A low-density high-strength phenolic resin airgel with extremely low shrinkage and a normal-pressure drying preparation method

A phenolic resin, atmospheric drying technology, applied in the field of low-density and high-strength phenolic resin aerogel drying under atmospheric pressure, can solve problems such as shrinkage and cracking, and achieve the effect of large porosity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

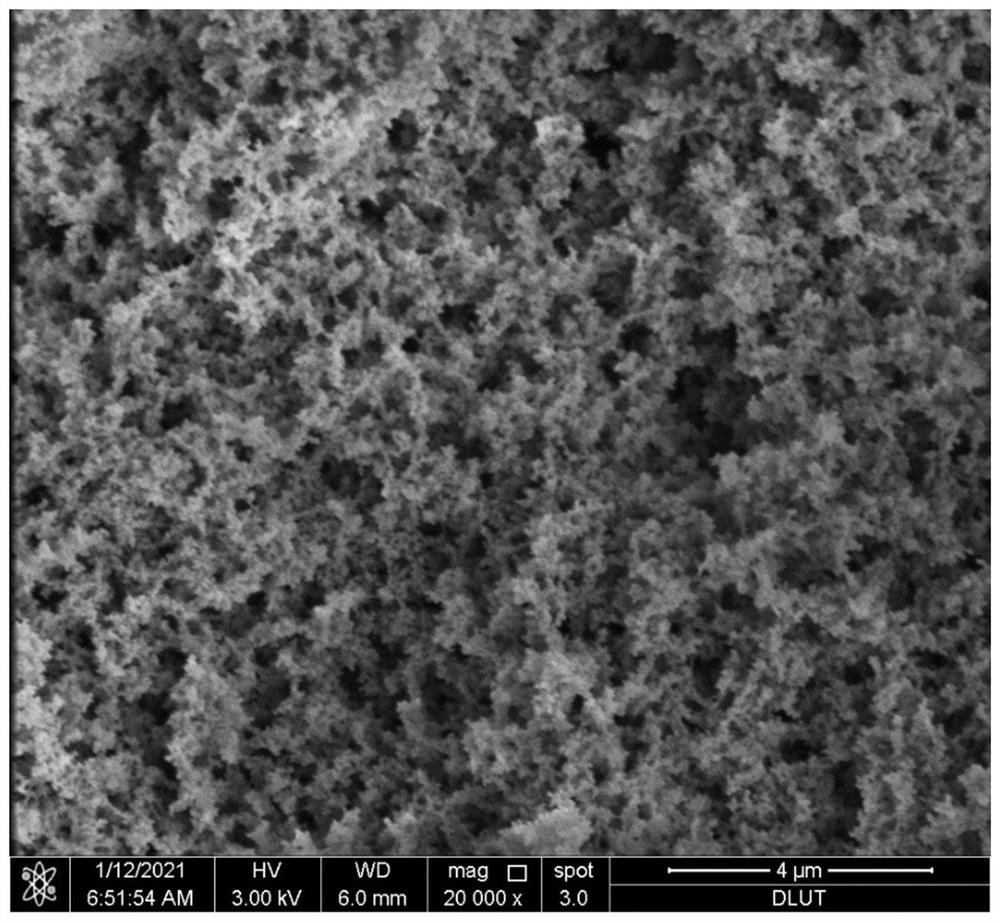

[0034] In this example, two kinds of phenolic resin aerogels with thermosetting phenolic resin and without thermosetting phenolic resin were prepared respectively. The specific implementation is as follows:

[0035] (1) Add 1.5g of powdered thermoplastic phenolic resin and 0.214g of powdered thermosetting phenolic resin into 10ml of ethylene glycol solution as the first group (containing thermosetting phenolic resin), and add 1.714g of powdered thermoplastic phenolic resin , added to 10ml of ethylene glycol solution as the second group (without thermosetting phenolic resin, and the total content of phenolic resin resin in the two groups of solutions should be the same), put the two groups of phenolic resin solutions on a heating platform at 150°C and heat for 30min After cooling, 0.214 g of hexamethylenetetramine was added to the two groups of solutions, and dissolved by ultrasonic vibration for 3 hours to obtain the precursor solution;

[0036] (2) Pour the prepared precurso...

Embodiment 2

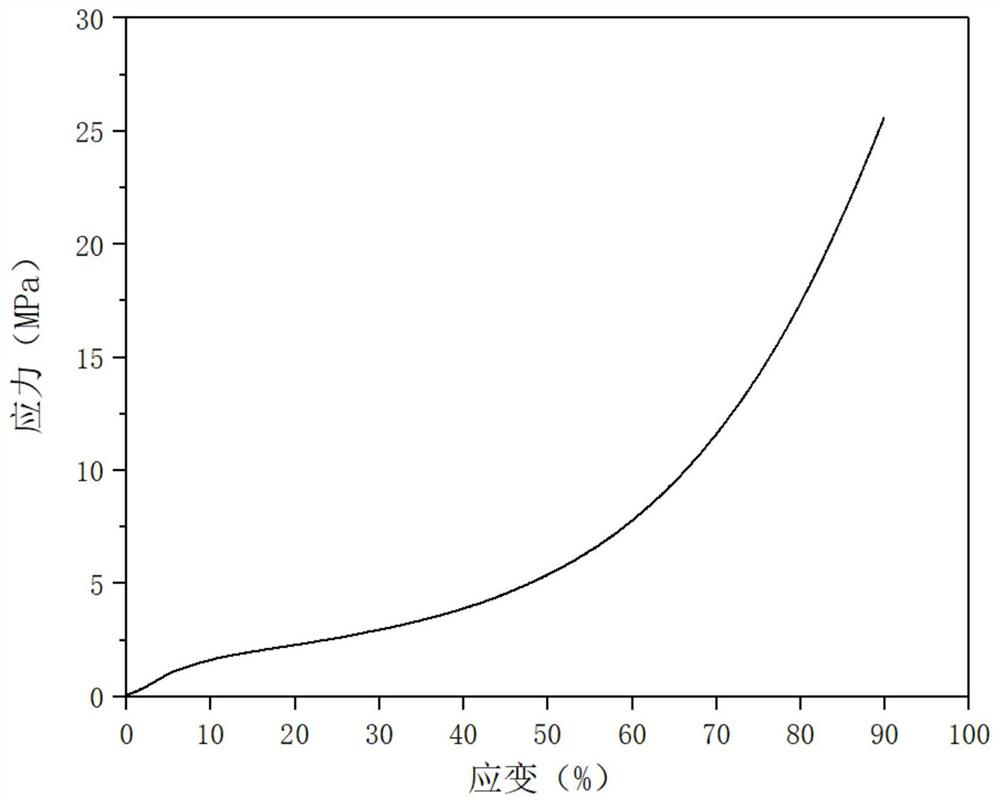

[0041] This implementation case tests and compares the compressive properties of several phenolic resin airgels with different contents of thermosetting phenolic resin or hexamethylenetetramine (such as Figure 5 shown), the stronger the compressive capacity of the phenolic resin airgel, the stronger the ability to resist drying shrinkage under normal pressure, and the compressive stress-strain curve can further prove that the added thermosetting phenolic resin can enhance the airgel skeleton strength The way to resist the shrinking capillary force generated during the drying process. The specific implementation is as follows:

[0042] (1) Weigh 5 groups of thermoplastic phenolic resins with a mass of 1.5g respectively, add 0.428g of thermosetting phenolic resin to the first 3 groups, and add 0.214g of thermosetting phenolic resin to the remaining group (that is, group 4). For phenolic resin, add 0.642g of thermosetting phenolic resin to the last remaining group (namely Group...

Embodiment approach

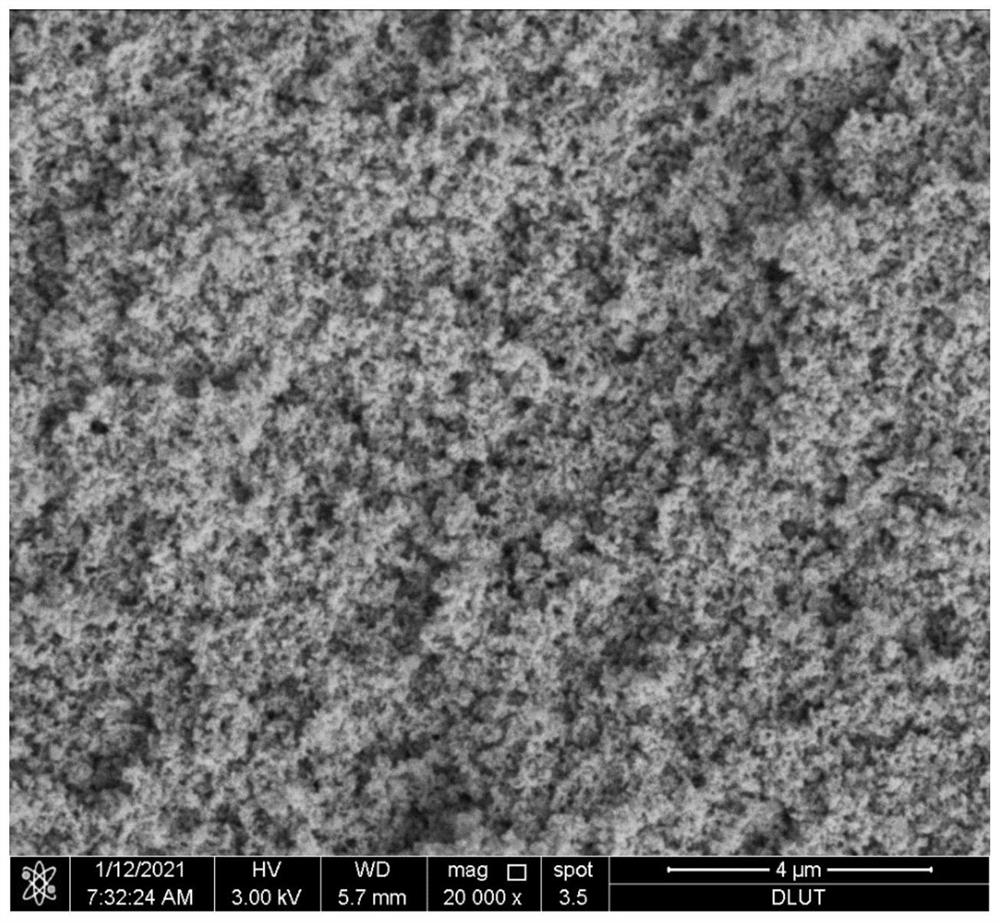

[0049] In this example, a precursor solution (containing thermosetting phenolic resin) with a lower concentration of phenolic resin was used to prepare a low-density, high-strength phenolic resin aerogel with extremely low shrinkage ( Figure 6 ), the specific implementation is as follows:

[0050] (1) Add 1.166g of powdered thermoplastic phenolic resin and 0.334g of powdered thermosetting phenolic resin to 10ml of ethylene glycol, and place it on a heating platform at 150°C for 30 minutes, and add 0.2332g of it after cooling Hexamethylenetetramine, and assisted dissolution by ultrasonic vibration for 2h, to obtain the precursor solution;

[0051] (2) Pour the prepared precursor solution into an airtight container, incubate in a heating box at 120°C for 1 hour, and incubate at 150°C for 3 hours to obtain a phenolic resin wet gel;

[0052] (3) Take out the cross-linked phenolic resin wet gel and soak it in 50ml of absolute ethanol, and place it on a heating platform at 150°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com