Magnetorheological material-based high-efficiency rotating speed control device

A speed control, magnetorheological technology, applied in control systems, control generators, electrical components, etc., can solve the problems of electronic components breakdown, large output voltage, damage to key parts, etc., to increase the magnetic field line. density, increase the magnitude of the magnetic field, increase the effect of direct action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

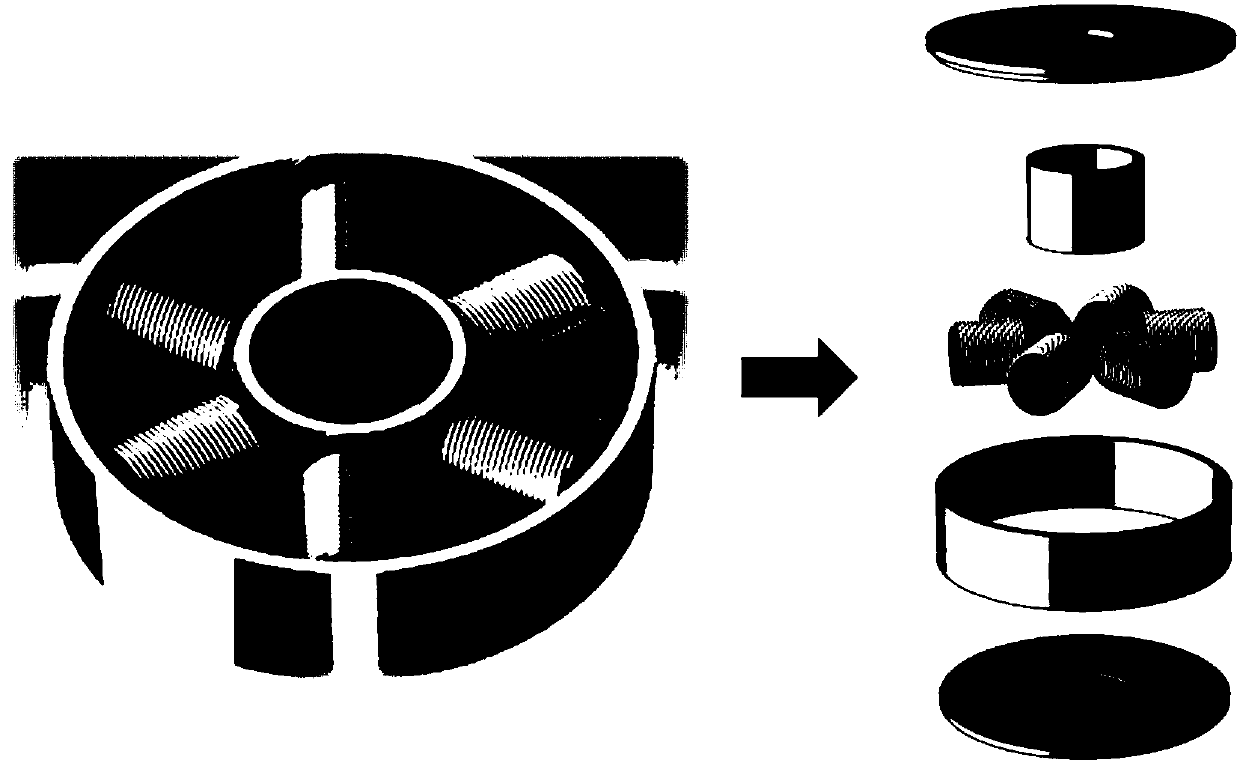

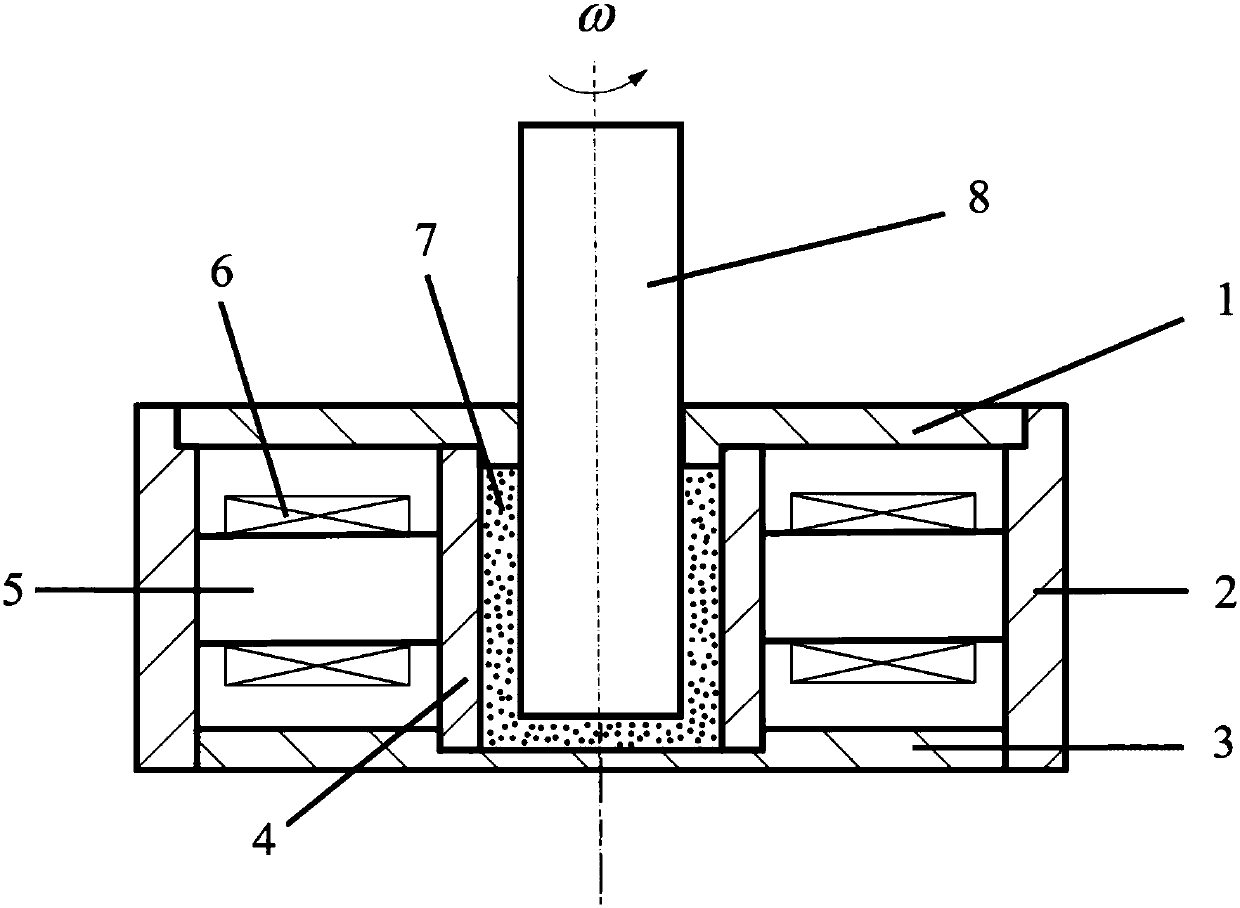

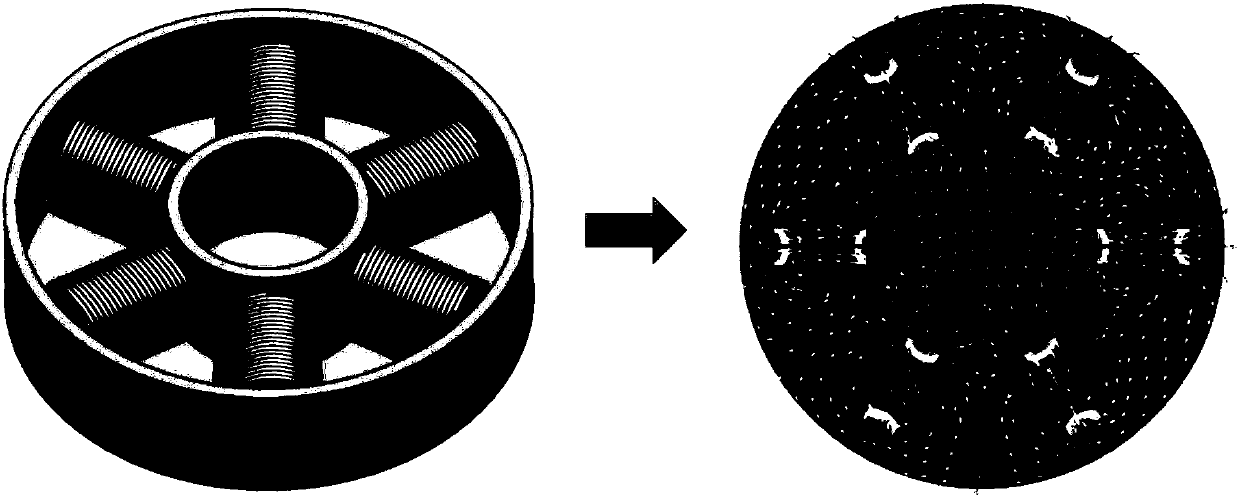

[0028]A magnetorheological material-based high-efficiency speed control device disclosed in this embodiment includes an upper cover 1 , an inner cylinder 4 , a casing 2 , a bottom 3 , an excitation coil 6 , a magnetic core 5 and a magnetorheological material 7 . The upper cover 1, the inner cylinder 4, the outer shell 2 and the bottom 3 form a base. Peripherals include turbine generators. The speed control device is fixedly connected with the bottom 3 parts of the turbine generator, and the center of the upper cover 1 of the base of the speed control device is provided with a circular hole with a diameter 2mm larger than the diameter of the turbine generator shaft 8, and the turbine generator shaft 8 protrudes The casing part of the turbine generator passes through the central hole of the upper cover 1 of the speed control device, and the turbine generator shaft 8 is suspended in the inner cylinder 4, and the turbine generator shaft 8 and the inner cylinder 4 maintain the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com