Food producing thermal insulation cylinder with ball grinding function

A functional and ball-carrying technology, applied in the fields of application, food science, cocoa, etc., can solve problems affecting production efficiency, high frequency of use, and immature design, etc., to achieve enhanced agitation effect, maintain structural characteristics, and be easy to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

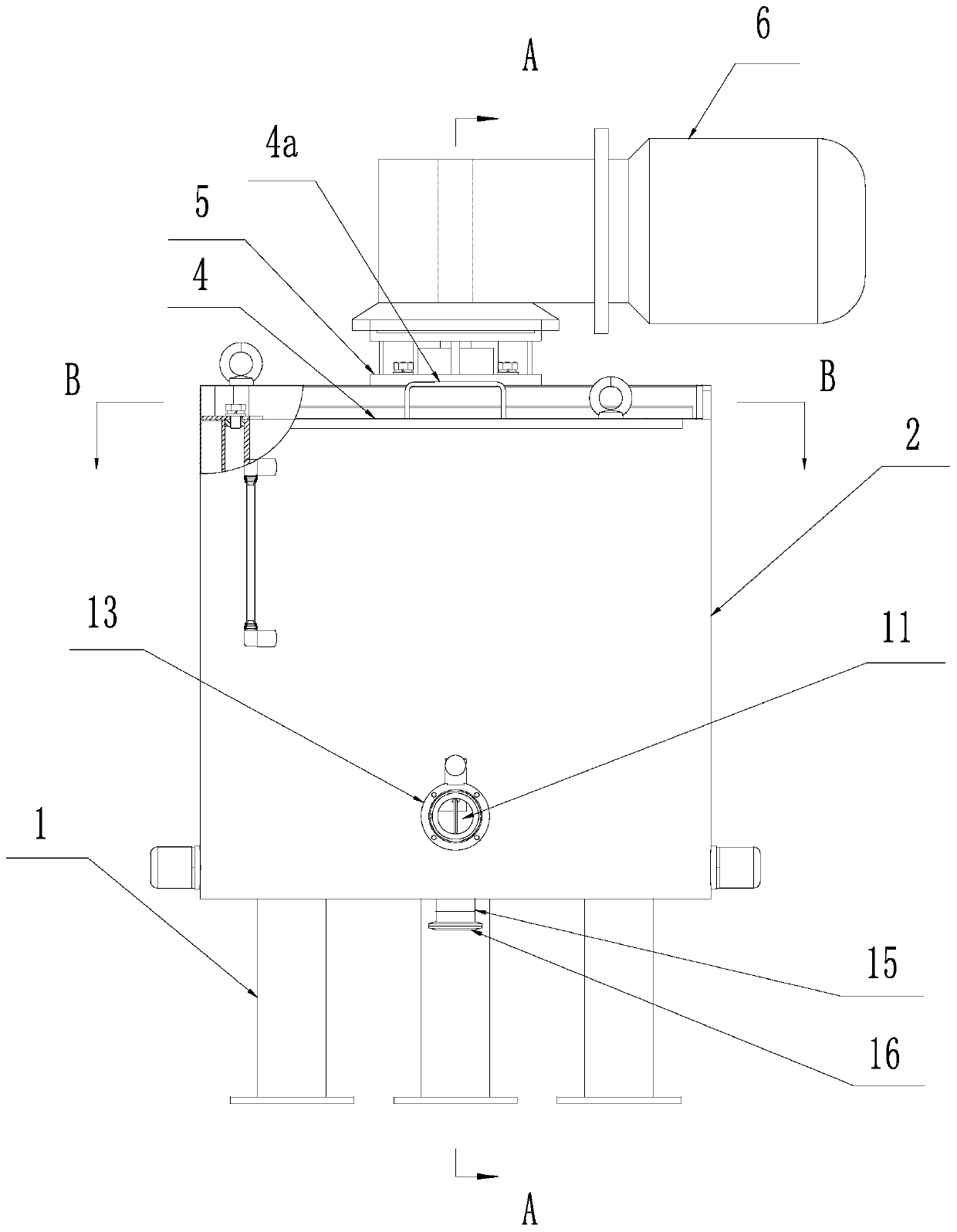

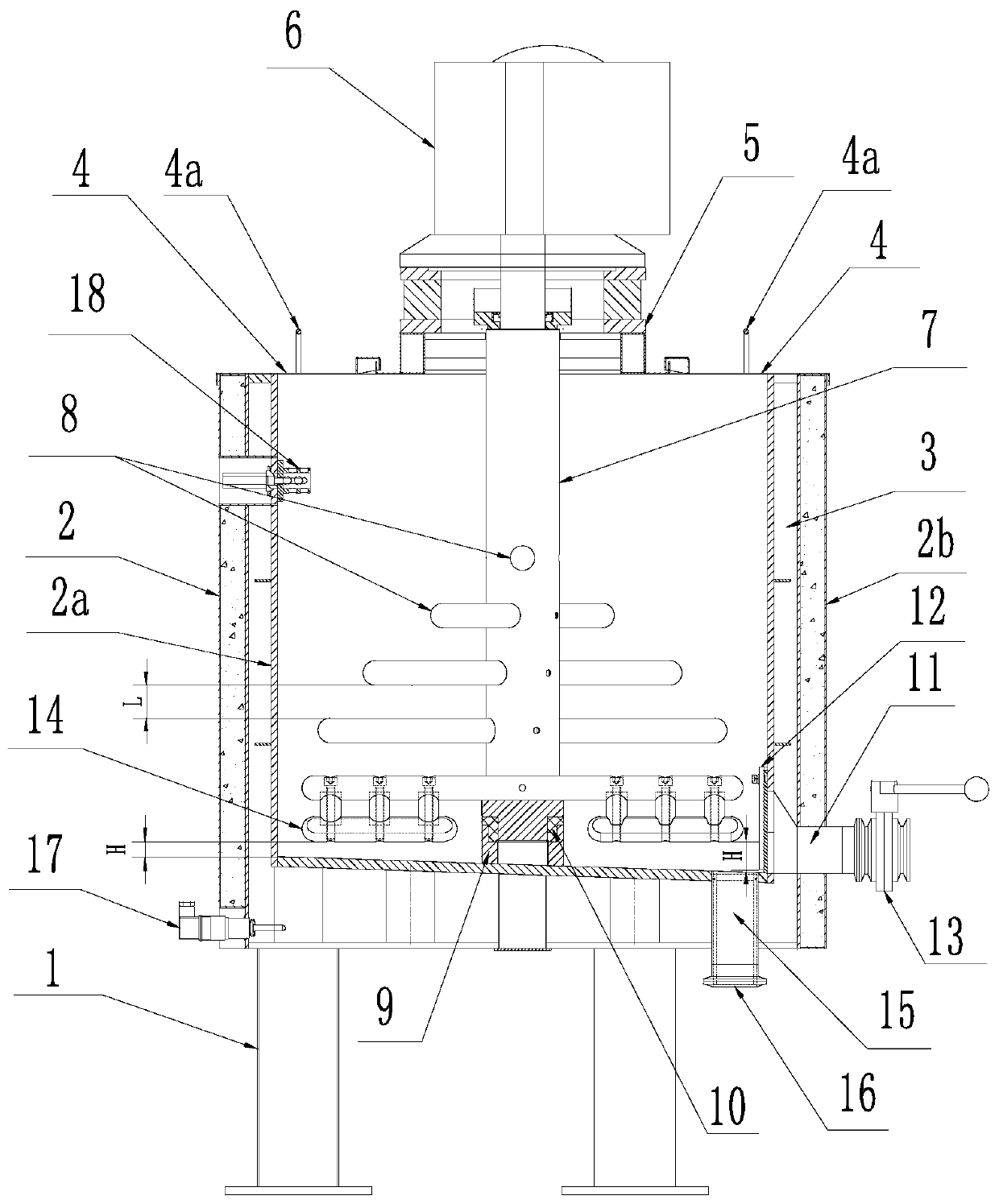

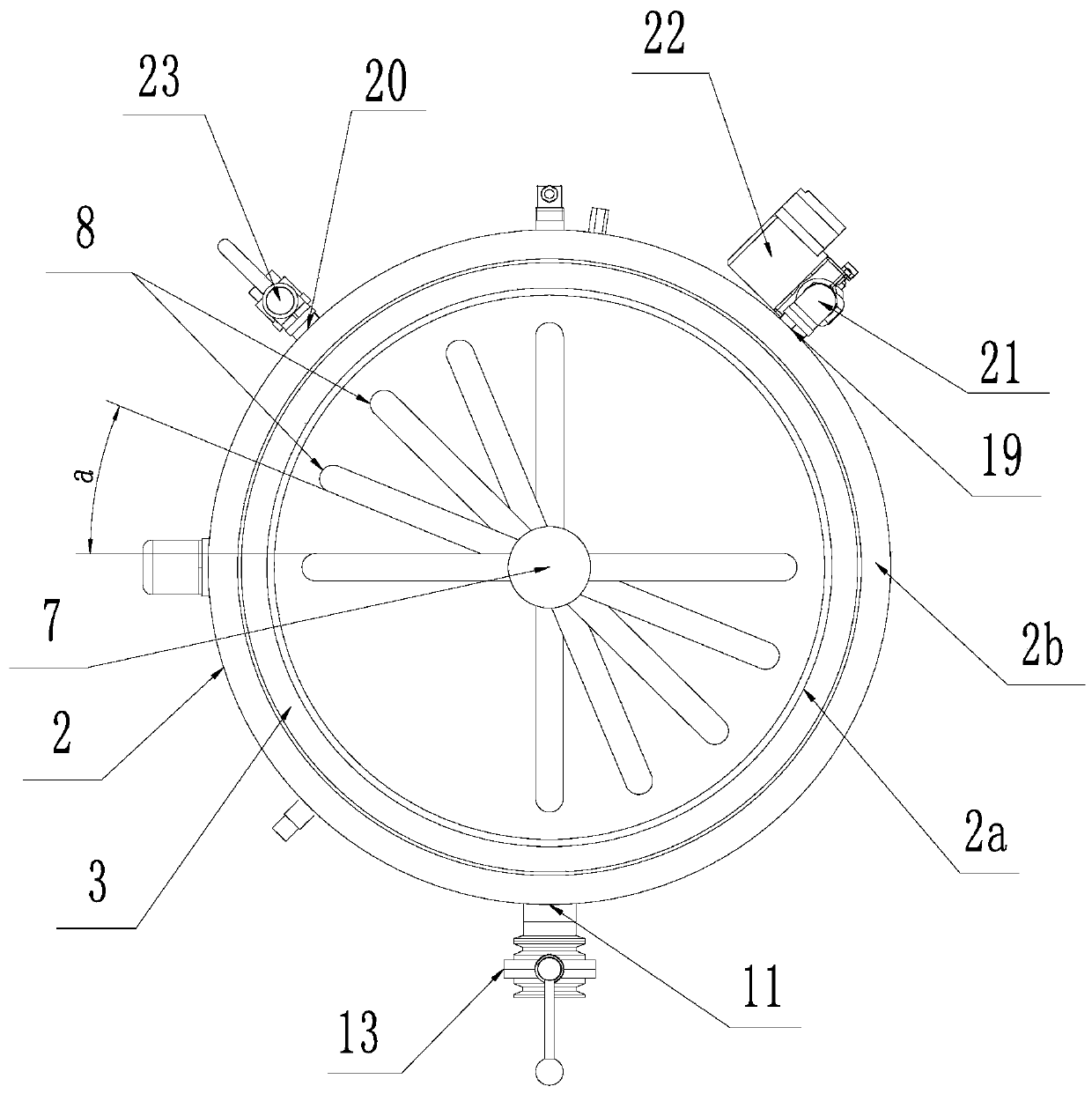

[0029] Example: Combine Figure 1~Figure 3 As shown, the specific implementation of the food production insulation cylinder of this ball milling function provided by the invention is described as follows:

[0030] Like the existing thermal insulation cylinder, it has a vertically arranged cylinder body 2 supported by a bracket 1 and with a heat-insulating water interlayer 3. This cylinder body 2 is composed of an inner tank 2a with an open top and an inner tank 2a on the periphery of the inner tank 2a. The thermal insulation shell 2b is jointly formed, and the thermal insulation water interlayer 3 is located between the thermal insulation shell 2b and the inner tank 2a. The lower side of the heat preservation shell 2b is fixed with a temperature measuring probe 17 extending into the heat preservation water interlayer 3 and located below the liner 2a, while the upper side of the heat preservation shell 2b is fixed with a liquid level probe 18 extending into the liner 2a. and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com