Tunnel excavation unloading simulation testing device and testing method

A simulation test, excavation and unloading technology, applied in the direction of teaching models, educational tools, instruments, etc., can solve the disturbance of surrounding rock, can not reflect the specific relationship between the deformation and failure of the roadway surrounding rock and excavation unloading parameters, and cannot measure the surrounding rock Rock-related mechanical parameters and other issues, to achieve the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

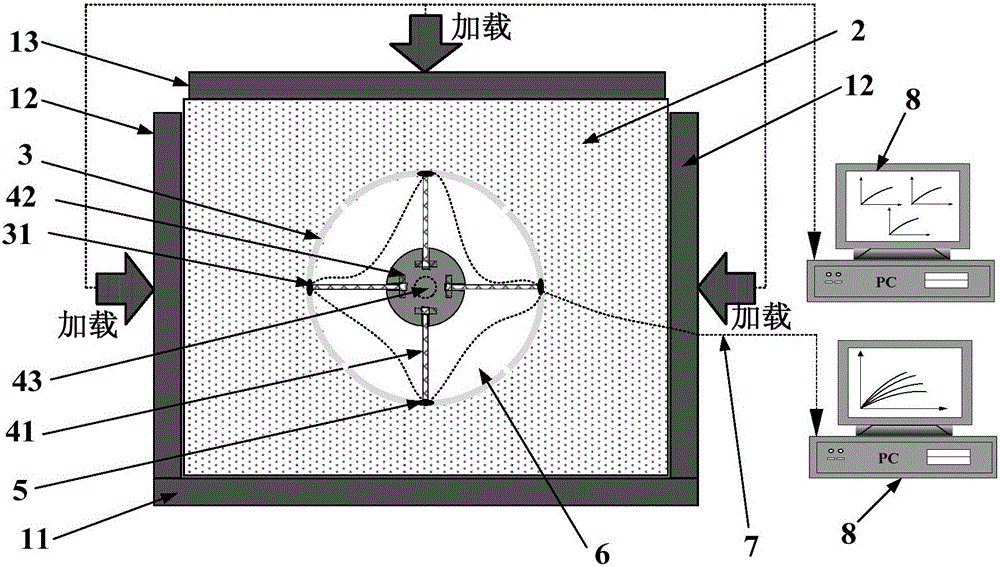

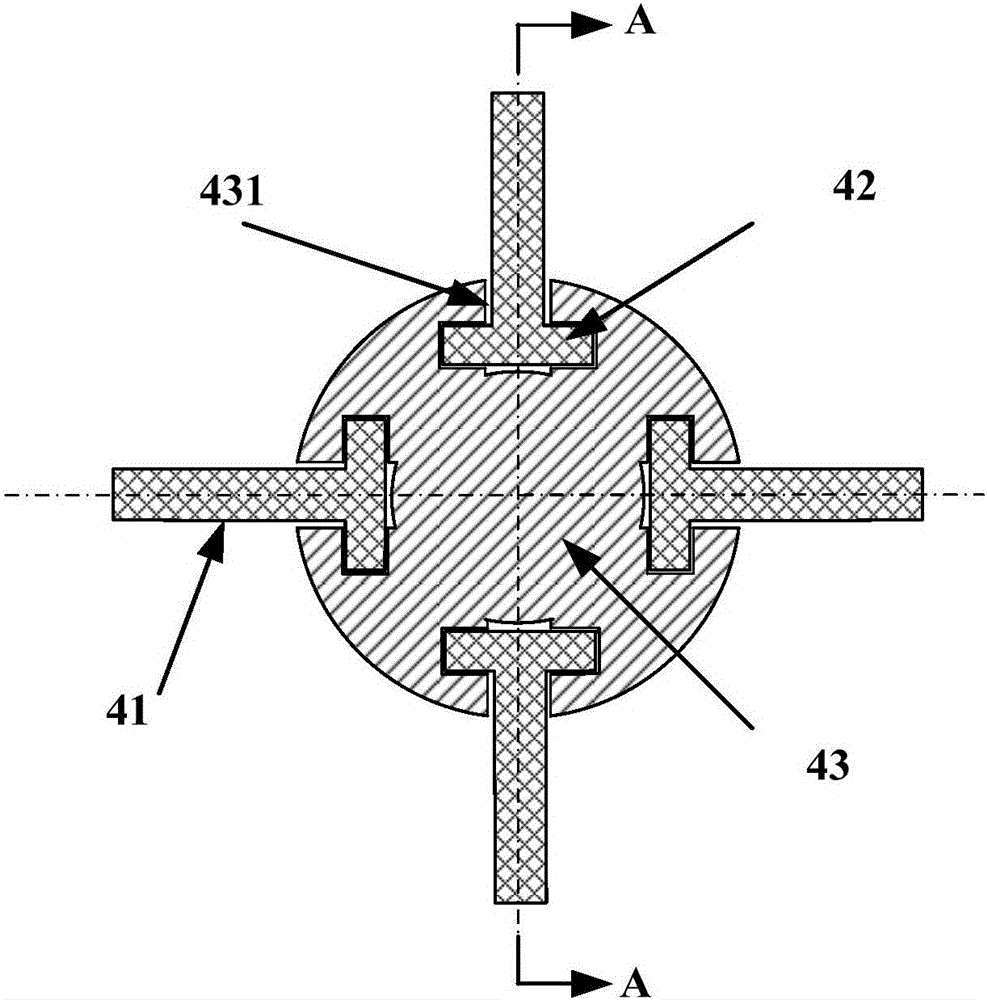

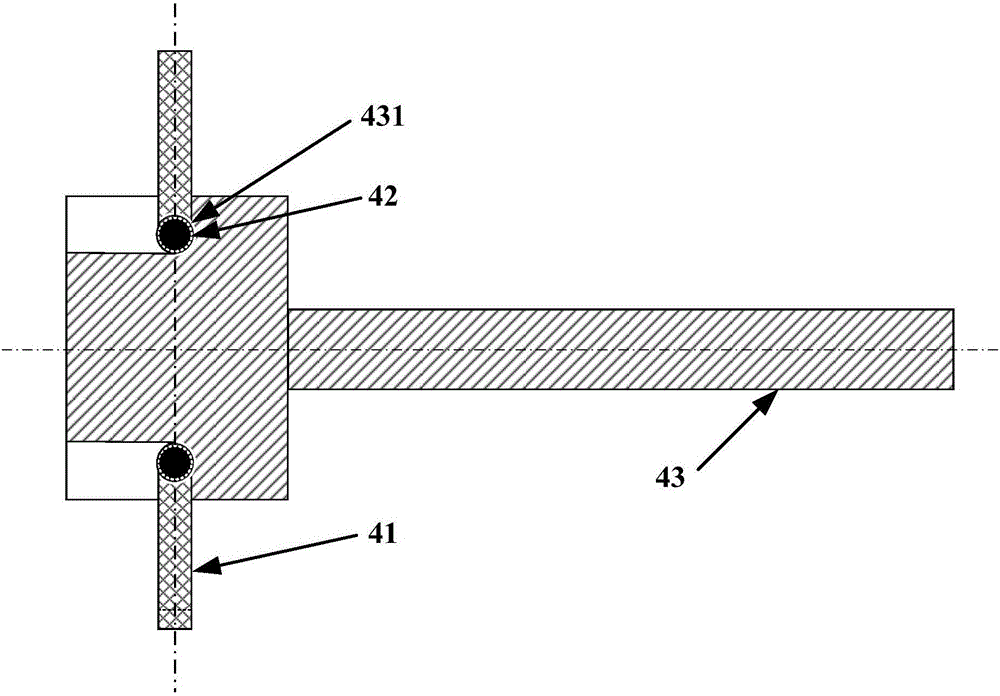

[0031] Such as Figure 1 to Figure 4 As shown, this embodiment provides a roadway excavation and unloading simulation test device. The lower bearing plate 11, the side bearing plate 12 and the upper bearing plate 13 made of solid steel plates jointly wrap the sample 2, and the sample 2 There is a cylindrical prefabricated roadway 6 inside, and a fixed plate 3 is laid along the outer surface of the prefabricated roadway 6. The shape of the fixed plate 3 is an arc that fits the outer surface of the cylindrical prefabricated roadway 6. shape. Of course, the shape profile of the prefabricated tunnel 6 can also be other shapes, for example, the cross section of the prefabricated tunnel 6 is a rectangular cylindrical shape, and at this time, the fixing plate is a planar structure conforming to the outer surface of the prefabricated tunnel 6 . Designing the prefabricated roadway 6 as a cylinder is convenient for opening the prefabricated roadway 6 for the test, and also facilitates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com