Engine intake manifold

An intake manifold and engine technology, applied in engine components, engine control, combustion engine, etc., can solve the problems of increased manufacturing difficulty, poor emission, large intake resistance, etc., to improve the mixing of oil and gas and reduce the flow energy Loss, the effect of small air intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

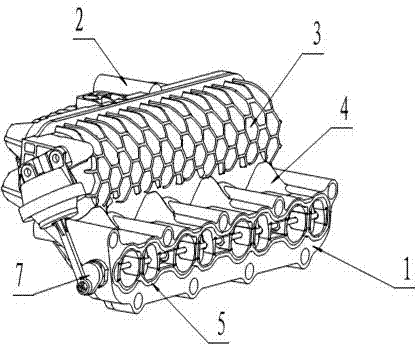

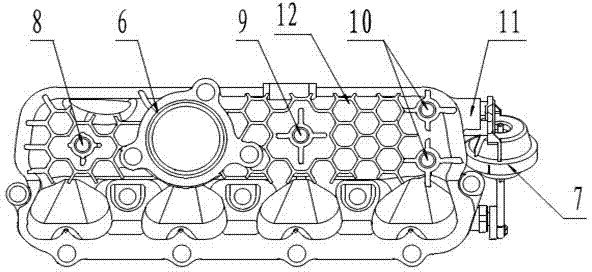

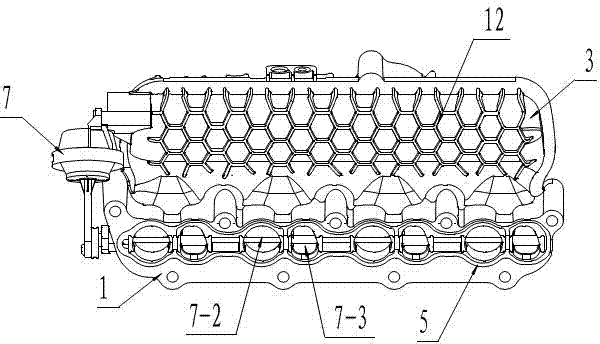

[0024] See Figure 1, figure 2 , the present invention includes an inlet flange 2, a pressure stabilizing chamber 3, an intake branch pipe 4, an outlet flange 1 and an intake swirl adjustment mechanism 7, and the inlet flange 2 is arranged on the same side as the intake branch pipe of the second cylinder of the engine. At the corresponding position, its front end is connected to the intake pipe behind the engine air filter, and its rear end is connected to the air inlet of the pressure stabilizing chamber. A group of intake branch pipes 4 are arranged on the opposite side walls, the rear ends of the intake branch pipes 4 communicate with the outlet flange 1, the axis of the intake branch pipe and the axis of the outlet flange form an included angle of 135°, and the outlet flange 1 is connected with the intake port of the engine cylinder head.

[0025] see Figure 1 to Figure 7 , the present invention is a cavity structure formed by vibration friction welding of upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com