Air inlet manifold and automobile engine

A technology of intake manifold and air inlet, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing intake pressure loss, poor uniformity, and unfavorable uneven pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

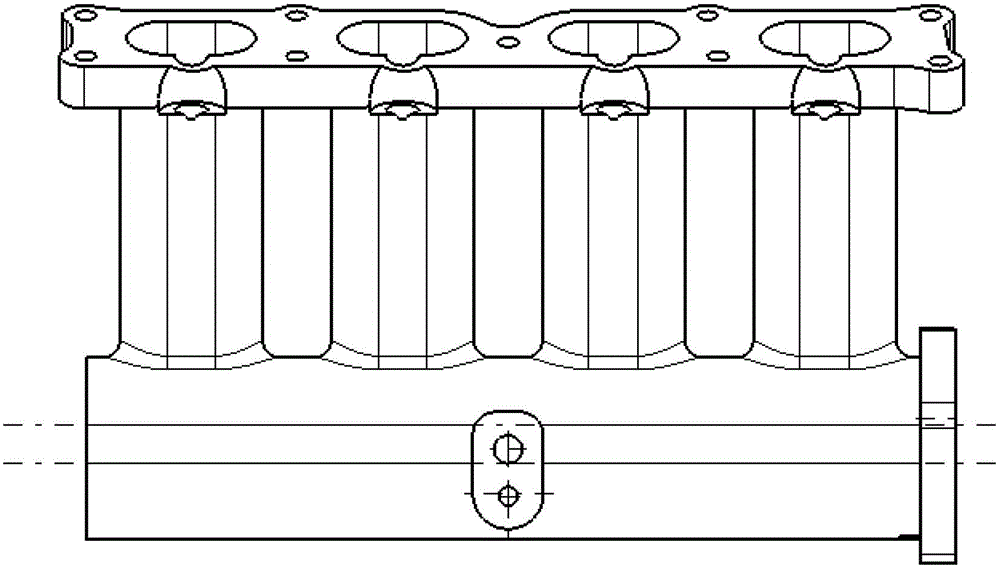

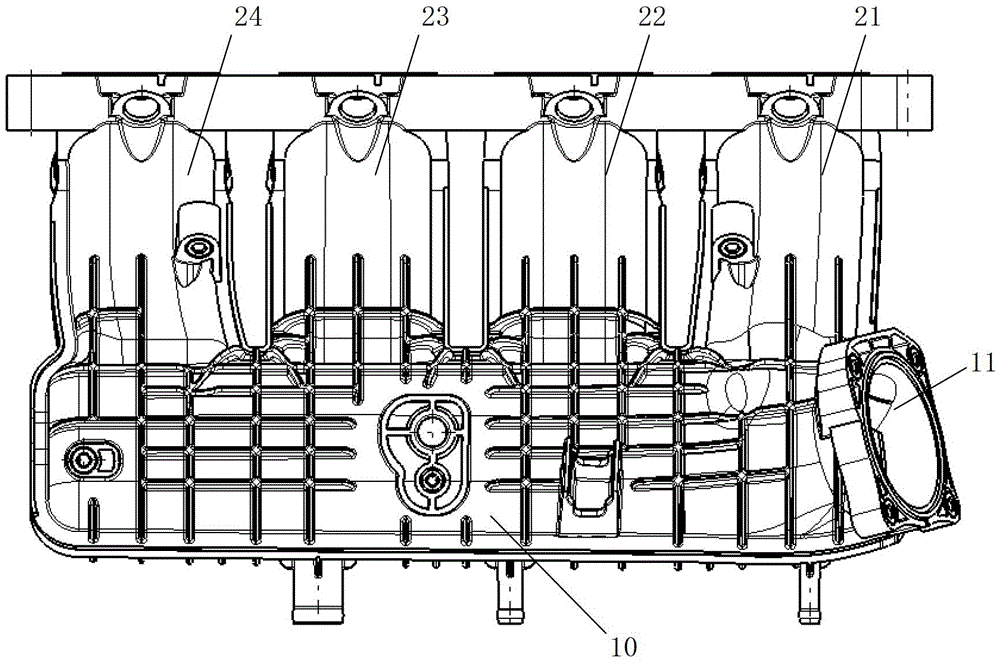

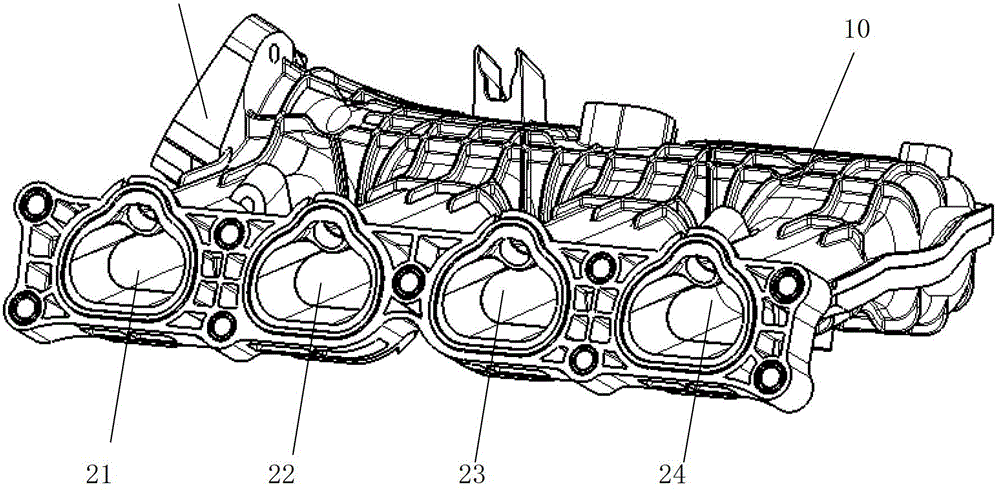

[0030] Such as Figure 2 to Figure 7 As shown, in order to solve the problems of unreasonable design of intake manifold airway structure, large intake pressure loss and poor intake uniformity in the prior art, the embodiment of the present invention provides an intake manifold, including a plenum chamber 10 and At least two air passages (such as air passages 21, 22, 23, 24) communicating with the pressure stabilizing chamber 10, and the air inlet 11 for connecting with the throttle valve is provided on the stabilizing chamber 10, wherein, the air passage and the stabilizing chamber The junction of the chamber 10 adopts an unequal rounded structure that allows the gas to be evenly distributed to each air channel after being stabilized in the pressure stabilizing chamber through the air inlet. The unequal fillet structure adopts unequal fillet radii at the transition joint between the air passage and the plenum chamber 10 . The airway structure is designed with unequal rounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com