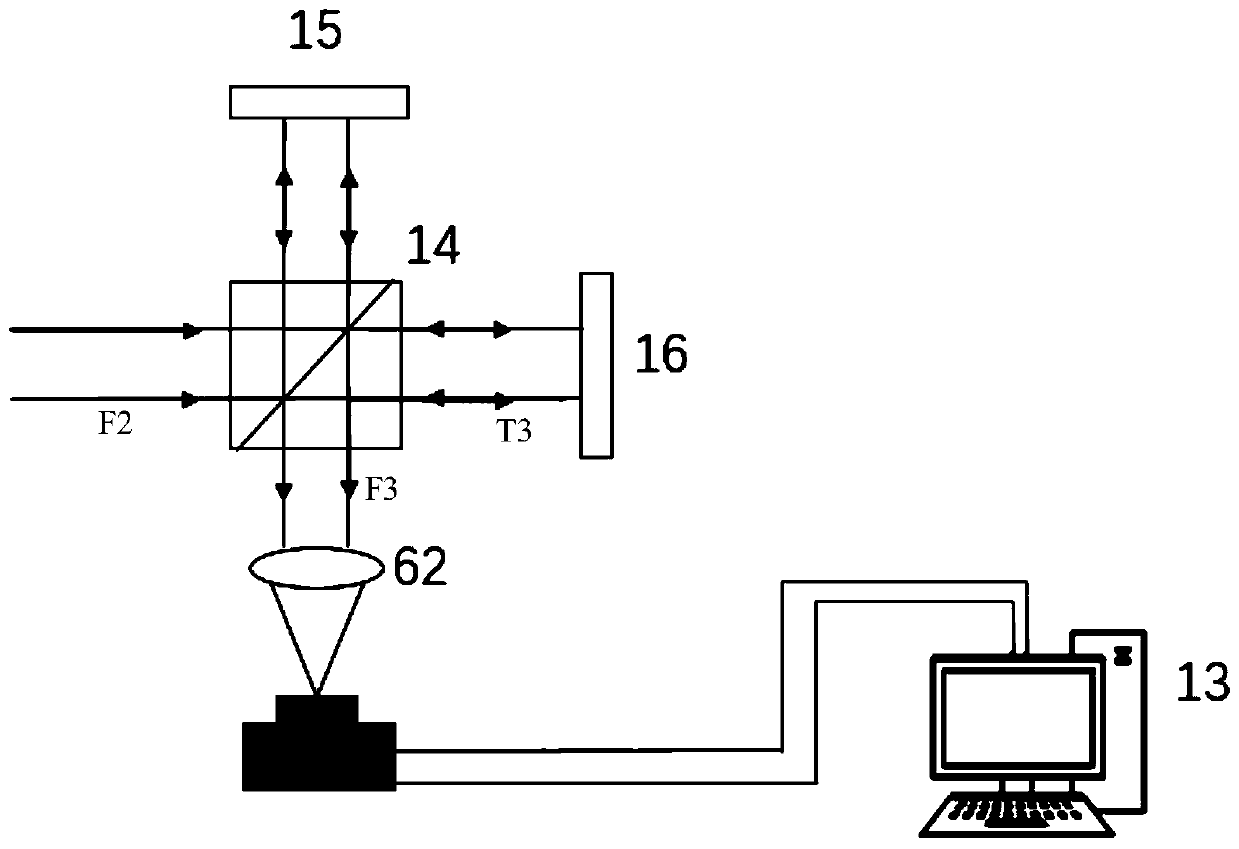

[0050] A white light microscopic interferometry system capable of obtaining spectral information, its structure is as shown in Embodiment 1, the difference is that the spectral detection module 12 includes a third beam splitter 14, a moving mirror 15, a fixed mirror 16, a second CCD detector 17 and PC terminal 13;

[0051] The reflected light F2 is divided into the transmitted light T3 and the reflected light F3 through the third beam splitter 14, the transmitted light T3 is reflected by the fixed mirror 16, the reflected light F3 is reflected by the moving mirror 15, and the two beams of light interfere on the third beam splitter 14 The generated interference light is received by the second CCD detector 17 through the second focusing lens 62 , and then processed and recorded by the PC terminal 13 . The second CCD detector 17 in the spectral detection module 12 is connected to the PC terminal 13, and the obtained interference pattern detected by the second CCD detector 17 firs...

Embodiment 3

[0053] A white light microscopic interferometry system that can obtain spectral information, its structure is as shown in Embodiment 1, the difference is that the reflection surface of the second beam splitter 8 and the direction of the test light reflected back from the plane 10 to be measured At an included angle of 45° clockwise, the test light containing the sample plane information is introduced into the spectrum measurement module to detect the spectrum signal;

[0054] The reflective surfaces of the first beam splitter 3 and the third beam splitter 14 form an included angle of 45° counterclockwise with the direction of the respective incident light, and divide the incident light beam into transmitted light and reflected light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com