Safety linkage locking device for quick valve of pressure vessel

A pressure vessel and locking device technology, applied in the field of pressure vessels, can solve problems such as hindering structure popularization, failure, manufacturing errors, etc., and achieve the effect of convenient operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

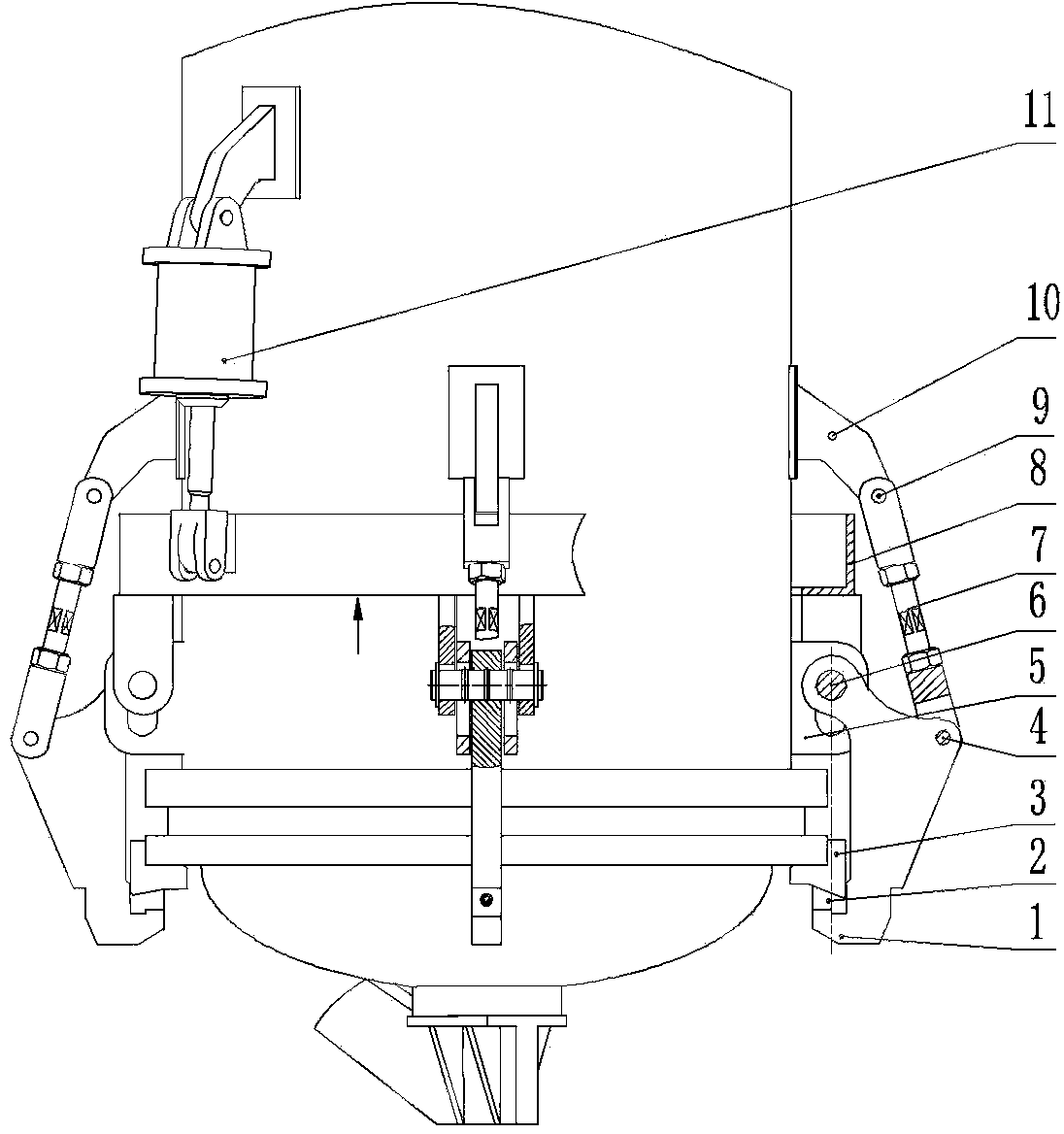

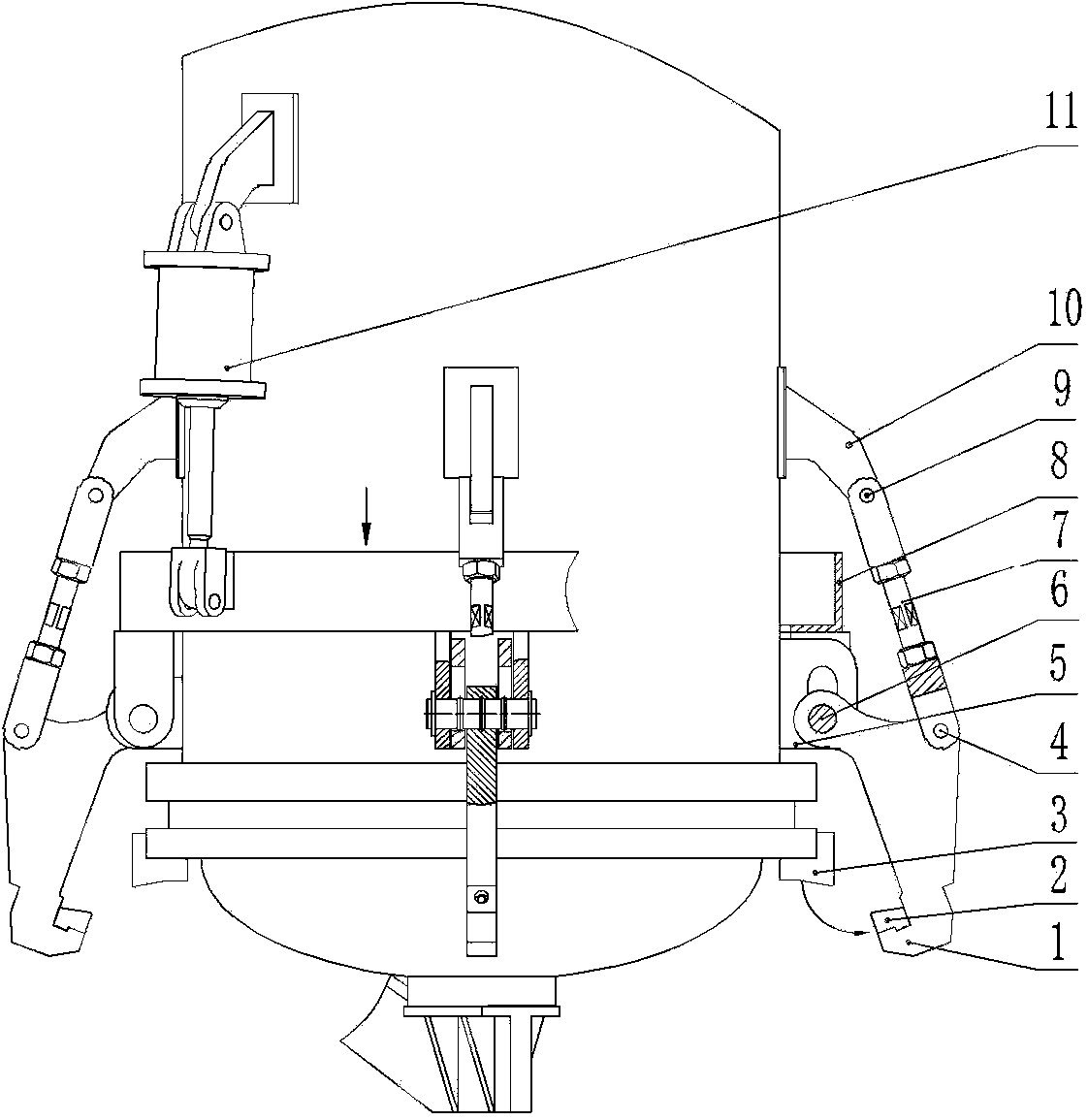

[0031] Such as Figure 1-4 As shown, the present invention provides a quick-open door safety linkage locking device for a pressure vessel, which includes a locking hook 1, an inclined iron 2, an inclined pad iron 3, a first pin shaft 4, a long-hole lifting lug 5, and a second pin shaft 6. Pull rod 7, sliding ring 8 (circular or polygonal, etc.), third pin 9, fixed lifting lug 10 and cylinder 11;

[0032] Both the long hole lifting lug 5 and the fixed lifting lug 10 are fixedly installed on the outer wall of the pressure vessel; the long hole lifting lug 5 is provided with a long hole; the sliding ring 8 is driven by the cylinder 11 to move up and down in a straight line;

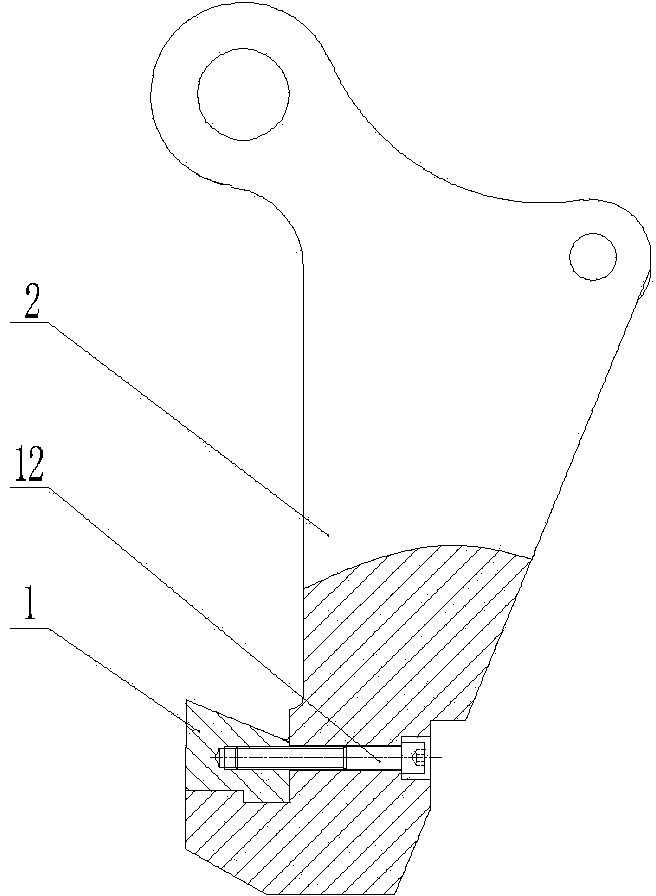

[0033] The locking hook 1 includes a hook head end, a hook tail end and a curved rod connecting the hook head end and the hook tail end; the inclined iron 2 is fixedly arranged on the hook head end of the locking hook 1 through a locking screw 12; The iron 3 is installed on the flange of the pressure vessel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com