Electric oven and oil fume odor purification device control method

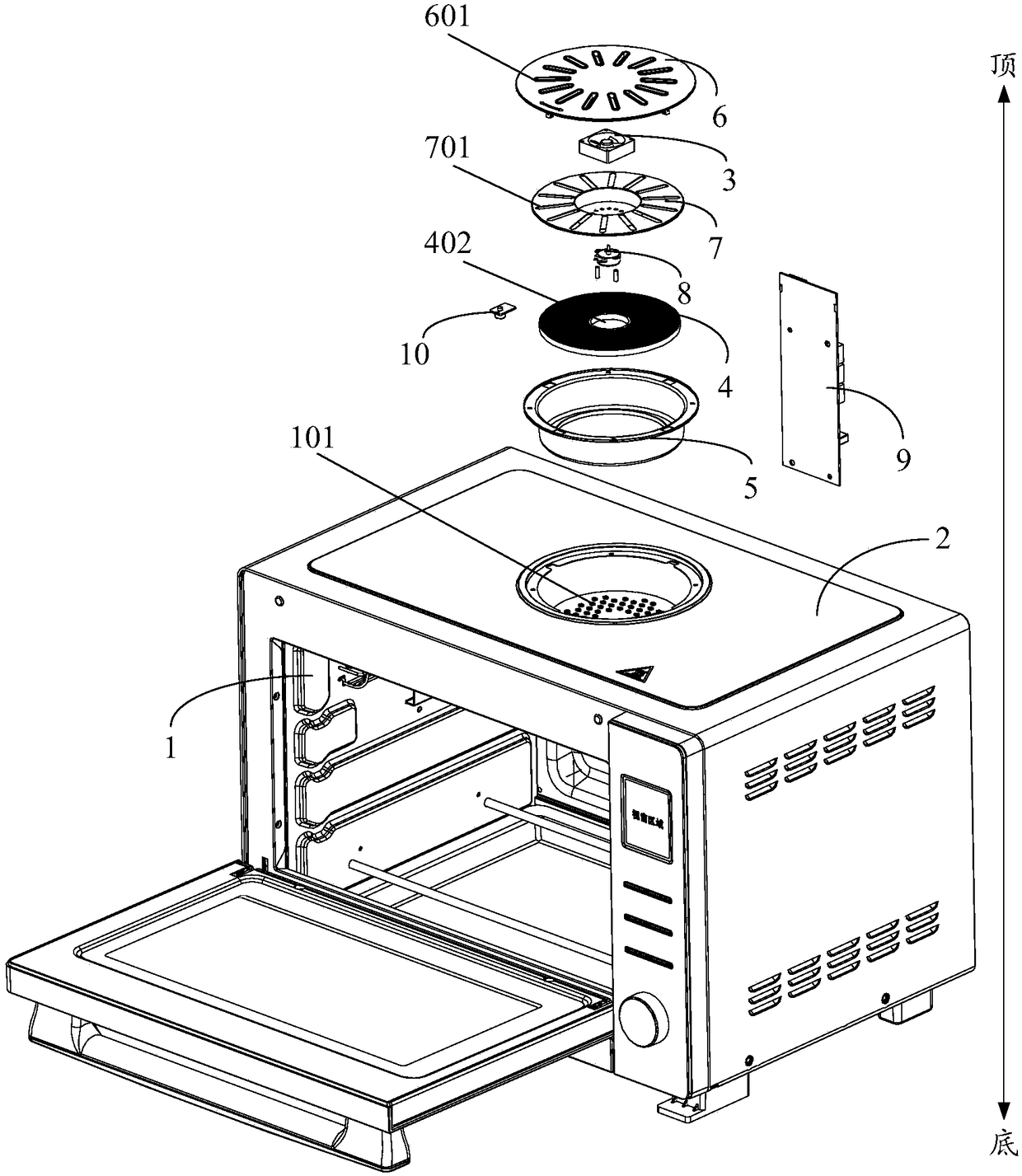

A purification device and control method technology, applied in the direction of oil fume removal, heating method, grill/barbecue grid, etc., can solve the problems of users' bad experience, affect user satisfaction with products, pollute indoor air, etc., and achieve structural Compact, takes up little space, and reduces power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Such as Figure 10 As shown, the control method of the cooking fume and odor purification device provided in this embodiment includes: step 102, detecting the concentration of cooking fume and peculiar smell through the smoke sensor; Concentration value; when the detection value of oil fume and peculiar smell concentration does not reach the preset starting concentration value, return to execute step 102, and the fan and motor do not work at this moment; when the detected value of oil fume and peculiar smell concentration reaches or exceeds the preset starting concentration value , execute step 106, the computer board controls the fan to continue to work, and controls the motor to rotate the motor shaft at a certain angle to drive the inner cover to move to open the first air outlet; step 108, when the heating time of the electric oven reaches the preset time, the computer The board controls the blower to stop, and controls the motor to rotate the motor shaft at a certa...

Embodiment 2

[0088] Such as Figure 11 As shown, the control method of the cooking fume and odor purification device provided in this embodiment includes: Step 202, detecting the concentration of cooking fume and peculiar smell through the smoke sensor; Concentration value; when the detection value of oil fume and peculiar smell concentration does not reach the preset starting concentration value, return to execute step 202, and the fan and motor do not work at this time; when the detected value of oil fume and peculiar smell concentration reaches or exceeds the preset starting concentration value , execute step 206, the computer board controls the fan to continue to work, and controls the motor to rotate the motor shaft at a certain angle to drive the inner cover to move to open the first air outlet; step 208, continue to detect the concentration of oily smoke and odor through the smoke sensor; step 210 , judging by the computer board whether the detection value of the oil fume and odor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com