Vacuum pipeline length compensation device

A technology of length compensation and vacuum pipelines, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc. It can solve the problems of construction progress and construction quality, pipeline size deviation, and two sections of pipelines that cannot be connected normally. Achieve the effects of simple structure, guaranteed sealing requirements, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

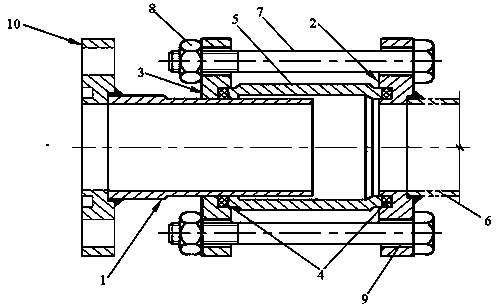

[0017] The vacuum pipeline length compensation device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

[0018] Such as figure 1 As shown, a vacuum pipeline length compensation device includes a pipe joint 1, a concave flange 2 and a flange 3 for a compensator, and the opposite side end faces of the concave flange 2 and the flange 3 for a compensator are formed with The annular groove of the hole, the other side of the concave flange 2 is connected to the pipe 6, and the concave flange 2 and the compensator flange 3 are provided with a gasket 4 in the annular groove; one end of the pipe joint 1 is welded with a flange 10. The other end extends into the central through hole of the flange 3 for the compensator; the sleeve 5 is in the shape of a hollow cylinder, and one end of the sleeve 5 is placed outside the pipe joint 1 and inserted into the annular groove of the flange 3 for the compensator. The other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com