Double herringbone gear in-phase processing method

A technology of herringbone gears and herringbone teeth, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problem of low co-phase accuracy of double herringbone gears, and achieve high co-phase precision and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

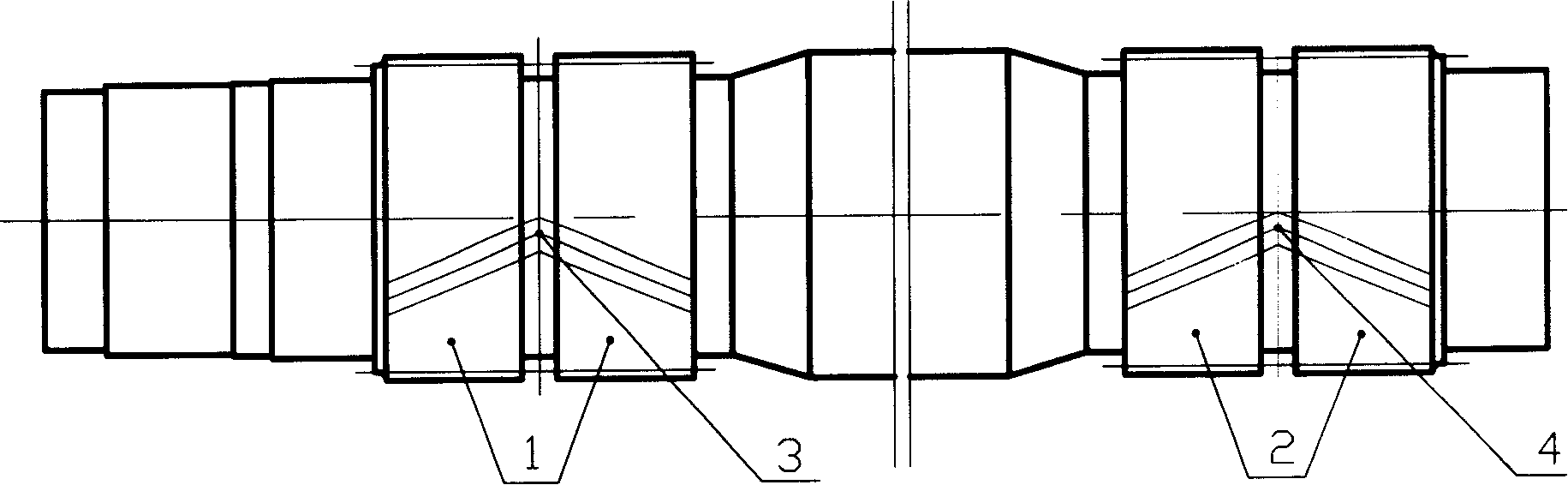

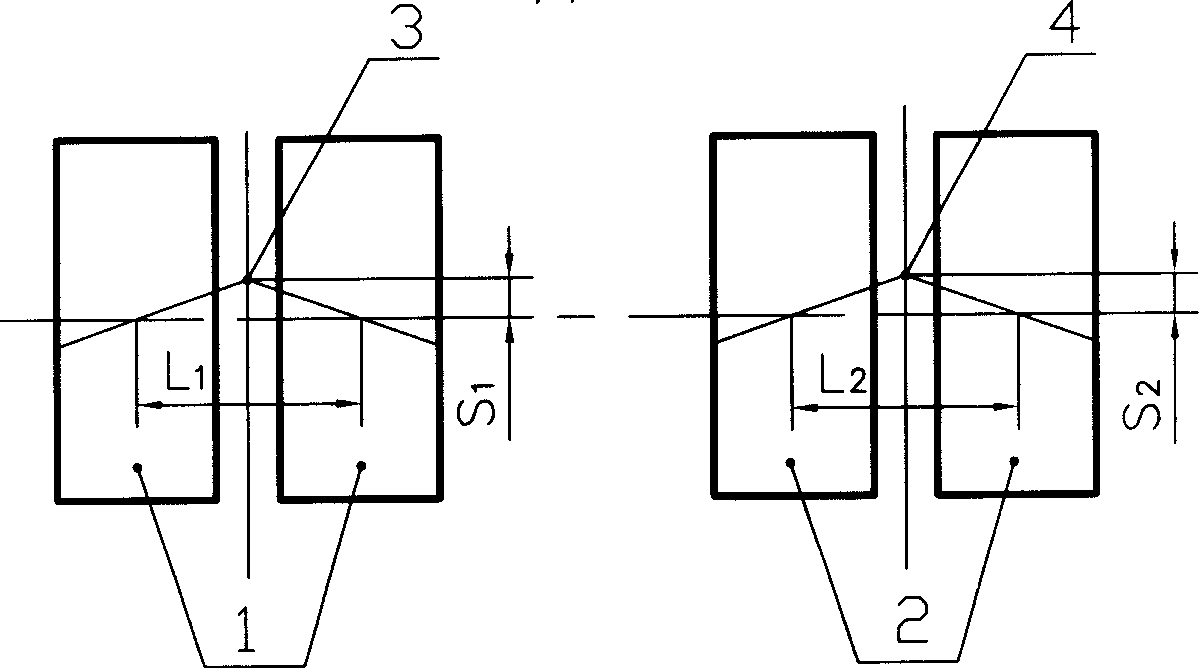

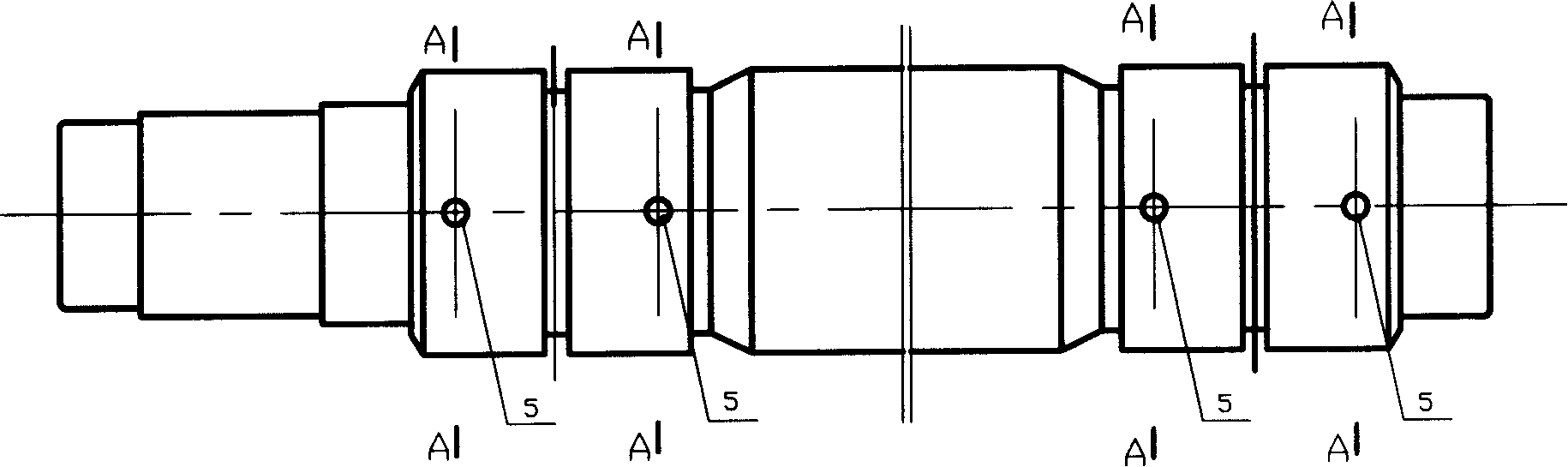

[0019] see Figure 1-Figure 6 , the double herringbone gear shaft blank is clamped on a high-precision CNC milling and boring machine, two process pin holes (5) are drilled on the two addendum circles of the double herringbone gear (1), two Drill two process pin holes (5) on the addendum circle, and control the center distance of the pin holes (5) of the herringbone gear (1) to be equal to the center distance of the pin holes (5) of the herringbone gear (2); then, set the angle The Y-axis reference side of the paper is aligned with the left end face of the herringbone gear (1) left-handed gear, and the hypotenuse of the angle paper passes through the center of the gear (1) process pin hole (5) to draw the left-handed herringbone gear (1) Gear tool setting center line (3); align the Y-axis reference edge of the angle paper with the right end face of the right-handed gear of the herringbone gear (1), and make the beveled edge of the angle paper pass through the process pin hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com