Grinding method for ring-shaped part

A grinding method and ring-shaped technology, applied in the field of machining, can solve the problems of inconsistent height of parts, out of tolerance parts, and poor sealing effect of parts, so as to ensure consistency, guarantee clearance requirements and sealing requirements, guarantee Effects of Accuracy and Adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

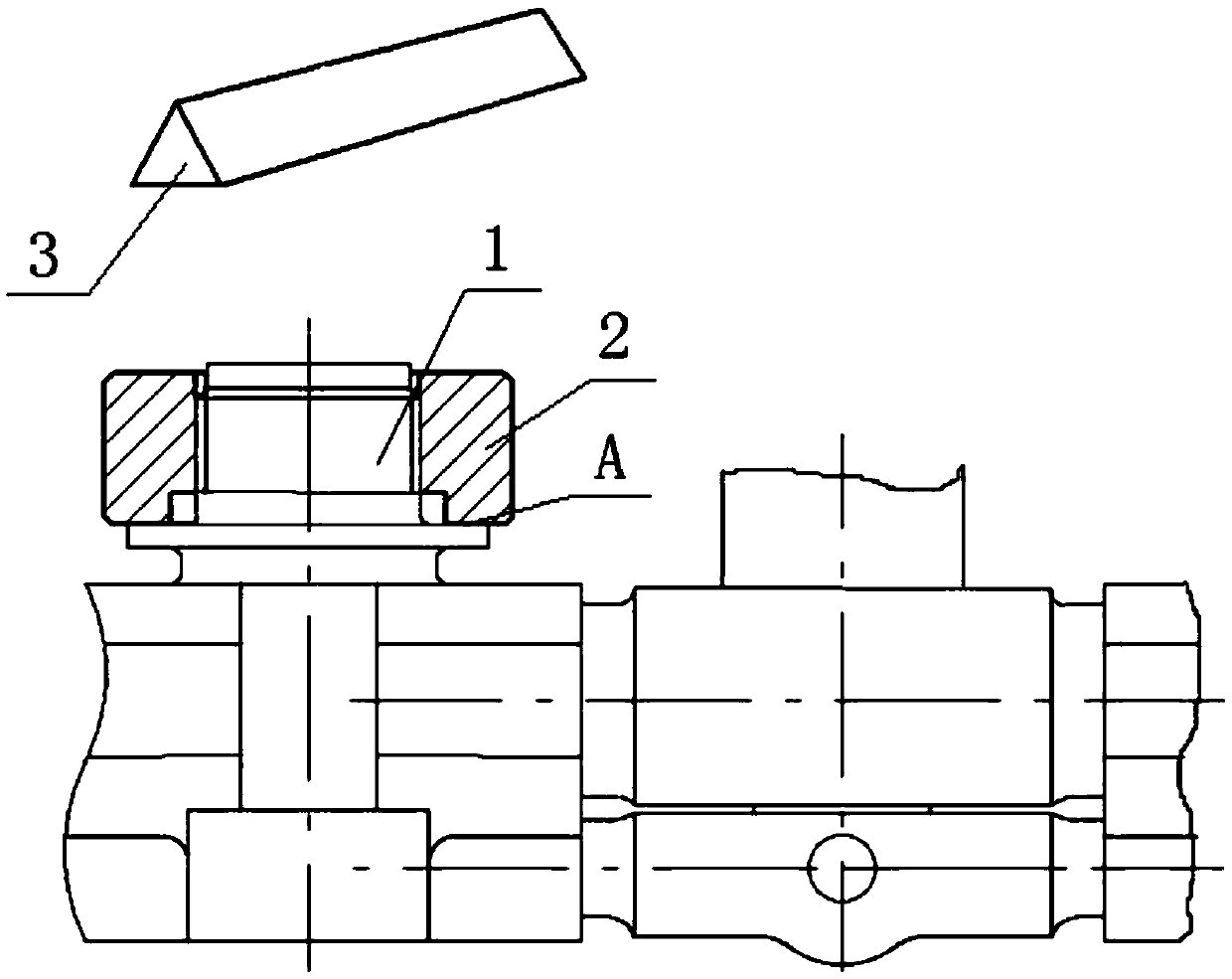

[0021] Such as figure 1 , figure 2 Shown, the grinding method of a kind of annular part of the present invention, its specific method steps are as follows:

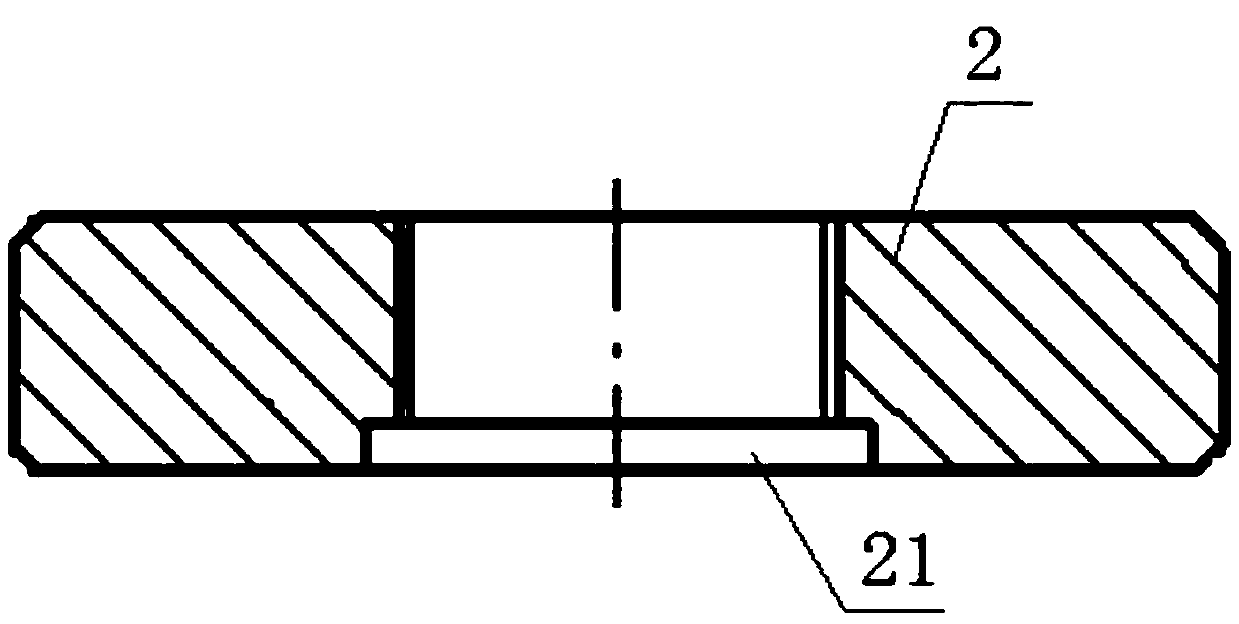

[0022] (1) Design auxiliary tooling: design auxiliary tooling 2 according to the structural shape of ring-shaped part 1 to be ground, the height of auxiliary tooling 2 is the matching height required for ring-shaped part 1 after grinding, and the matching height is Since the grinding surface of the ring-shaped part 1 to be ground is a threaded step surface, the surface to be ground and the reference plane are completed by one machining process, and have good parallelism, so the designed auxiliary tooling 2 is as follows figure 2 Ring with internal thread shown. For ease of assembly, the ring-shaped part 1 may adopt a light ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com