Vessel capable of releasing negative pressure automatically

An automatic release and negative pressure technology, applied in the directions of cover with auxiliary device, sealing member with auxiliary device, closing, etc., can solve the problems of complex structure, increase assembly time, increase production cost, etc., and achieve simple and simple structure. The effect of avoiding pollution and reducing intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

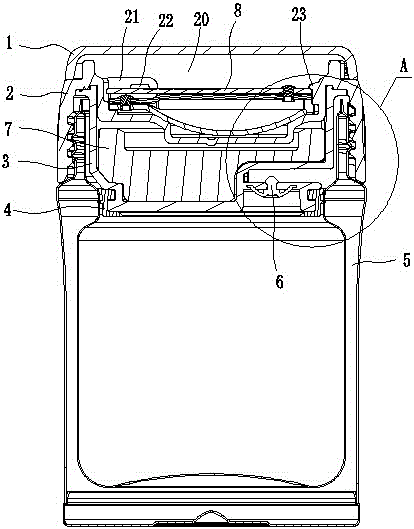

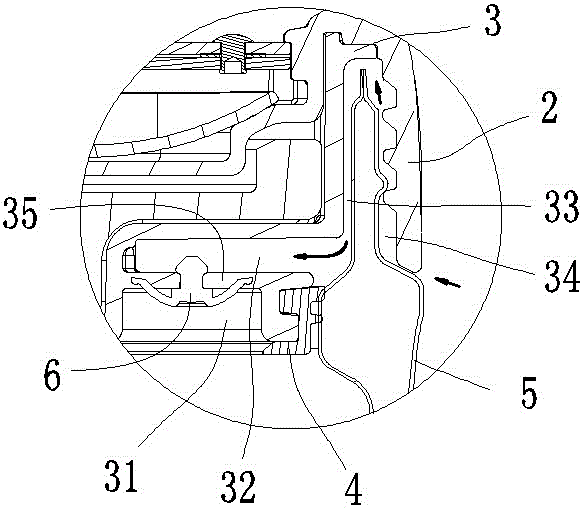

[0013] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached figure 1 and 2 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0014] The present invention is a container for automatically releasing negative pressure, including a container 5 and a cup cover, the cup cover includes a top cover 1, a cover body 2 and an inner cover 3, the top cover 1 is screwed to the top of the cover body 2, The cover 2 is screwed to the outside of the container opening, and the top surface of the cover 2 is recessed downward to form a cavity 20 for accommodating tableware. The upper end of the inner cover 3 is connected to the cover 2, and the lower end of the inner cover 3 Extending in the opening of the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com