Method for casting polycrystalline silicon ingot based on quasi-single crystal semi-melting technology

A polycrystalline silicon ingot, quasi-single crystal technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of less single feeding, short life, complicated operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

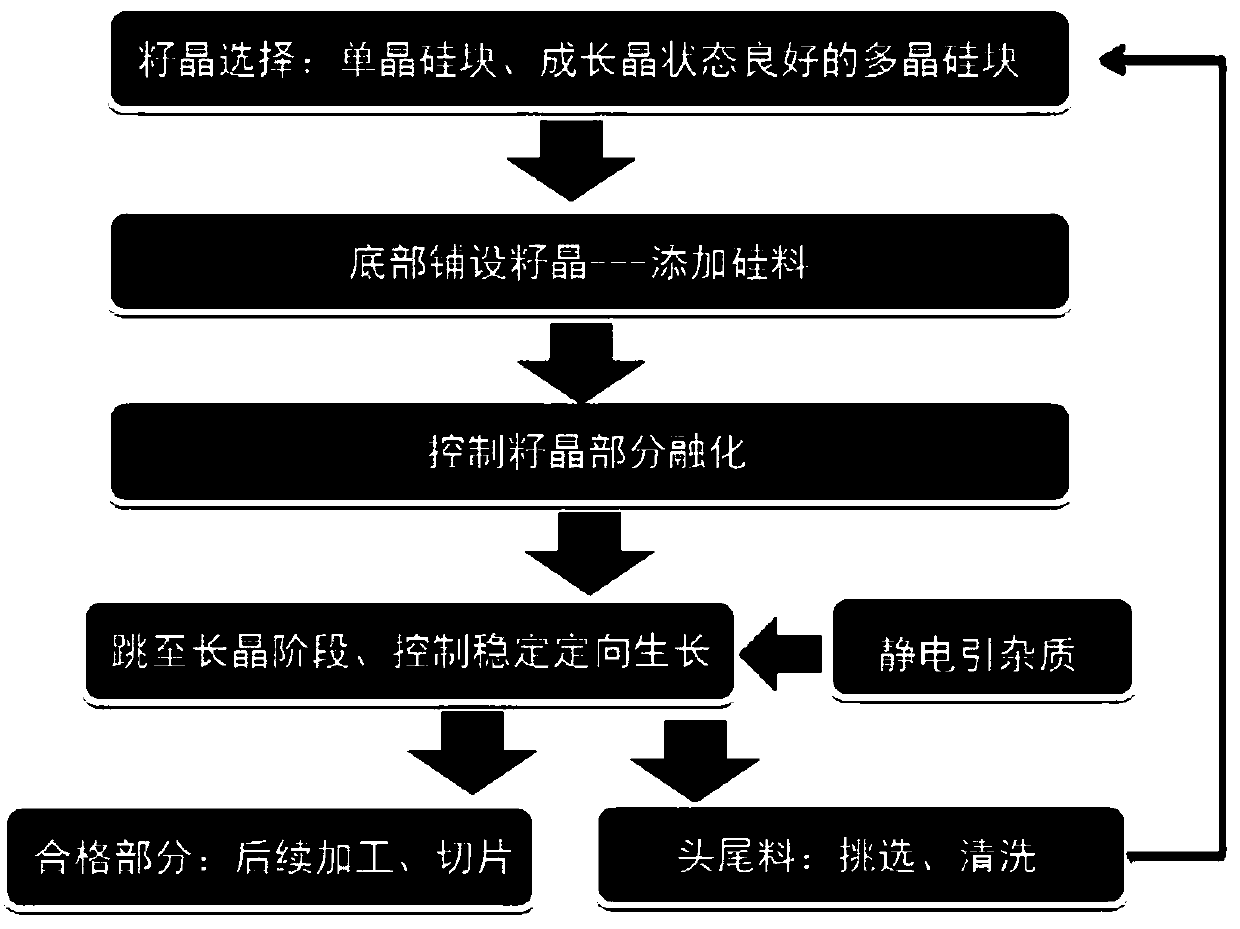

[0041] The method for casting polycrystalline silicon ingots based on quasi-single crystal semi-melting technology of the present invention uses the principle of single crystal production to carry out polycrystalline ingot casting, and takes the millimeter-scale seed crystal as the nucleation center to perform outer edge growth seeding, on the same cross section Alleviate the dislocation proliferation, subgrain boundary and self-interstitial atoms caused by the large thermal stress at the edge of the silicon ingot, reduce the length of the red area at the bottom, and improve the electrical conductivity of polysilicon.

[0042] Such as figure 2 Shown, the method for casting polycrystalline silicon ingot based on quasi-single crystal semi-melting technology of the present invention, it comprises the following technical contents:

[0043] Step 1 Seed selection

[0044] Choose monocrystalline silicon blocks and polycrystalline silicon blocks with good growth conditions.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com