High whiteness tourmaline negative ion powder and coating process

A technology of negative ion powder and tourmaline, which is applied in dyeing high molecular organic compound treatment, dyeing low molecular organic compound treatment, inorganic pigment treatment, etc., can solve the problems of deep tourmaline color and limited application, and achieve short production cycle, The process is simple and feasible, and the effect of zero by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

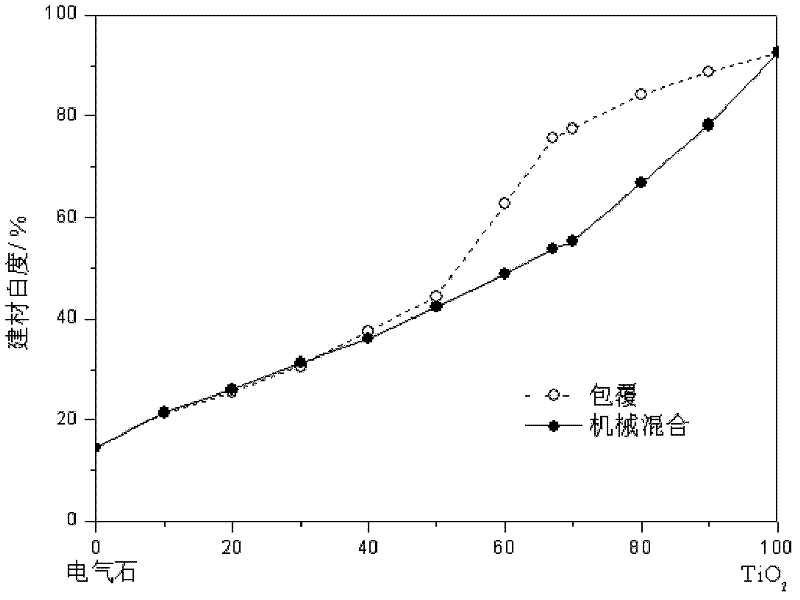

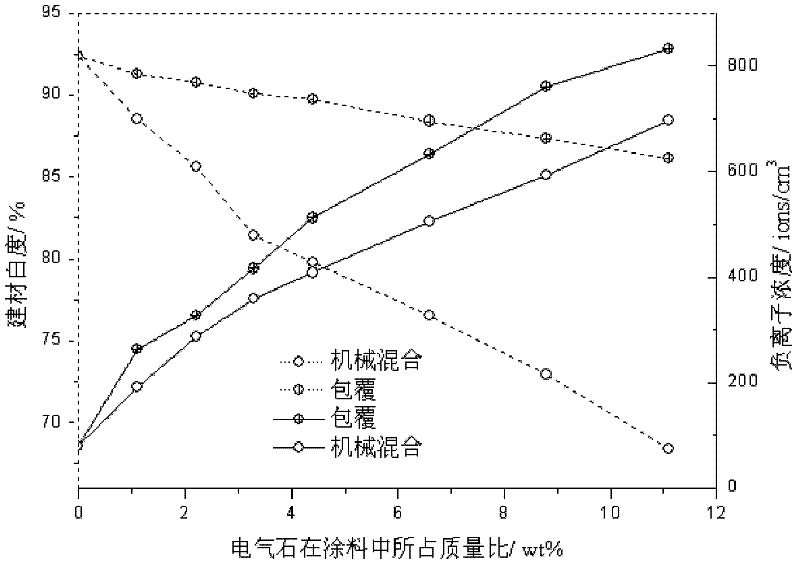

[0025] Provide below the embodiment of the present invention (see attached table), and provide corresponding measured data [1] :

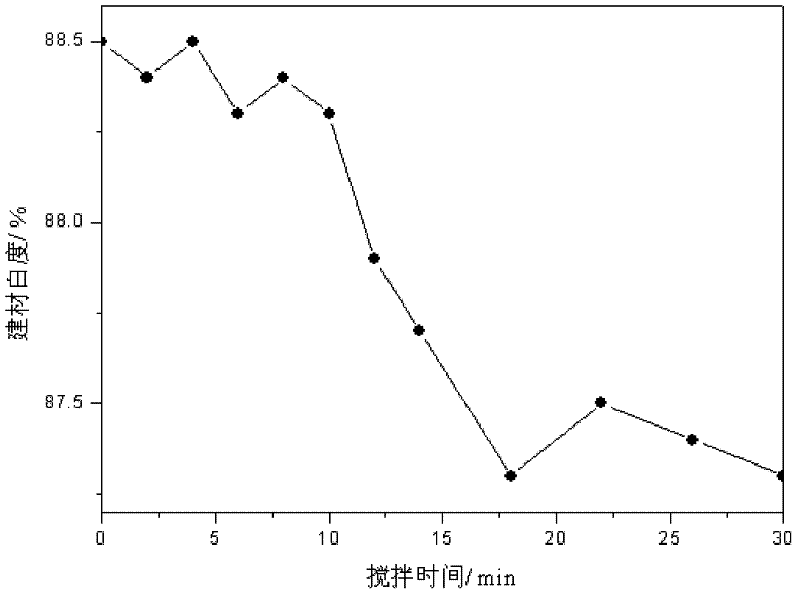

[0026] [1] Note in the table: In the examples, the particle size of the coating agent is ≤600nm. After the tourmaline ball mills to a particle size of 6-40μm, it is heat-treated in a muffle furnace at a calcination temperature of 300-750°C (1h of heat preservation); According to the requirement that the total weight of the prepared negative ion powder is 1.54Kg, the raw materials are weighed, the temperature of the cooling water in the cooling process is normal temperature, the stirring time in the subsequent stirring process is 3 to 6 minutes, and the particle size distribution of the obtained negative ion powder is D 97 =D 电气石 +1.75D 包覆剂 (error ±7%).

[0027] The particle size value indicated in [2] in the table is selected from D 97 .

[0028] [3] Coating strength test method in the table: After mixing the prepared negative ion powder with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com