Method of preparing large non crystal/fiber composite material and tis equipment

A technology of fiber composite materials and amorphous alloys, applied in the field of vacuum infiltration casting, can solve the problems of large size of fiber reinforced amorphous alloy composite materials, restricting the application range of materials engineering, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

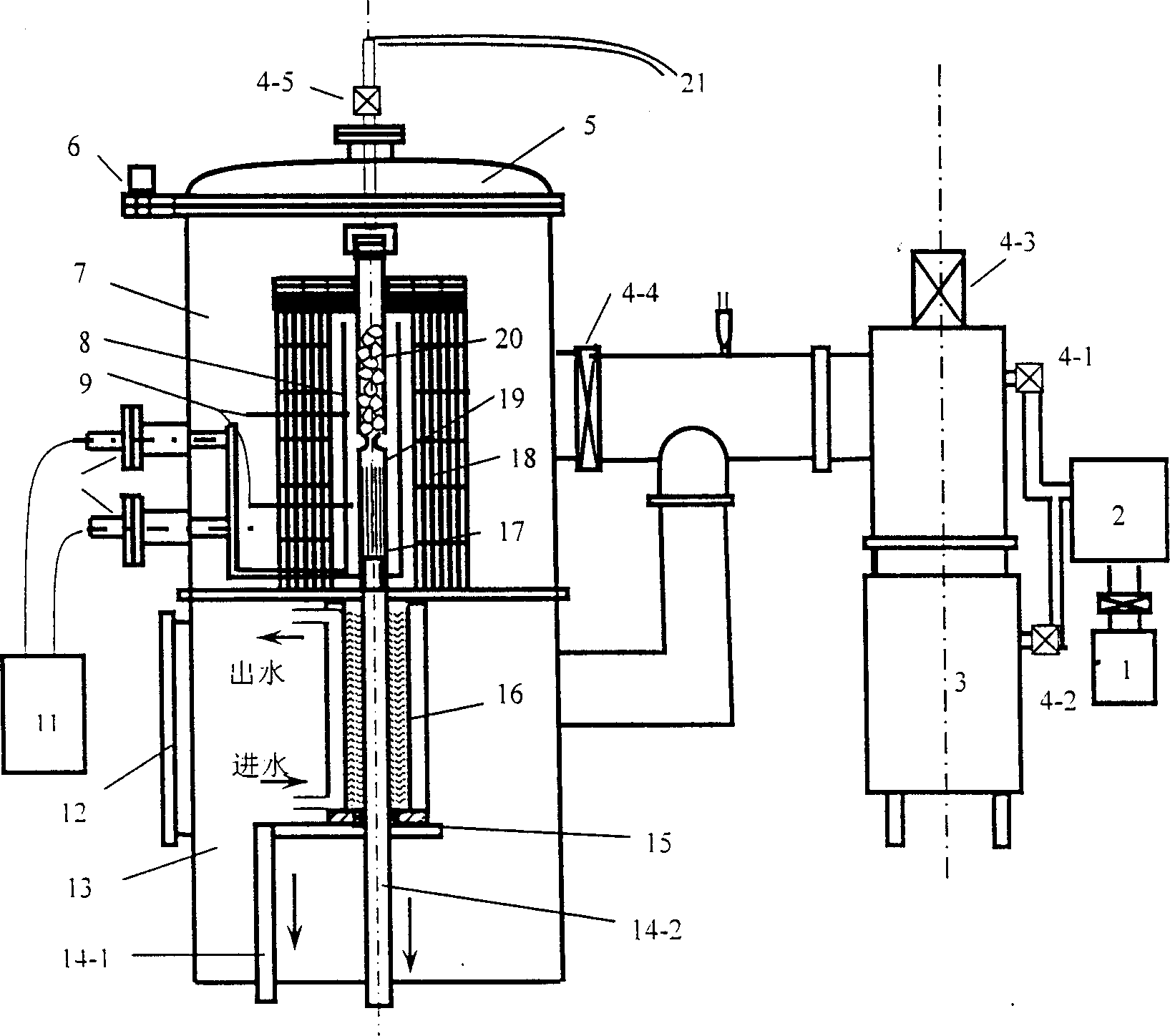

Method used

Image

Examples

Embodiment Construction

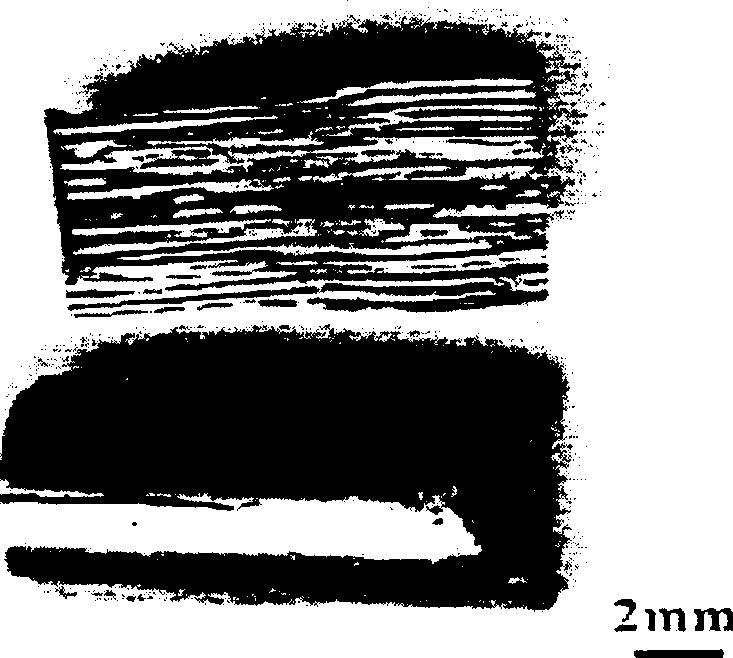

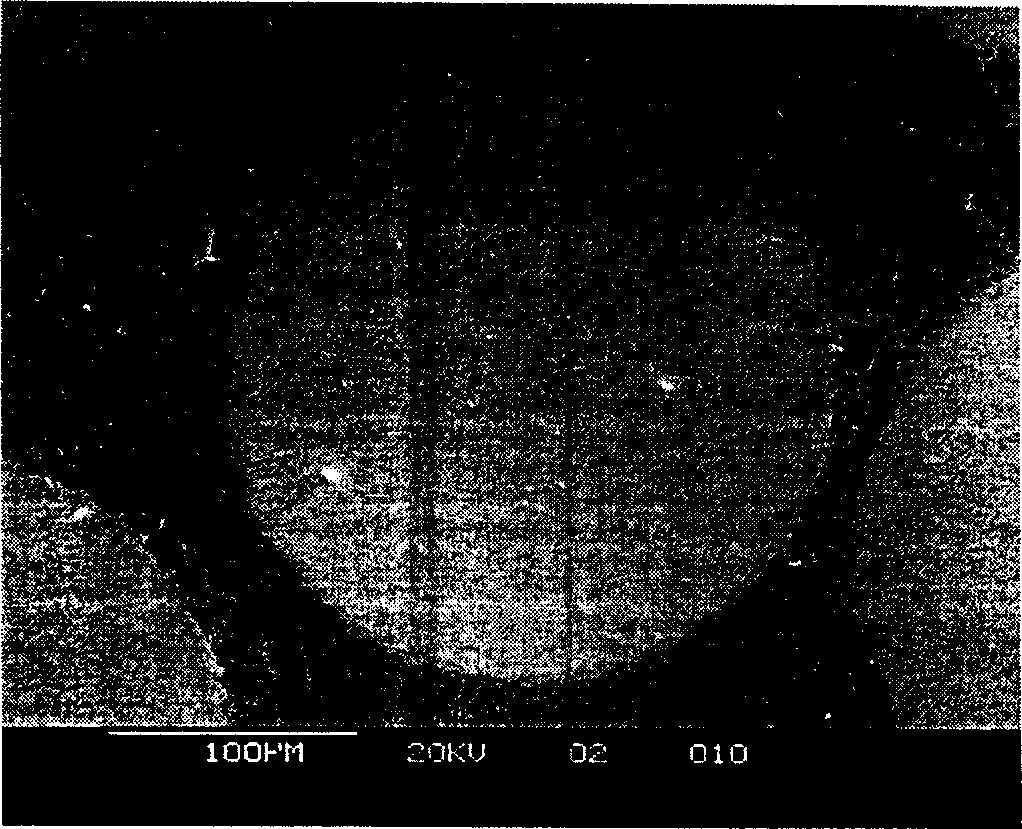

[0015] Five high-purity pure metals are selected, namely Zr (99.99wt%), Ni (99.95wt%), Cu (99.95wt%), Al (99.95wt%), Nb (99.99wt%). According to the atomic percentage: Zr is 57, Cu is 15.4, Ni is 12.6, Al is 10, and Nb is 5. Under the protection of high-purity argon with a purity of 99.8%, the purification technology of the liquid master alloy is applied, and the electric arc is used. The master alloy is obtained by melting. In order to ensure the homogeneity of each component in the master alloy, the master alloy was remelted three times. The surface of the master alloy ingot is mechanically ground and polished to remove surface oxide scale, then crushed into small pieces and the surface is cleaned with alcohol. Straighten the tungsten fiber with a diameter of 250μm and cut it into a length of 100mm. In order to ensure a good distribution of the tungsten fiber and avoid uneven density, the tungsten wire should be properly bent. First clean the oxide layer on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com