Novel glass fibre composition

A technology of glass fiber and composition, applied in the field of glass fiber composition, which can solve the problems of high raw material cost, lower molding temperature and liquidus temperature, and high molding temperature of glass fiber composition, so as to improve mechanical strength and chemical stability properties, low molding temperature and liquidus temperature, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

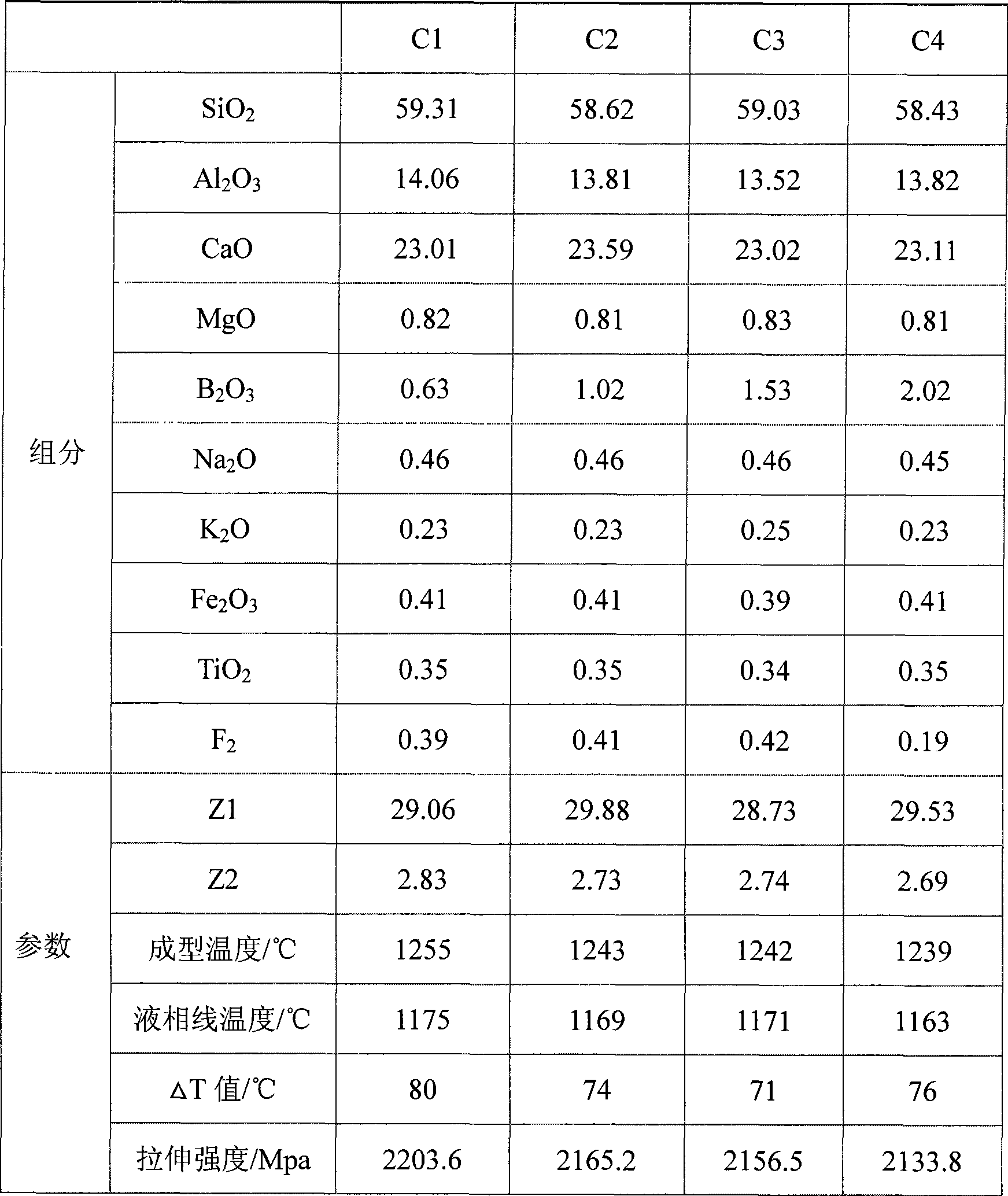

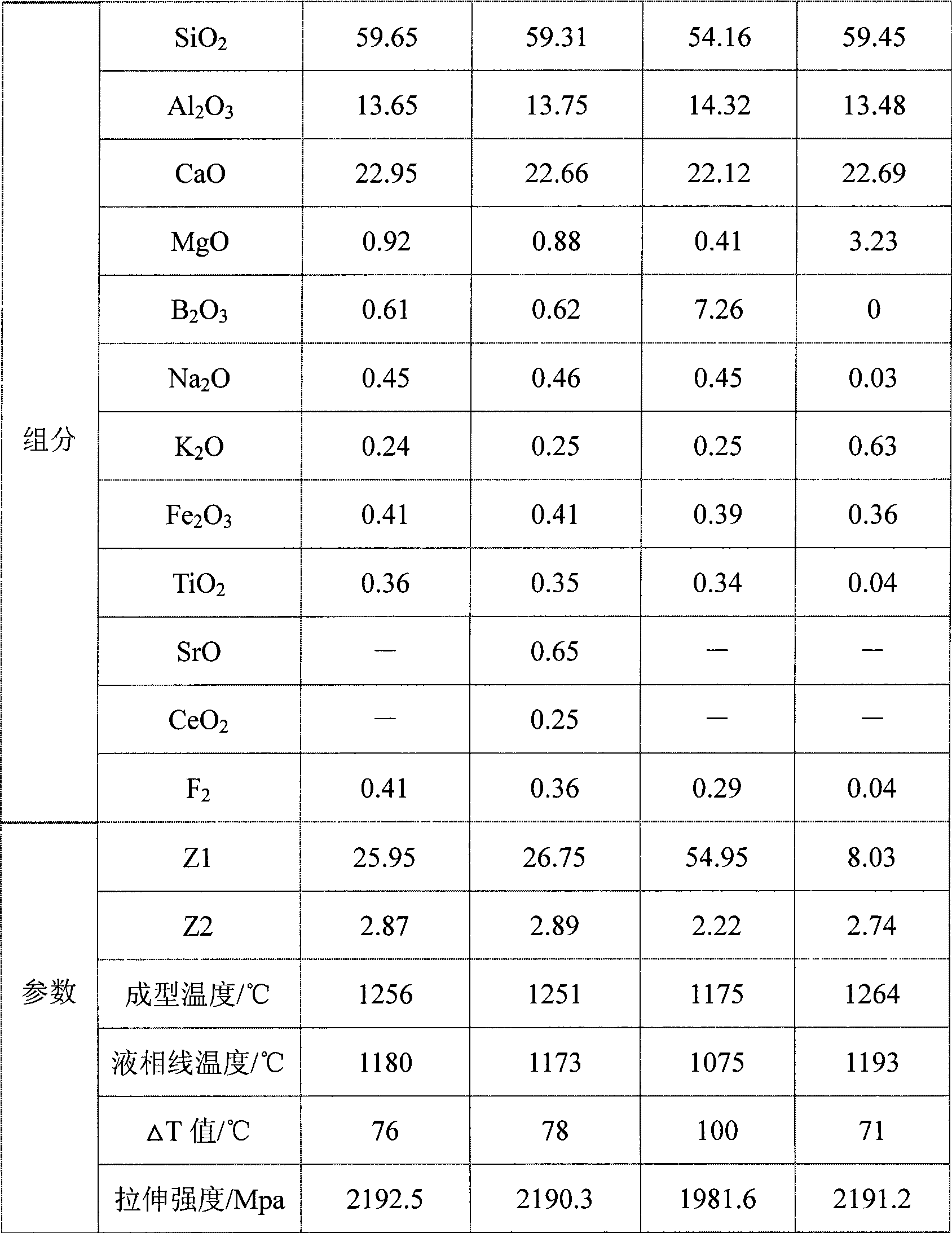

[0088] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples.

[0089] In the examples of the present invention, for the convenience of operation, the total content of the glass fiber composition is 100%, and the total content of the components in the examples is slightly less than 100%. It can be understood that the residual amount is a small amount of impurities or a small amount of components that cannot be analyzed .

[0090] The main raw materials for producing glass fiber in the present invention are pyrophyllite, quartz powder, limestone, dolomite, boronite and the like. The concrete process of the embodiment of the present invention is as follows: each composition can obtain from suitable raw material (as SiO in quartz powder 2 , CaO in quicklime), mix the various raw materials in an appropriate proportion, so that each compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com