Translation door of sealing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions and beneficial effects of the present invention will be further described and illustrated below in conjunction with the above drawings.

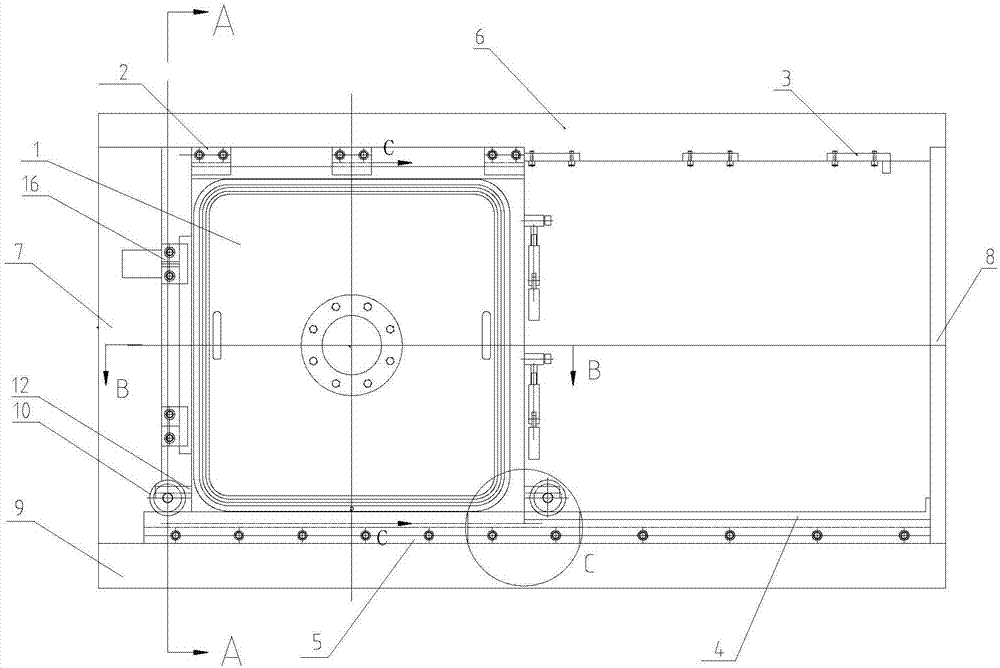

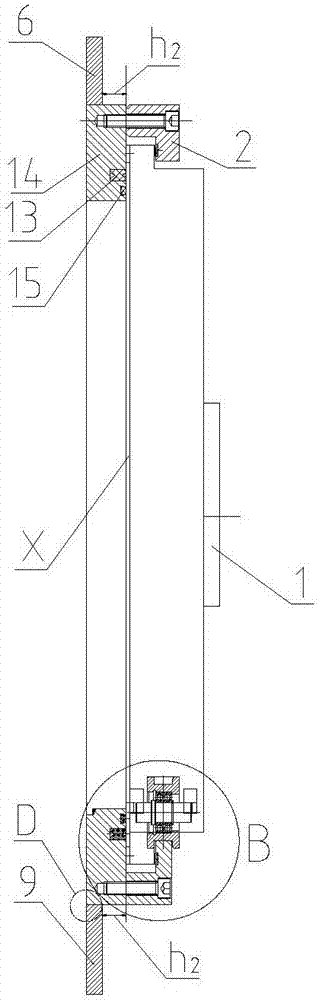

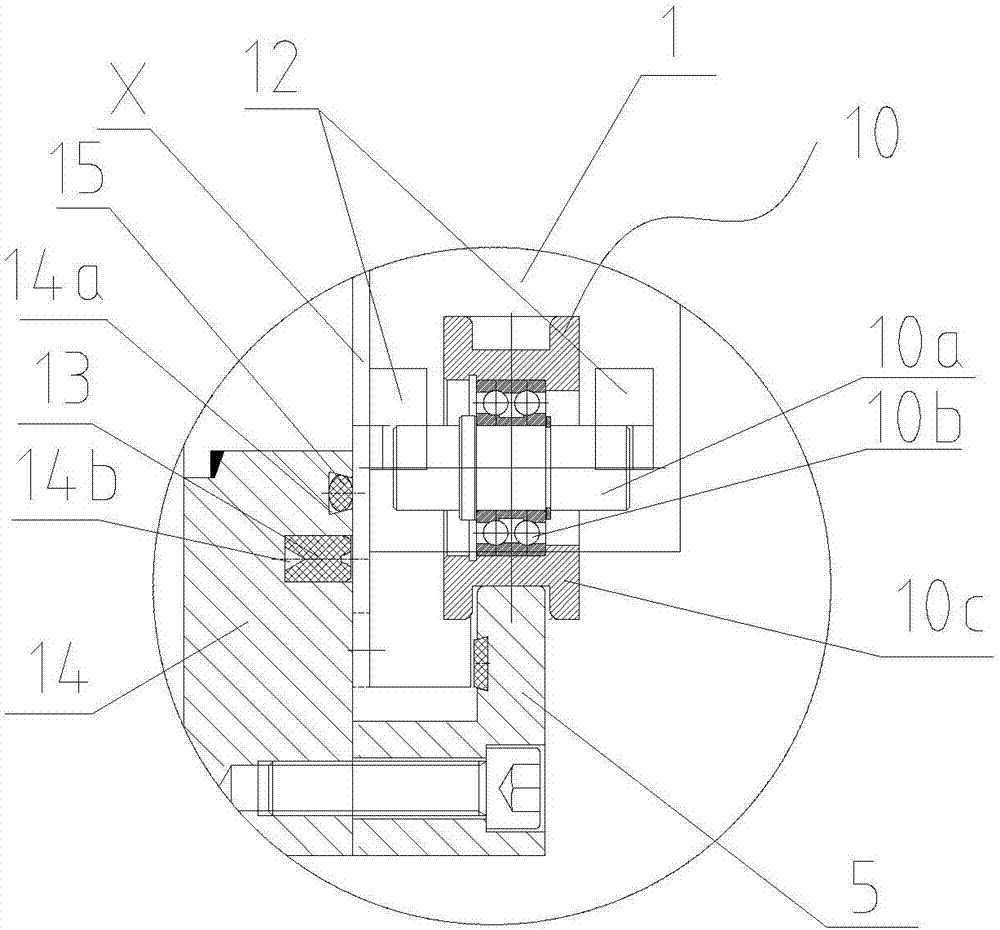

[0055] see figure 1 , 2 , refer to Figure 3-13 , the figure shows a translation door of a sealing device related to the present invention, the key technical solution of which is:

[0056] The translational door of the sealing device comprises a box frame 14 of the sealing device, a docking upper base plate 6, a docking lower base plate 9, a docking left base board 7, a The right base plate 8; the distance h2 between the outer surface of the docked upper base plate 6, the lower base plate 9, the left base plate 7, and the right base plate 8 relative to the outer surface of the box frame 14 are consistent;

[0057] A lower baffle plate 5 is fixed horizontally on the longitudinal left half of the docked lower base plate 9, and a lower guide rail 4 is horizontally fixed on the longitudinal right half of the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com