Modified spherical carbon particle material, preparation method thereof, graphene-based water-based conductive ink containing modified spherical carbon particle material and preparation method of graphene-based water-based conductive ink

A conductive ink, ethylenic water-based technology, applied in the direction of ink, conductive coating, fibrous filler, etc., can solve the problem of reducing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

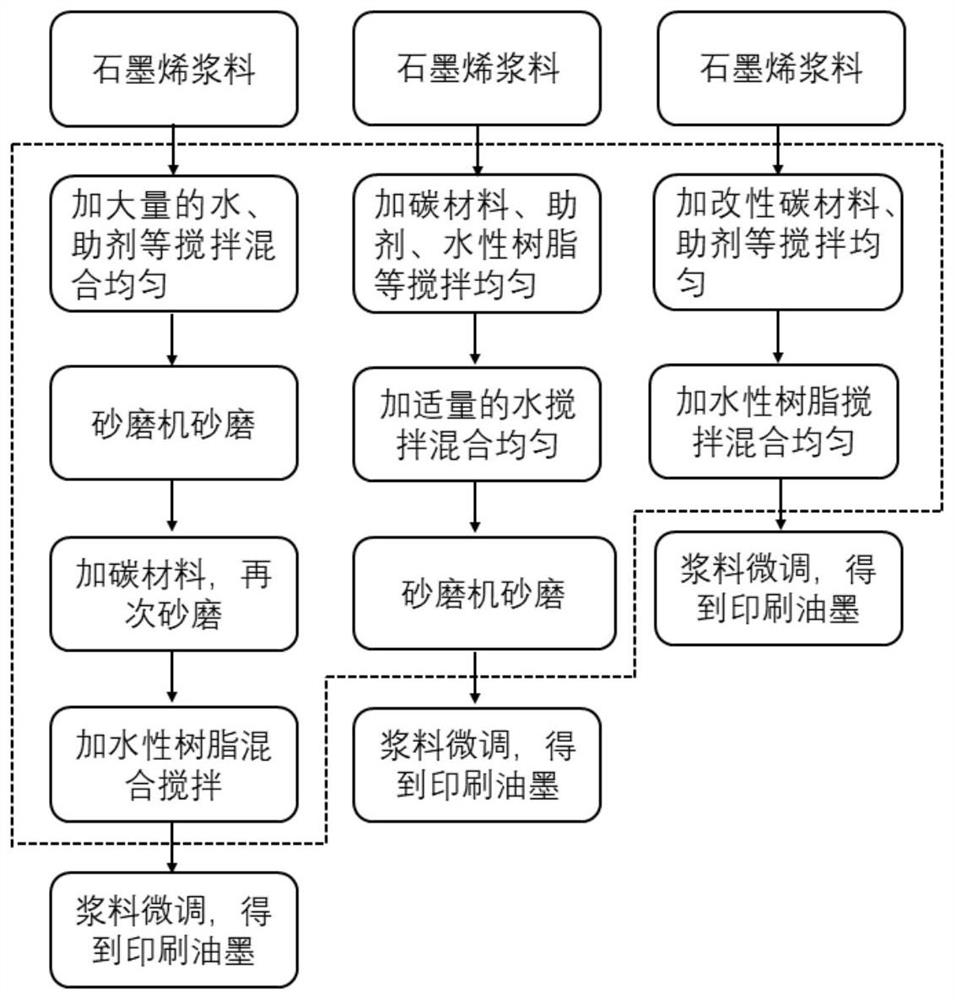

[0051] Such as figure 1 As shown in the left column, a typical graphene-based water-based conductive ink preparation method includes the following steps: add a large amount of water, additives, etc. to the graphene slurry and mix evenly; use a sand mill to sand the resulting mixture Adding carbon material, sanding again; adding water-based resin for mixing and stirring; and fine-tuning the slurry to obtain printing ink.

[0052] It can be seen that when the water-based system is used, the unmodified graphene slurry has high viscosity and poor fluidity, and it is basically difficult to use it directly. It is usually necessary to add a large amount of water to obtain the initial fluidity and processability of graphene during use. Therefore, the solid content of the prepared conductive ink is low, which leads to problems such as thin dry thickness of the single-printed coating, long drying time, and poor film quality in the subsequent preparation of the conductive coating, which ...

Embodiment 1

[0078] 5Kg of the purchased conductive carbon black (IMERYS, Super P Li) is placed in an airtight stirring tank, adding a solid content of 50% polyethylaniline aqueous solution 5Kg, stirring under airtight conditions until the temperature in the tank rises to 80 Celsius, stop stirring, slowly cool down to room temperature; add about 300g of pH adjuster (DOW, AMP-95) into the above system, stir and mix evenly to obtain a weakly alkaline modified conductive carbon black slurry with a pH of about 8-9 material;

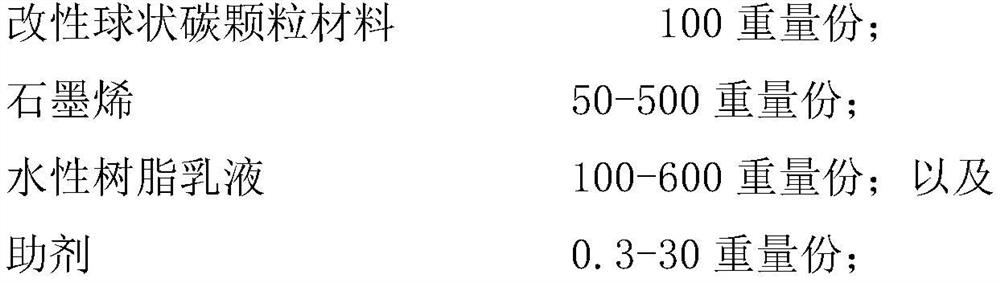

[0079] Take the modified conductive carbon black prepared above as raw material, weigh 1Kg in a stirring tank, then add 28Kg of graphene slurry with a solid content of 5% (Mexi Technology, ESOE-5), add additives (defoamer , BYK-011, 14g; leveling agent, BYK-349, 21g) and then vigorously stirred until evenly mixed to obtain a carbon-based mixed slurry with good fluidity; then add a water-soluble acrylic emulsion with a solid content of 40% (Zhongen Chemical industry, BA-8...

Embodiment 2

[0082] 5Kg of graphite purchased (Shanghai Huiping, KS-6) was placed in an airtight stirring tank, and 5Kg of polyethylaniline aqueous solution with a solid content of 50% was added, and stirred under airtight conditions until the temperature in the tank rose to 85 Celsius, stop stirring, slowly cool down to room temperature; add 500g of pH adjuster (DOW, AMP-95) to the above system, stir and mix evenly to obtain a weakly alkaline modified conductive carbon black slurry with a pH of about 9-10 ;

[0083]Taking the modified conductive carbon black prepared above as raw material, weigh 1.1Kg in a stirring tank, then add 16Kg of graphene slurry with a solid content of 5% (Mexi Technology, ESOE-5), add additives (defoaming agent, BYK-011, 80g; leveling agent, BYK-349, 120g) and then vigorously stir until mixed evenly to obtain a carbon-based mixed slurry with good fluidity; then add a water-soluble styrene-acrylic emulsion with a solid content of 35% ( Ecosol, BS-104) 1.7Kg, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com