Process for fabricating wind-driven generator base

A technology of wind turbine and processing technology, applied in the field of mechanical processing, can solve the problems of easy deformation, failure to meet the design requirements of the machine base, poor processing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The processing technique of wind power generator support of the present invention adopts following process steps:

[0039] 1. Milling foot process

[0040] 1. Frame: 1.5MW water-cooled wind turbine frame (cylindrical structure), after coiled with 6-20mm Q235 or Q 345C steel plate, round flanges are welded on both ends, and welded into a structural frame; blank size : 1700mm (length) × 920mm (width) × 1080mm (height); the blank size of the inner hole: Φ790mm, the center height of the blank: 456mm;

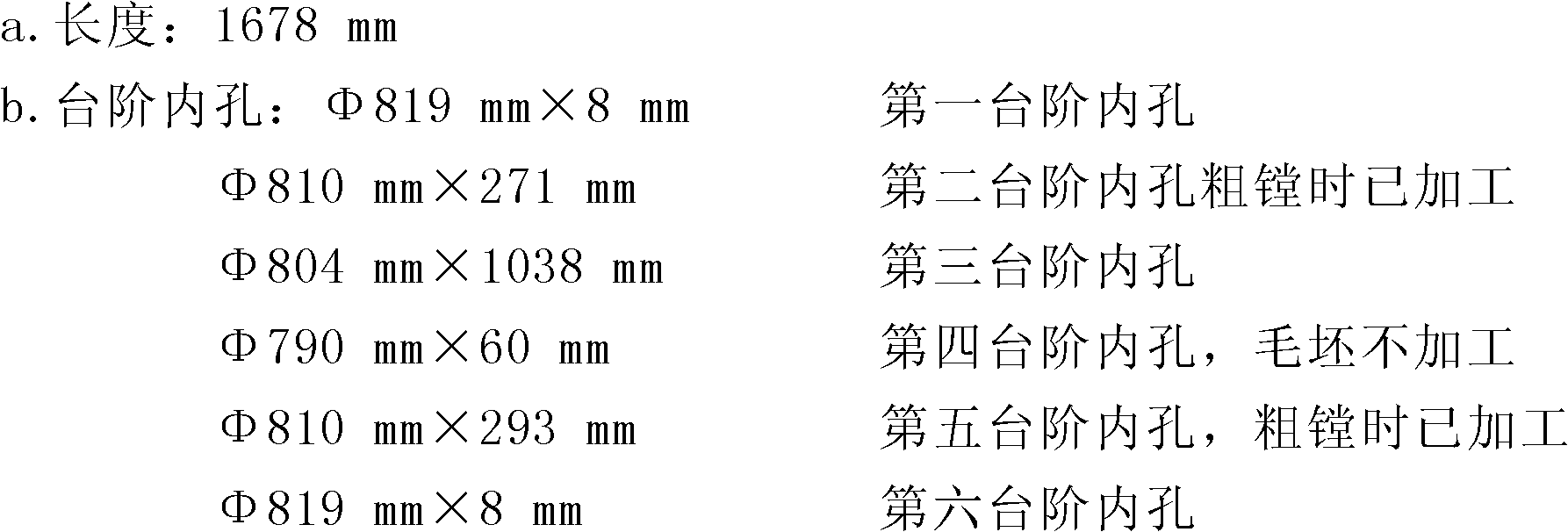

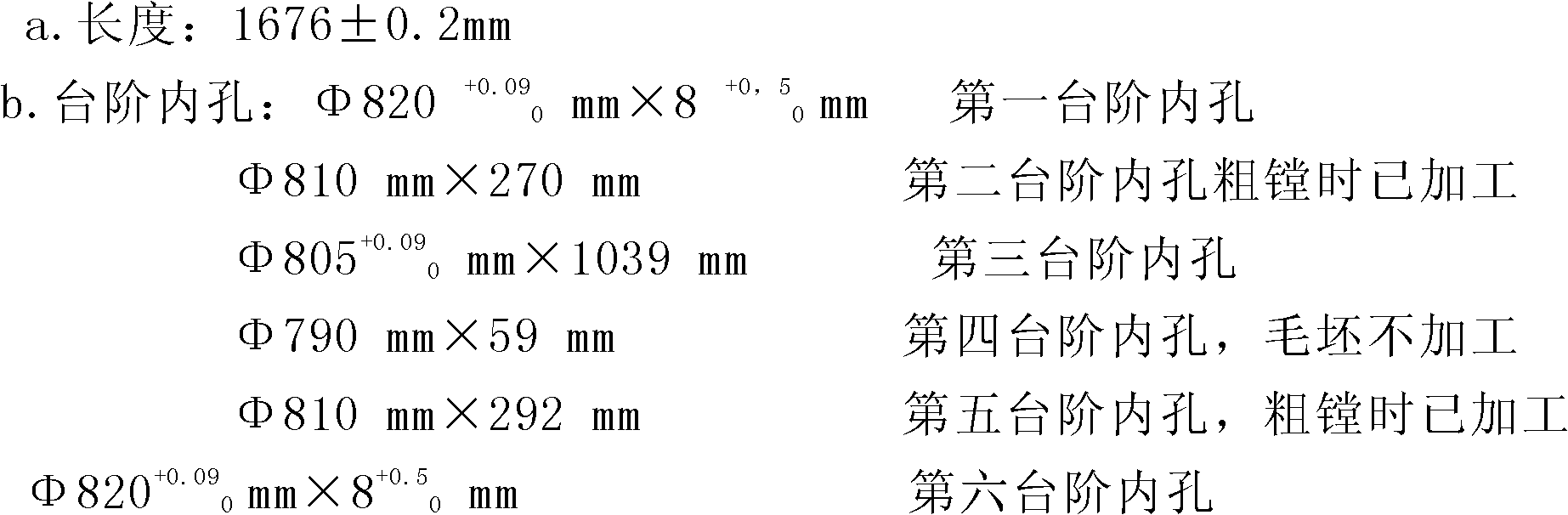

[0041] The inner hole of the water-cooled machine base is a cylinder rolled from steel plate, and round flanges are welded on both ends. The installation principle of the wind power generator is: install the end cover of the generator at both ends of the base, install the motor stator in the middle of the inner hole, install the windshield and the cooling fan at the tail. Because the diameters of the installed components are different, the machine base should be processed i...

Embodiment 2

[0075] Adopt the processing step of the processing technology of water-cooled wind-driven generator support described in embodiment one, can process 3MW air-cooled wind-driven generator support;

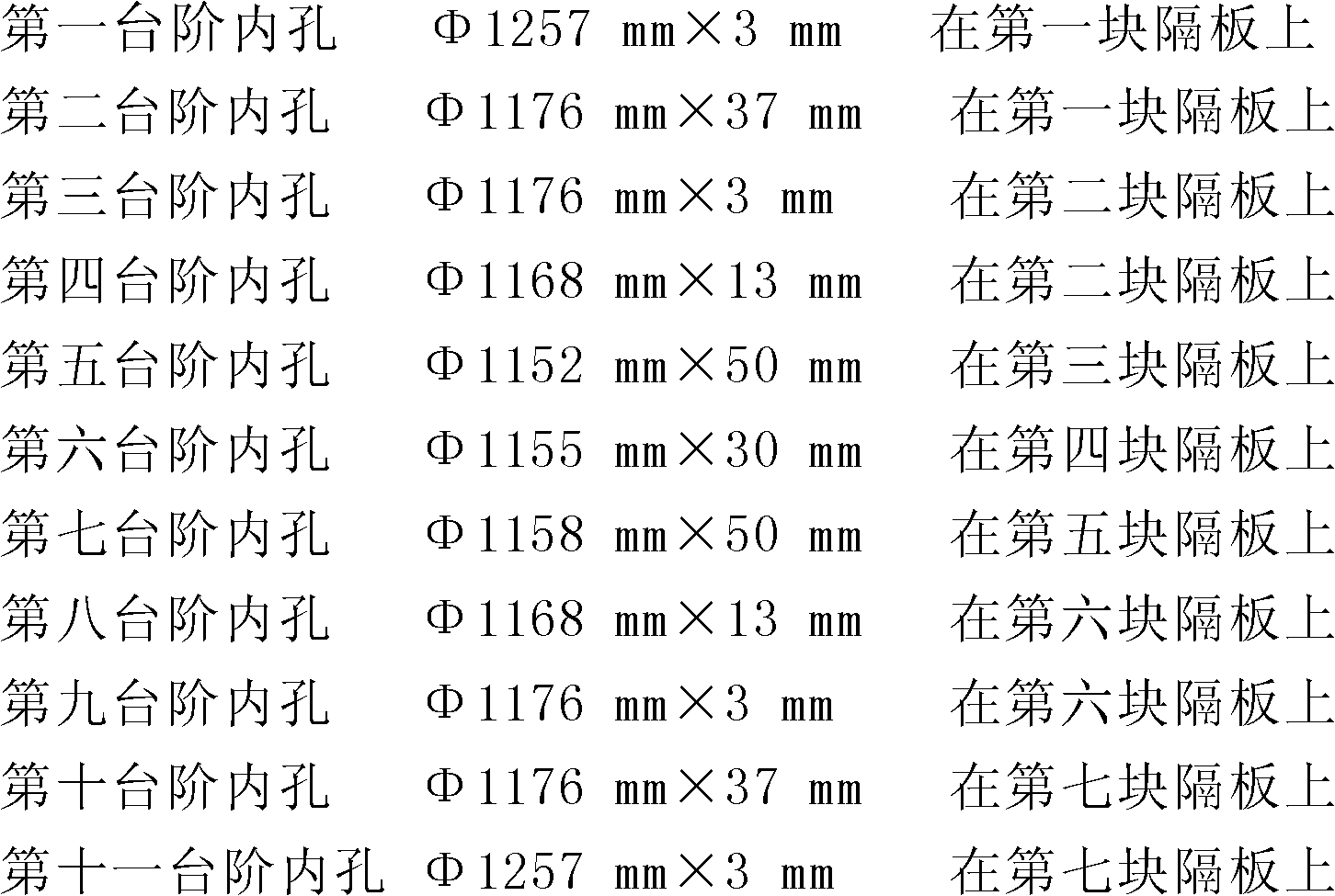

[0076] The frame of the 3MW air-cooled wind turbine is welded with 20mm-50mm Q235 or Q 345C steel plates into a box-shaped structure; the inside of the box-shaped structure is composed of various partitions, and there are cavities between the partitions. The components installed on the inner holes of each partition plate in the inner cavity are the same as the water-cooled machine base. According to the diameter size and installation position of each component, various inner hole sizes of each partition plate in the inner cavity are formed by processing.

[0077] 1. Dimensions of blank: 2120mm (length) × 1300mm (width) × 1285mm (height)

[0078] Blank center height: 638mm

[0079] 2. The rough size of the inner hole of each partition in the square box:

[0080] Inner hole of the f...

Embodiment 3

[0096] Adopt the processing steps of the processing technology of the water-cooled wind power generator base described in the first embodiment, after coiling with 6-20mm Q235 or Q 345C steel plate, round flanges are welded at both ends, and welded into a 2MW water-cooled cylindrical structure Type wind turbine frame; process 2MW water-cooled wind turbine frame according to the diameter size and installation position of each component.

[0097] 1. Dimensions: length 1650mm × width 1250mm × height 1345mm

[0098] 2. Inner hole blank size: Φ840mm

[0099] 3. The height of the blank center: 505mm

[0100] 4. Dimensions from milling foot plane to center height: 500 0 -0.5 mm

[0101] 5. Rough boring size:

[0102]

[0103] 6. Semi-fine boring size:

[0104]

[0105]

[0106] 7. Fine boring size:

[0107]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com