Installing structure of automobile top cover decoration strip

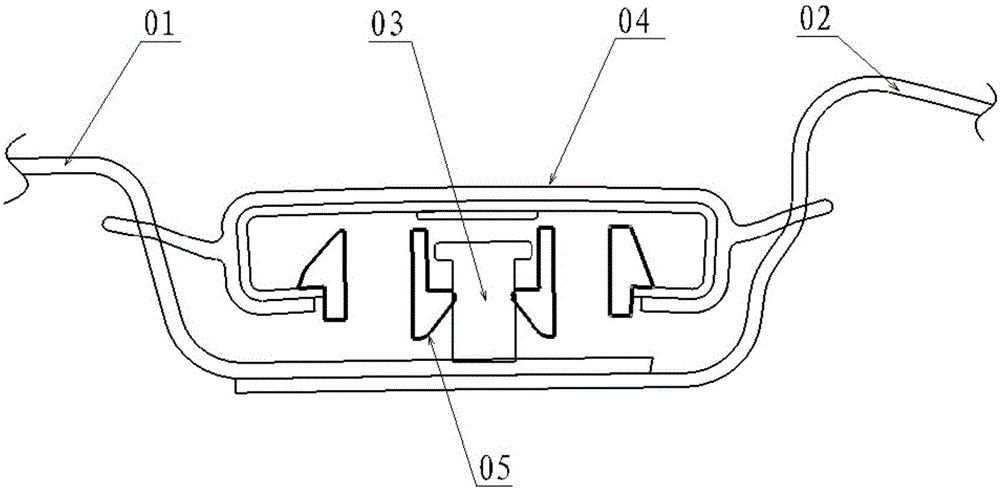

A technology for installation structures and car roofs, which is applied to vehicle parts, transportation and packaging, etc. It can solve problems such as unstable installation, difficulty in ensuring, and poor sealing, and achieve the requirements of ensuring flexibility and sealing, firm installation and Reliable, fast assembly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

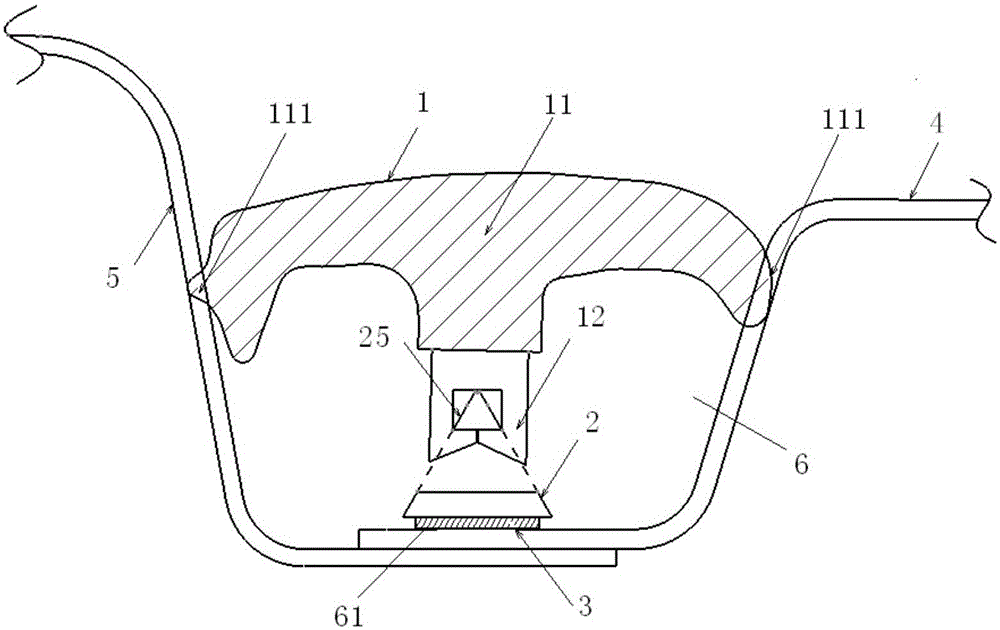

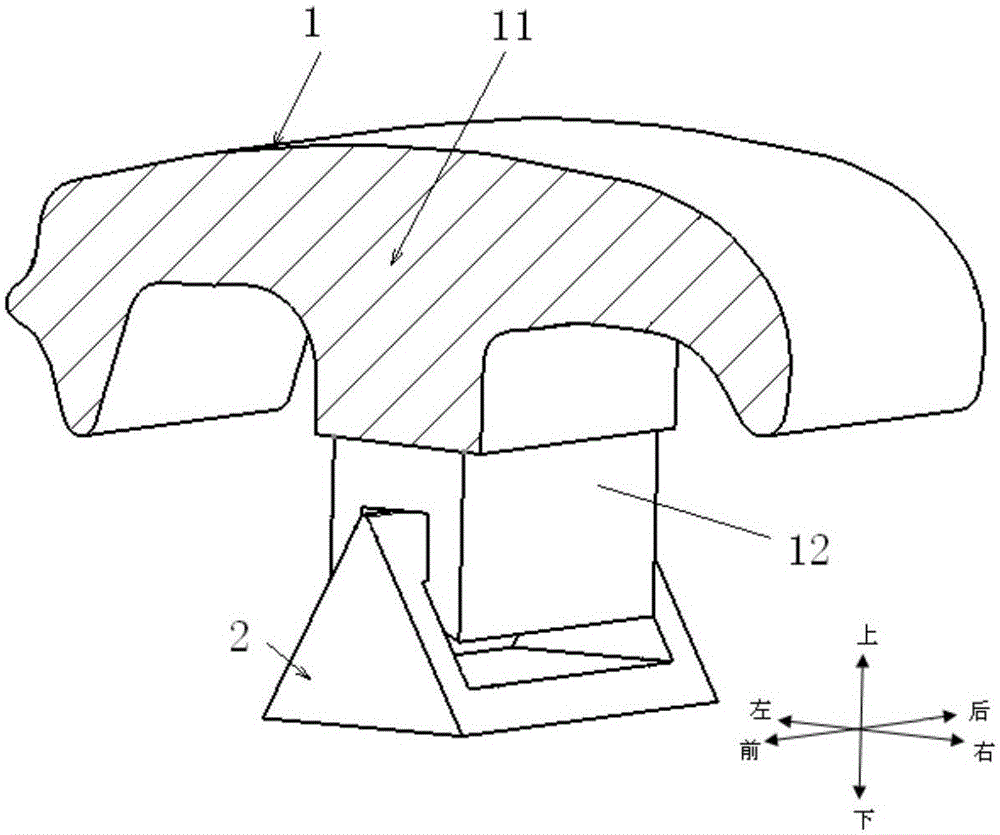

[0023] Such as Figure 2 to Figure 5 The installation structure of the car roof trim strip shown includes a roof trim strip 1, a groove 6 formed by overlapping the side wall 5 and the roof cover 4, and a clip bonded on the bottom wall of the groove 6. Seat 2. The top cover decorative strip 1 includes a decorative strip body 11, and an elastic buckle body 12 is connected to the middle part below the decorative strip body 11. Lips 111 are respectively provided on the left and right sides of the groove 6, and the two lips 111 are interference fit with the two side walls of the groove 6 respectively.

[0024] Such as Figure 5 Shown, described deck 2 is hollow triangular body shape, comprises upper crossbeam 25, lower floor 23, front connecting block 24 and rear connecting block 21, and the front and rear ends of described upper crossbeam 25 are connected with the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com