Patents

Literature

35results about How to "Optimizing the drawing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

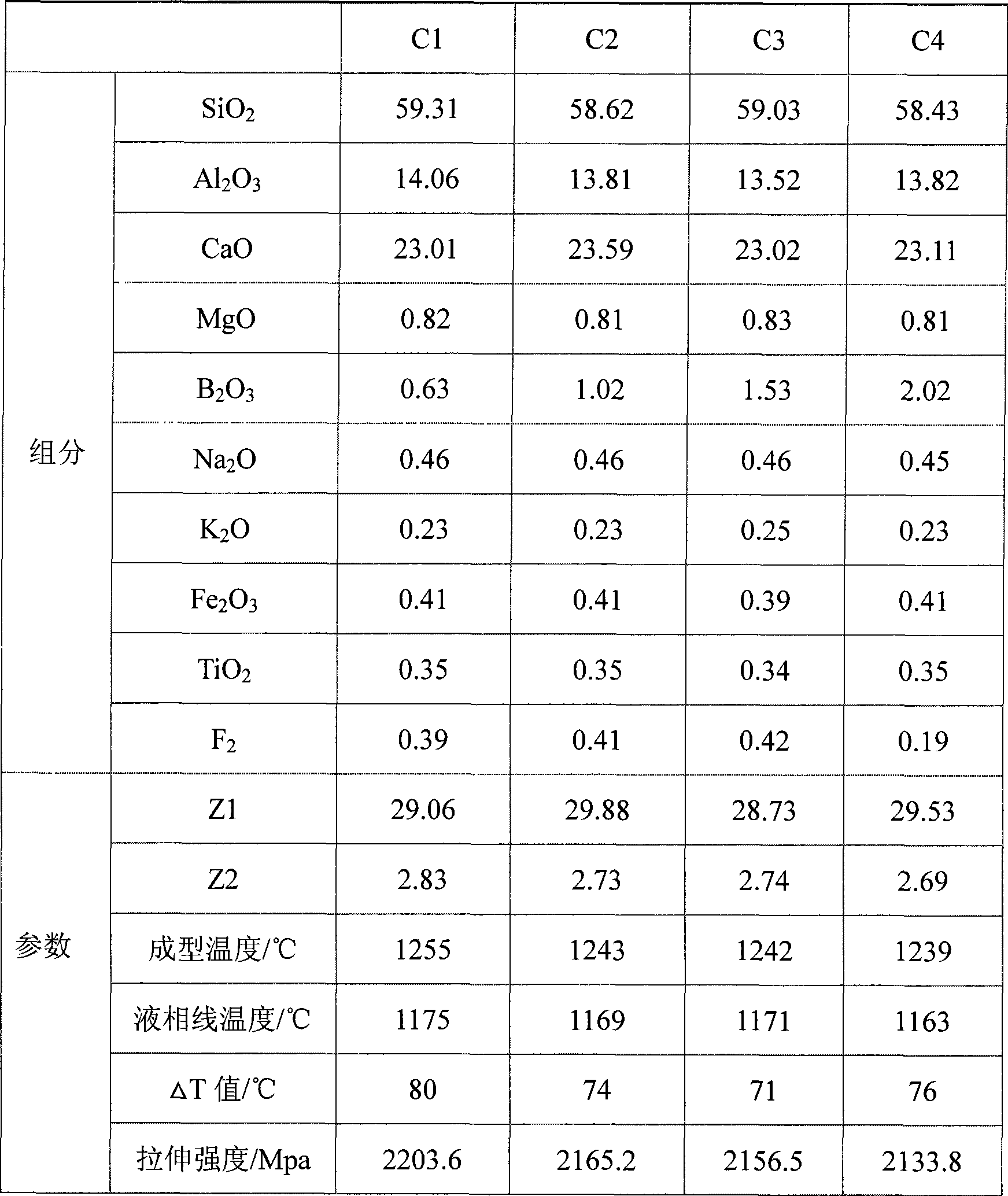

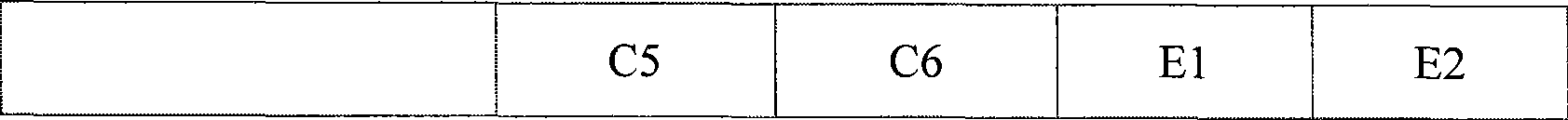

Novel glass fibre composition

The invention relates to a glass fiber composition. The composition comprises the following compositions in percentage by weight: 58 to 65 percent of SiO2, 20 TO 26 percent of CaO, 9 to 17 percent of Al2O3, 0.5 to 1 percent of MgO, 0 to 5 percent of B2O3, 0 to 1 percent of F2, 0.1 to 1 percent of TiO2, 0 to 0.8 percent of K2O and Na2O, 0.1 to 0.5 percent of Fe2O3, and 0 to 0.6 percent of SO3. The glass fiber composition uses SiO2-Al2O3-CaO three-element system as basis, introduces MgO and B2O3 with low content, and reasonably designs the gross weight of alkaline metal oxides and the proportional relationship between the MgO and the CaO, not only contributes to the improvement of the mechanical strength, the high temperature resistance and the chemical stability of the glass, but also has excellent drawing performance; furthermore, the glass fiber composition has low cost in raw materials, and meets the requirement of environmental protection.

Owner:JUSHI GRP CO

Preparation method of high-resistance electrothermal alloy wire

InactiveCN104630564AEasy to organizeImprove plasticityFurnace typesHeat treatment process controlElectrical resistance and conductanceNickel chromium alloy

The invention discloses a preparation method of a high-resistance electrothermal alloy wire, and relates to the iron chromium aluminum alloy processing and manufacturing field. The preparation method includes five technological processes of blank preparation, annealing treatment, alkali washing, cleaning and wiredrawing treatment; in the annealing treatment process in the preparation method, through strict control of the heating temperature and the holding time of a box type resistance furnace, the internal organization of a nickel-chromium alloy wire is improved, the plasticity is increased, and the subsequent drawing technology is facilitated; in the alkali washing process, through well control of the temperature and time of alkali washing, an oxidation film of the surface of the nickel-chromium alloy wire is removed relatively thoroughly, the impurity residual amount is precious little, and the surface is smooth; and the nickel-chromium alloy wire prepared by the preparation method has high-temperature oxidation resistance greatly improved, has the advantages of high electrical resistivity, high mechanical strength under high temperature conditions, long service life, simple production process, and easy realized automation production.

Owner:DANYANG ZHISHENG ALLOY

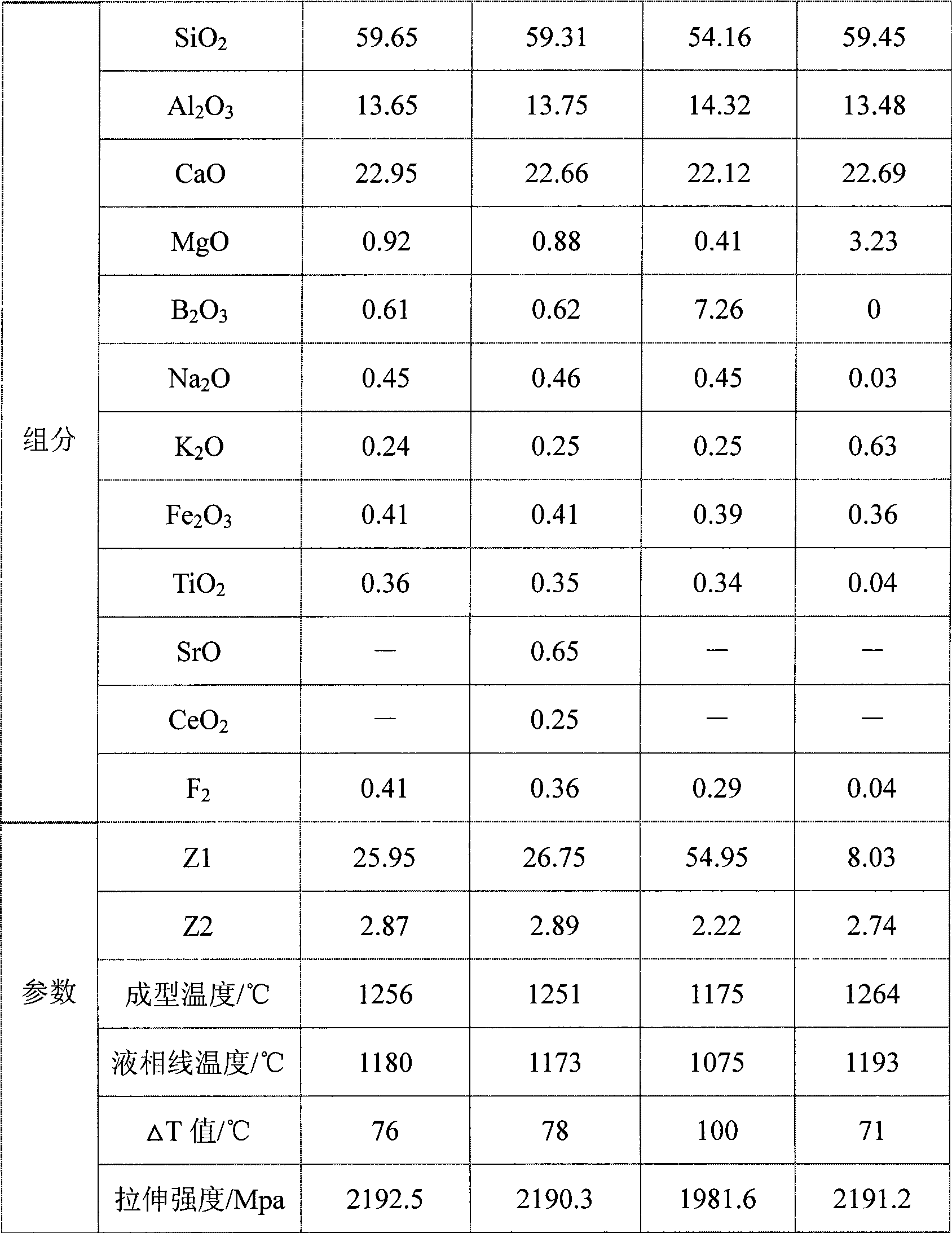

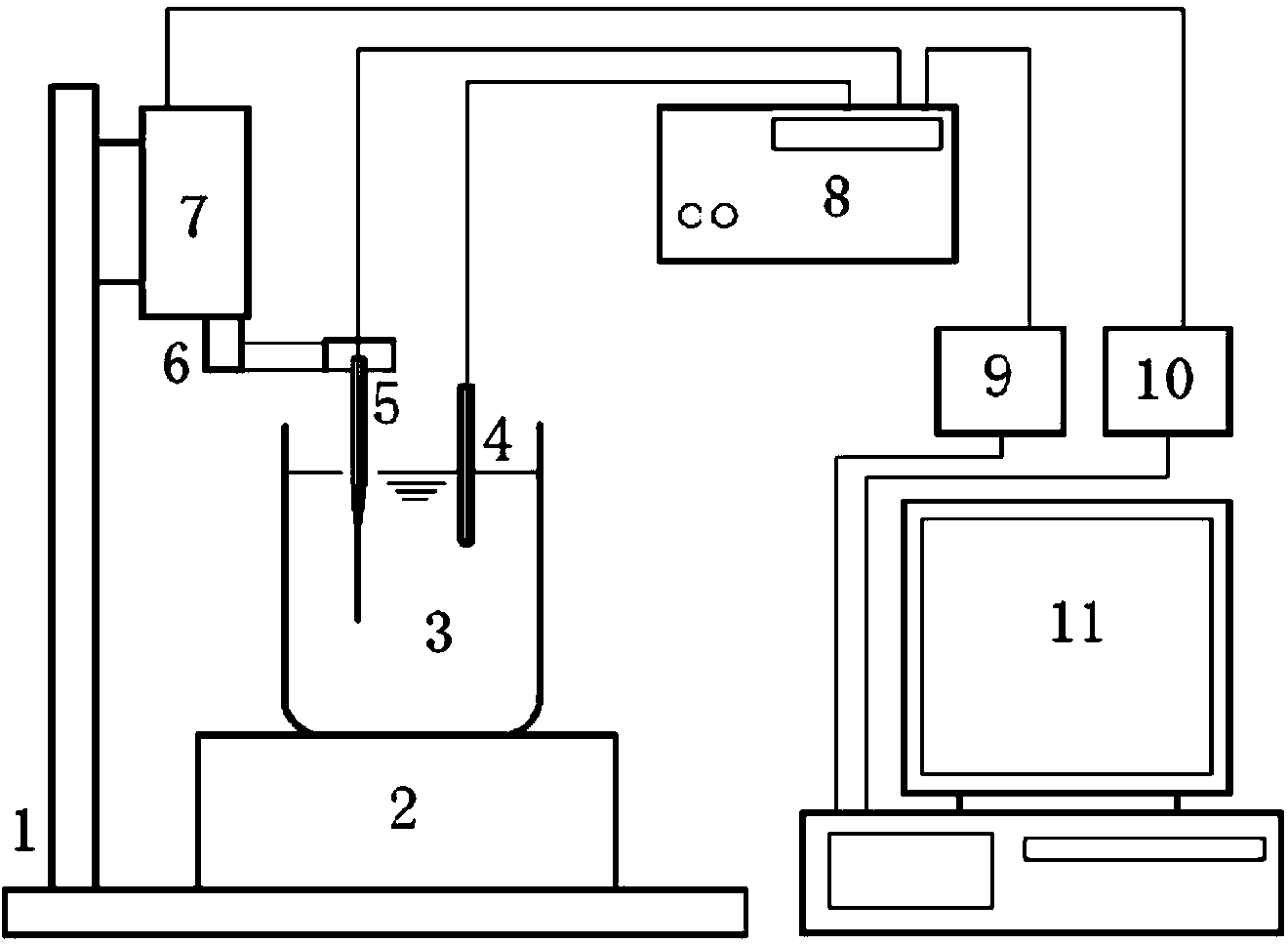

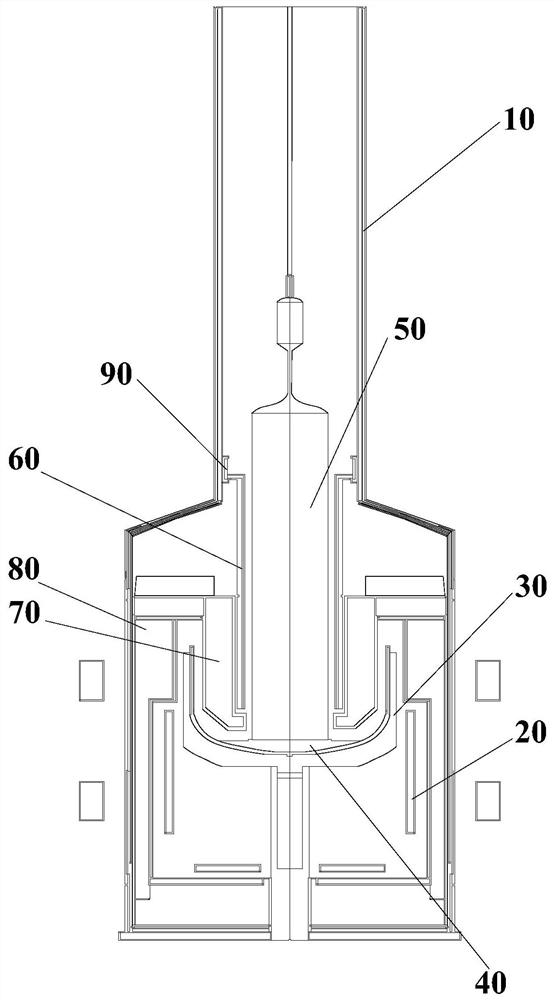

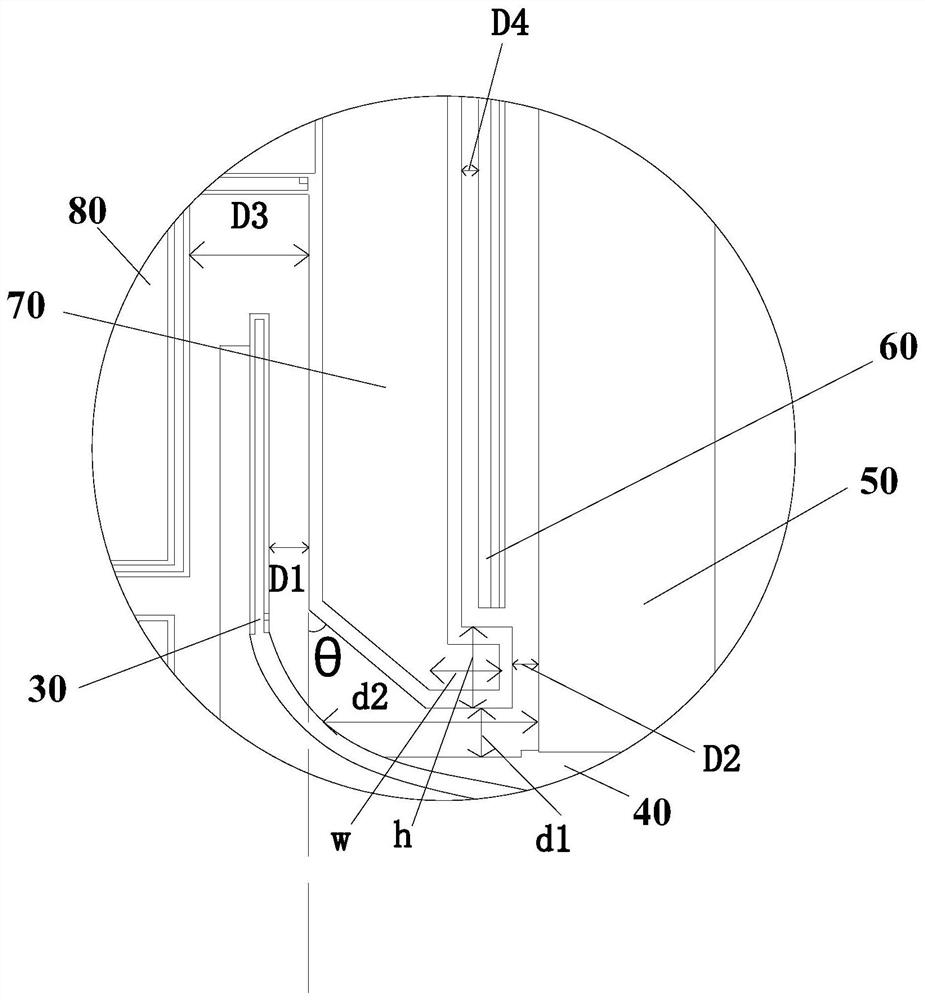

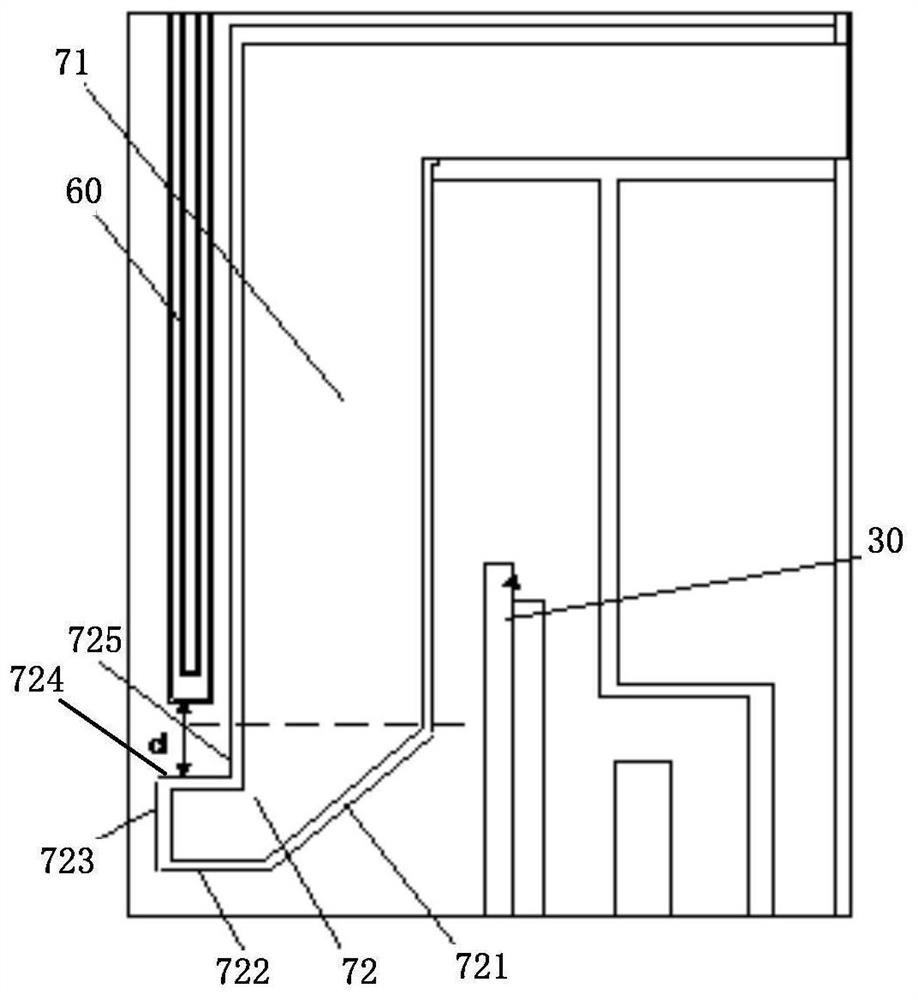

Crystal growth apparatus and crystal growth method

ActiveCN112281210AOptimizing the drawing processDrawing solutionBy pulling from meltCruciblePhysical chemistry

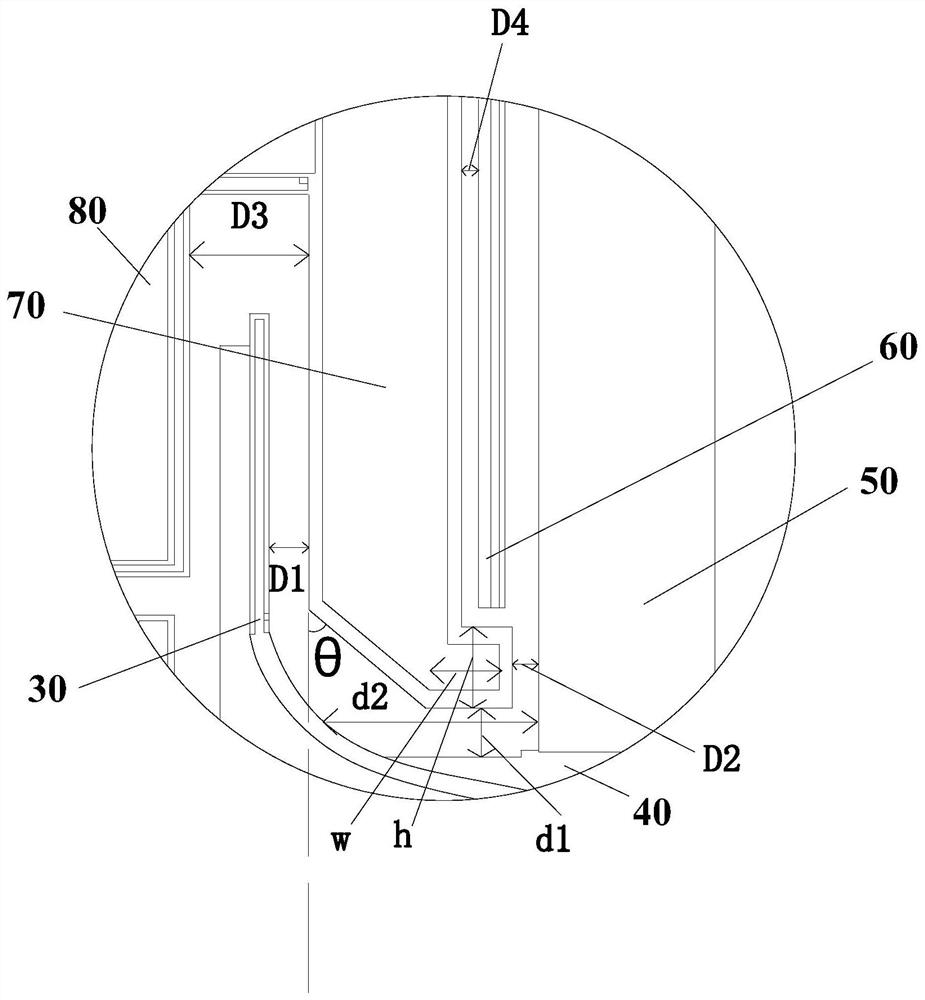

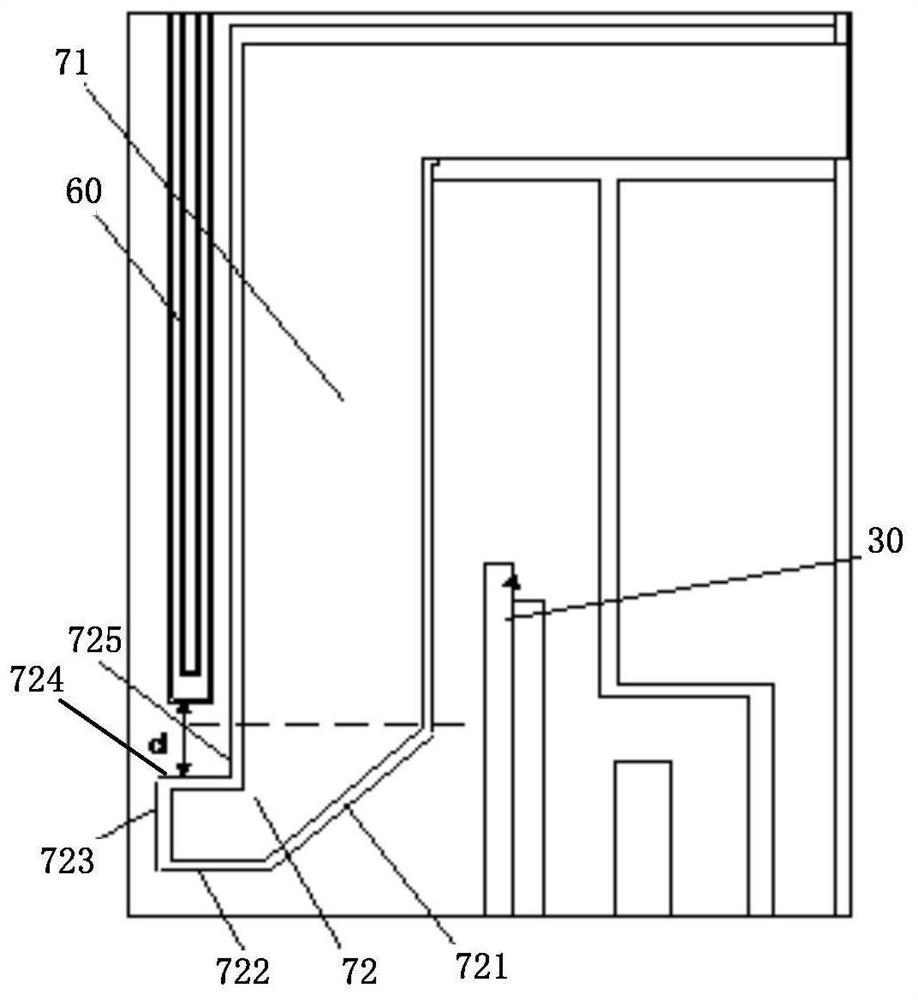

The invention provides a crystal growth apparatus and a crystal growth method. The crystal growth apparatus comprises a furnace body, a crucible, a cooling sleeve and a guide cylinder, wherein the cooling sleeve is arranged in the furnace body and cools a crystal; the guide cylinder is arranged on the periphery of the cooling sleeve; the guide cylinder comprises an upper guide cylinder part and alower guide cylinder part, the upper guide cylinder part is cylindrical and surrounds the cooling sleeve, the lower guide cylinder part is arranged at the lower end of the upper guide cylinder part and located on the lower side of the cooling sleeve, the lower guide cylinder part is of a hollow big-end-up circular truncated cone structure, a groove is formed in the inner circumferential wall of the circular truncated cone structure, and the top of the groove penetrates through the circular truncated cone structure;and the cooling sleeve moves in the axial direction of the crucible. In the growth apparatus, the cooling sleeve moves along the axial direction of the crucible to influence thermal field distribution in the furnace body, and the temperature gradient at a solid-liquid interface can be finely adjusted, so crystals with a certain width and no defect growth area can be drawn, and the problem that the crystals with considerable defects in the growth area are drawn due to the factthat the temperature gradient of the solid-liquid interface is difficult to control in the prior art is solved.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

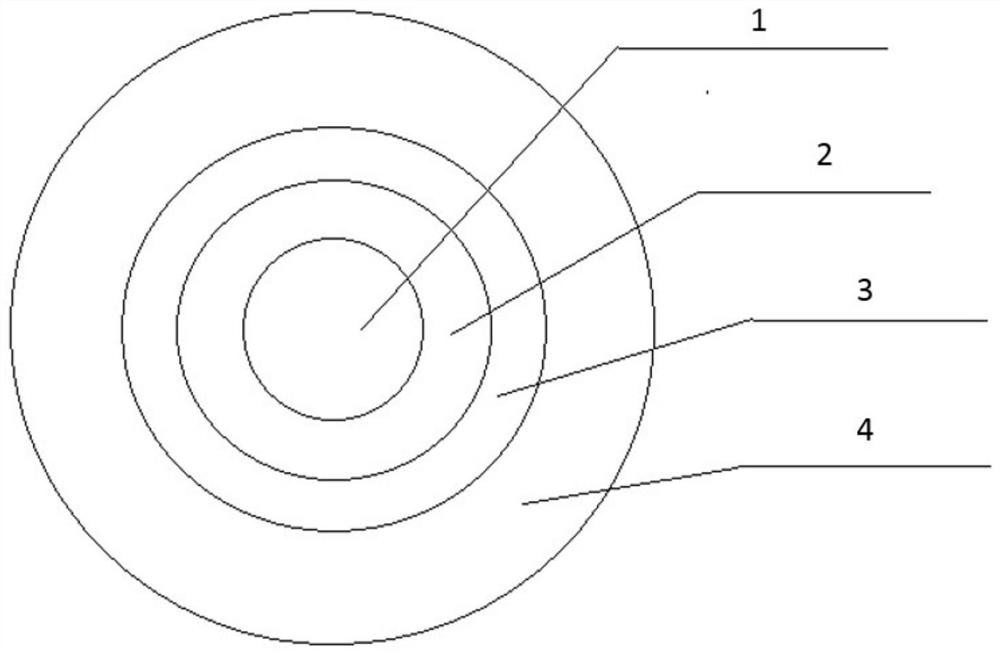

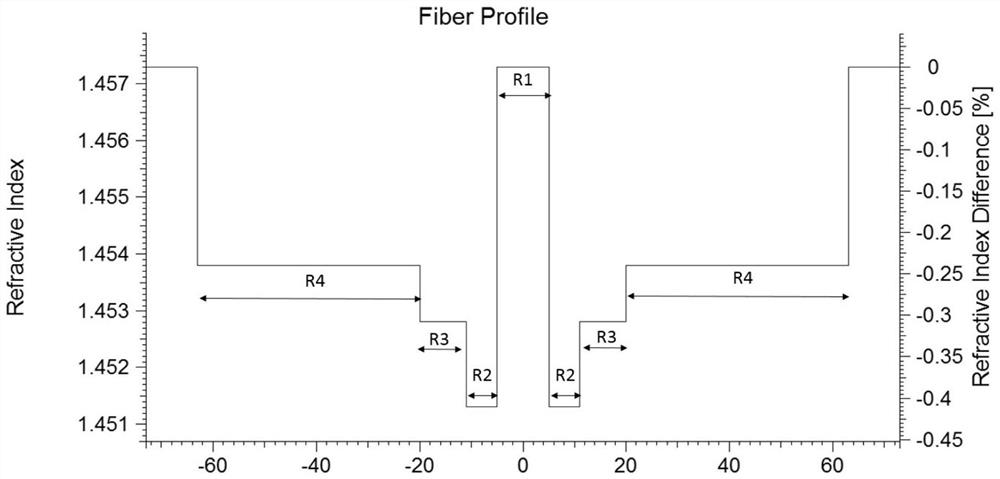

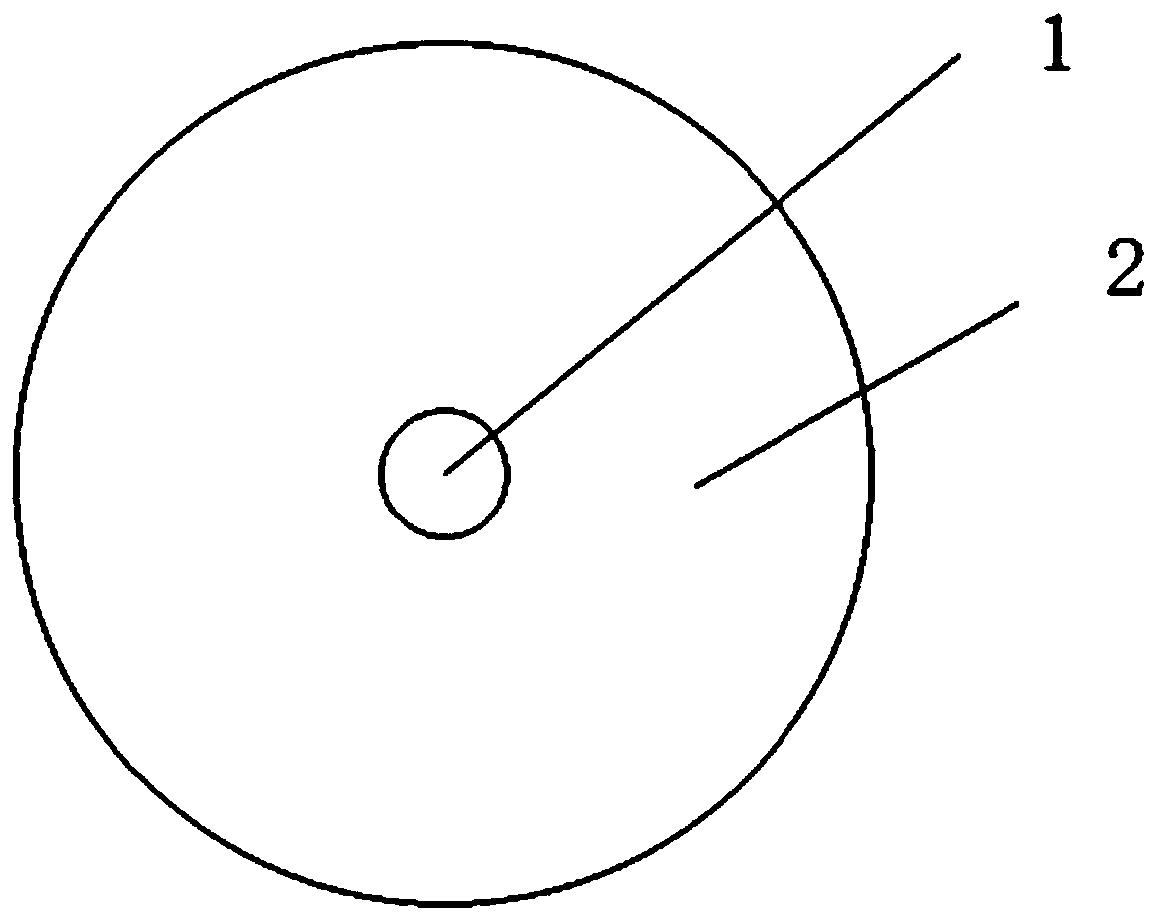

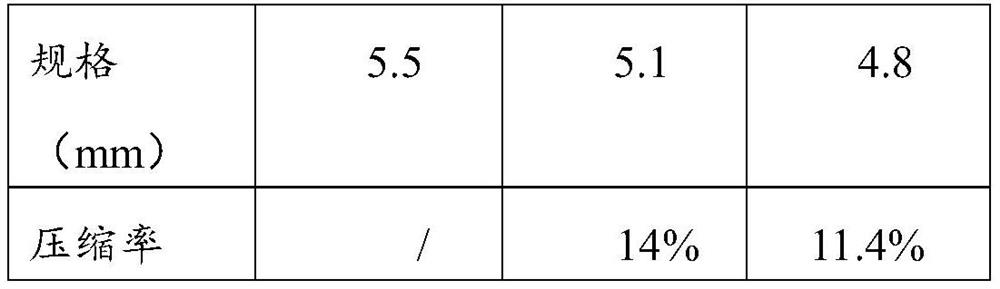

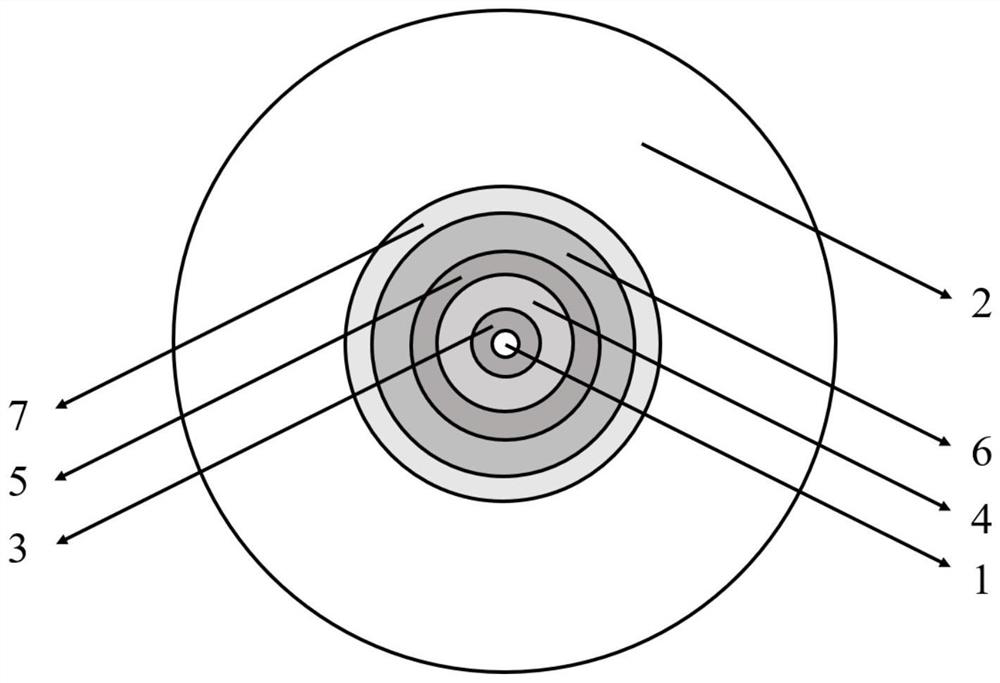

Multi-core fiber with low crosstalk between cores

PendingCN109283613ALow crosstalk between coresLarge mode field areaMulticore optical fibreOptical waveguide light guideMultiplexingTransport system

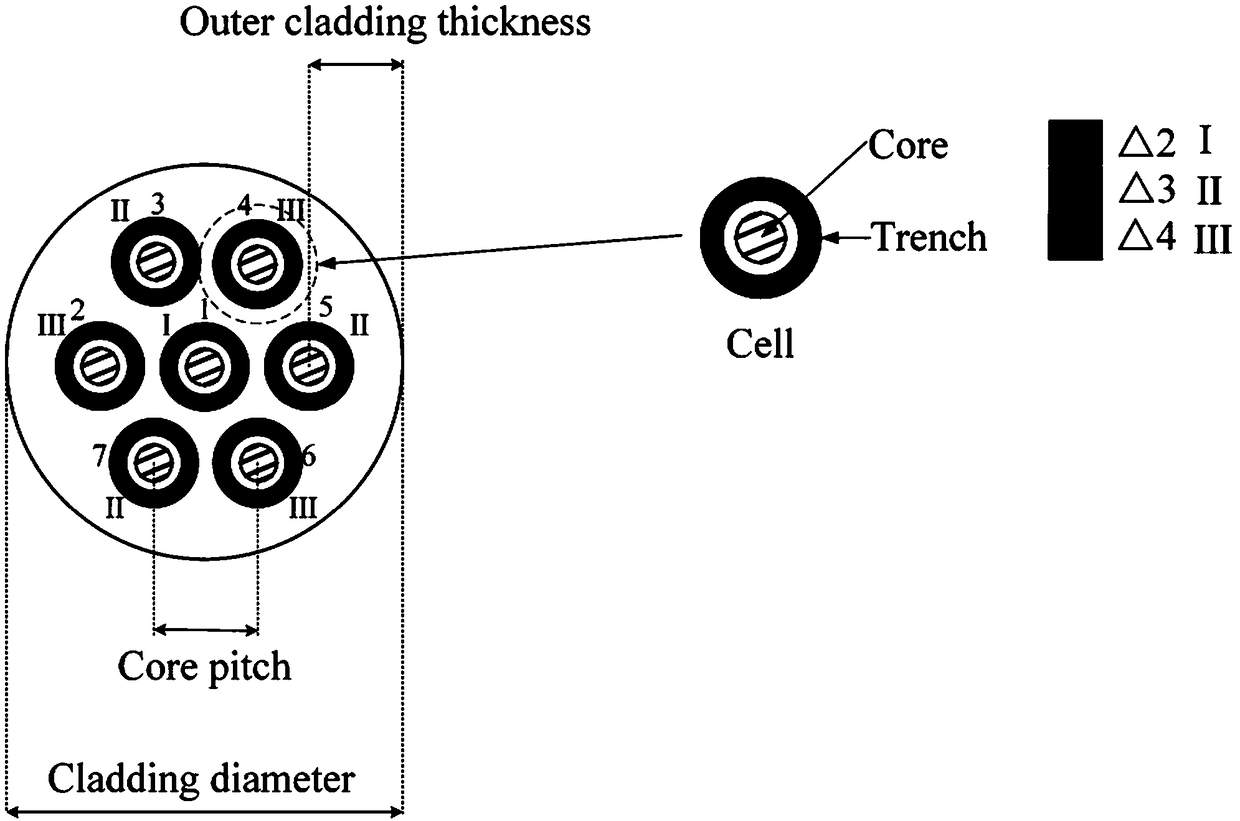

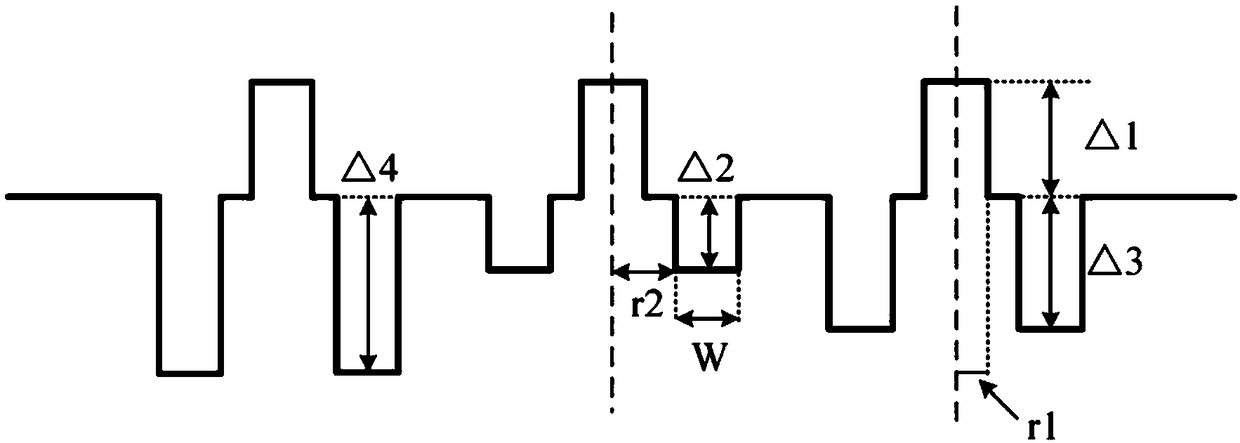

The invention relates to a multi-core fiber with low crosstalk between cores, and belongs to the field of optical fiber communication. The multi-core fiber with low crosstalk between the cores is characterized by comprising a middle core (1), an annular groove structure (I) around the periphery of the middle core, six outer cores (2)-(7) extending along the fiber axis and arranged in a regular hexagon shape, annular groove structures (II) and annular groove structures (III) around the peripheries of the six outer cores correspondingly, and wrapping layers covering the middle core, the six outer cores and the groove structures (I), (II) and (III). Different refractive indexes are arranged in the adjacent groove structures (I), (II) and (III) correspondingly, and the refractive index difference among the adjacent groove structures (I) and (II), (II) and (III) is no less than 0.001, and thus the purpose of suppressing crosstalk between the cores is achieved. Meanwhile, since the core structures are the same, the multi-core fiber with low crosstalk between the cores has smaller melting loss than ordinary single mode fibers, is facilitated to being drawn into the fiber, can be widely applied to air-division multiplexing optical fiber transmission system and other fields, and has broad application prospects.

Owner:BEIJING JIAOTONG UNIV

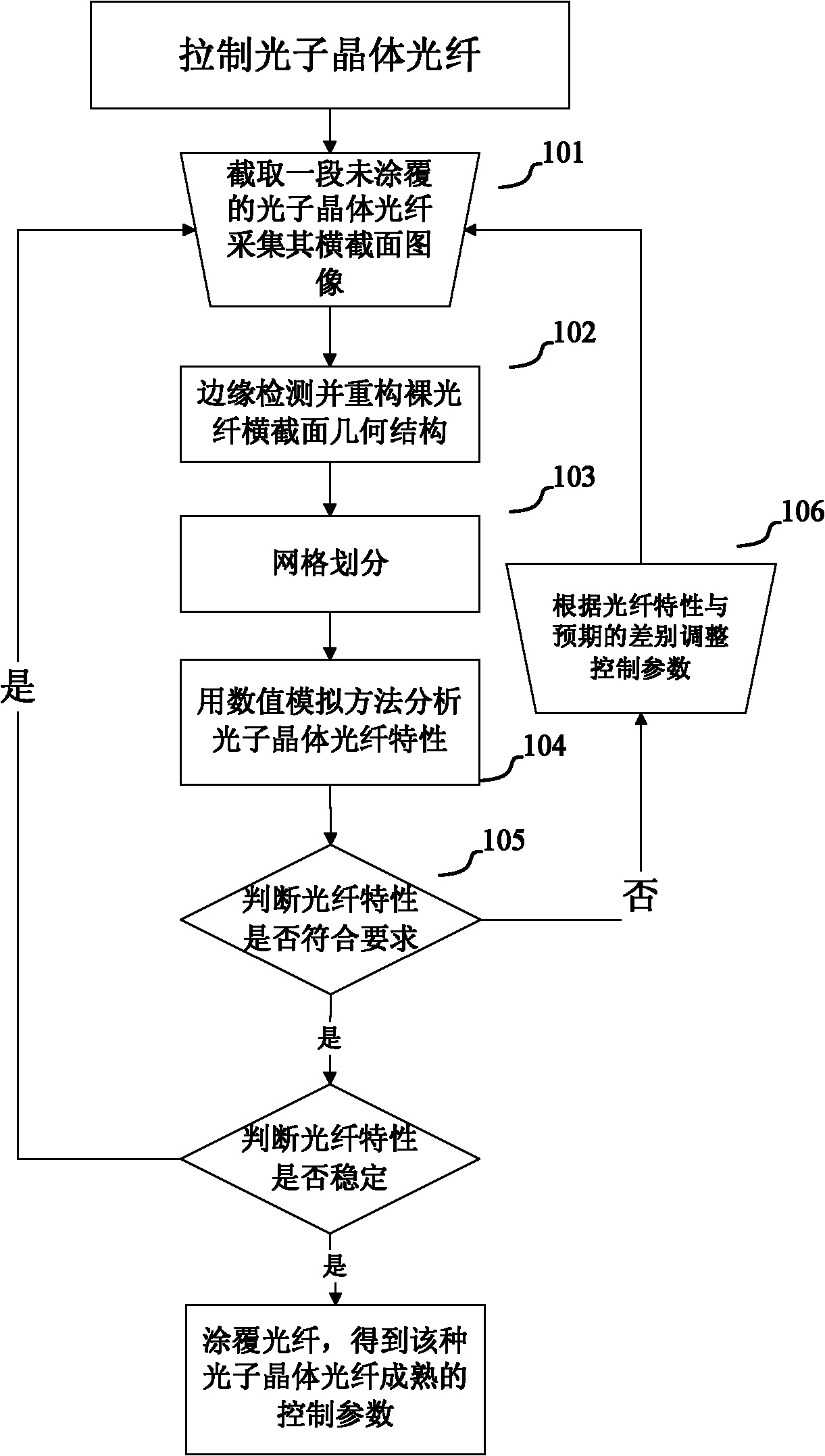

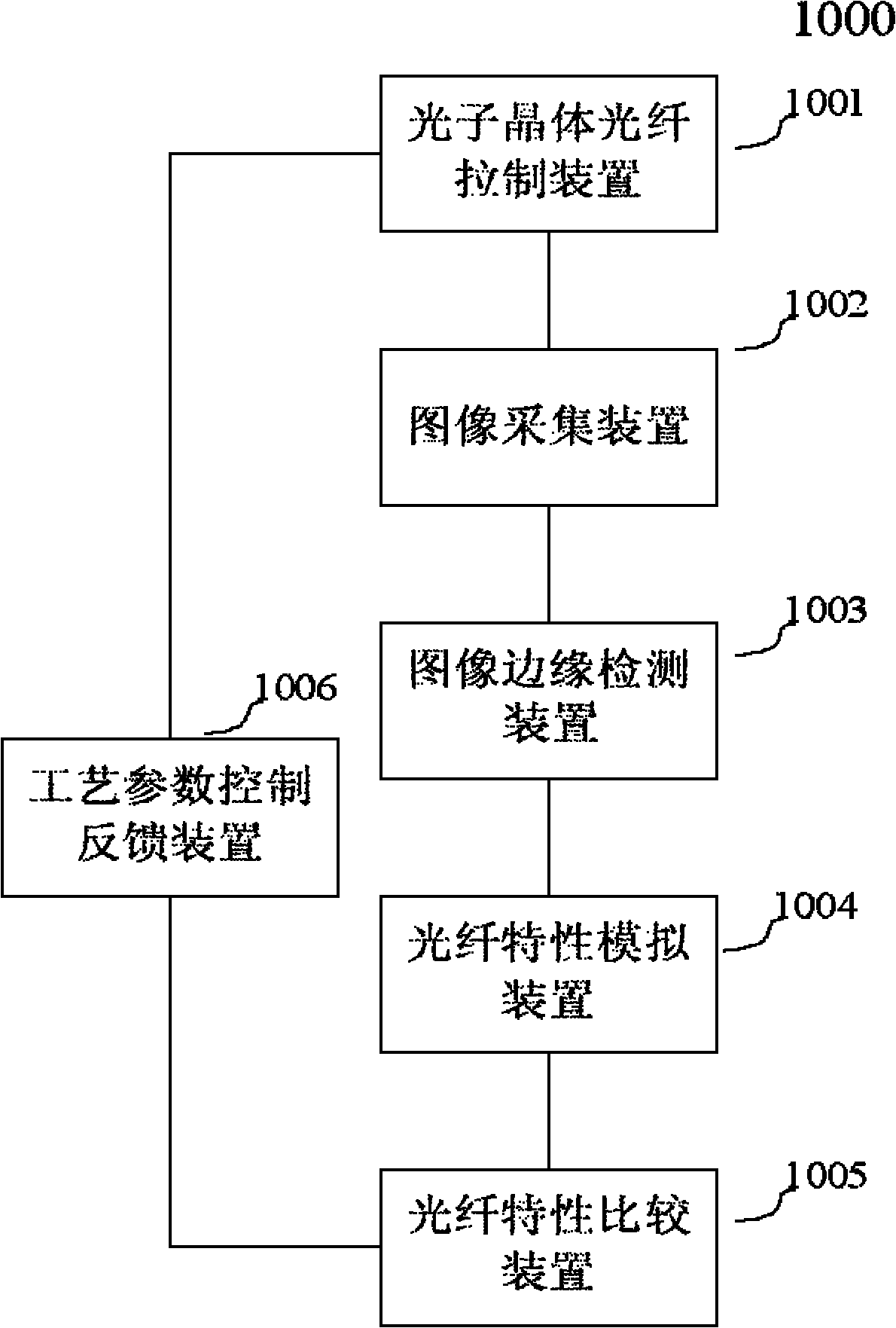

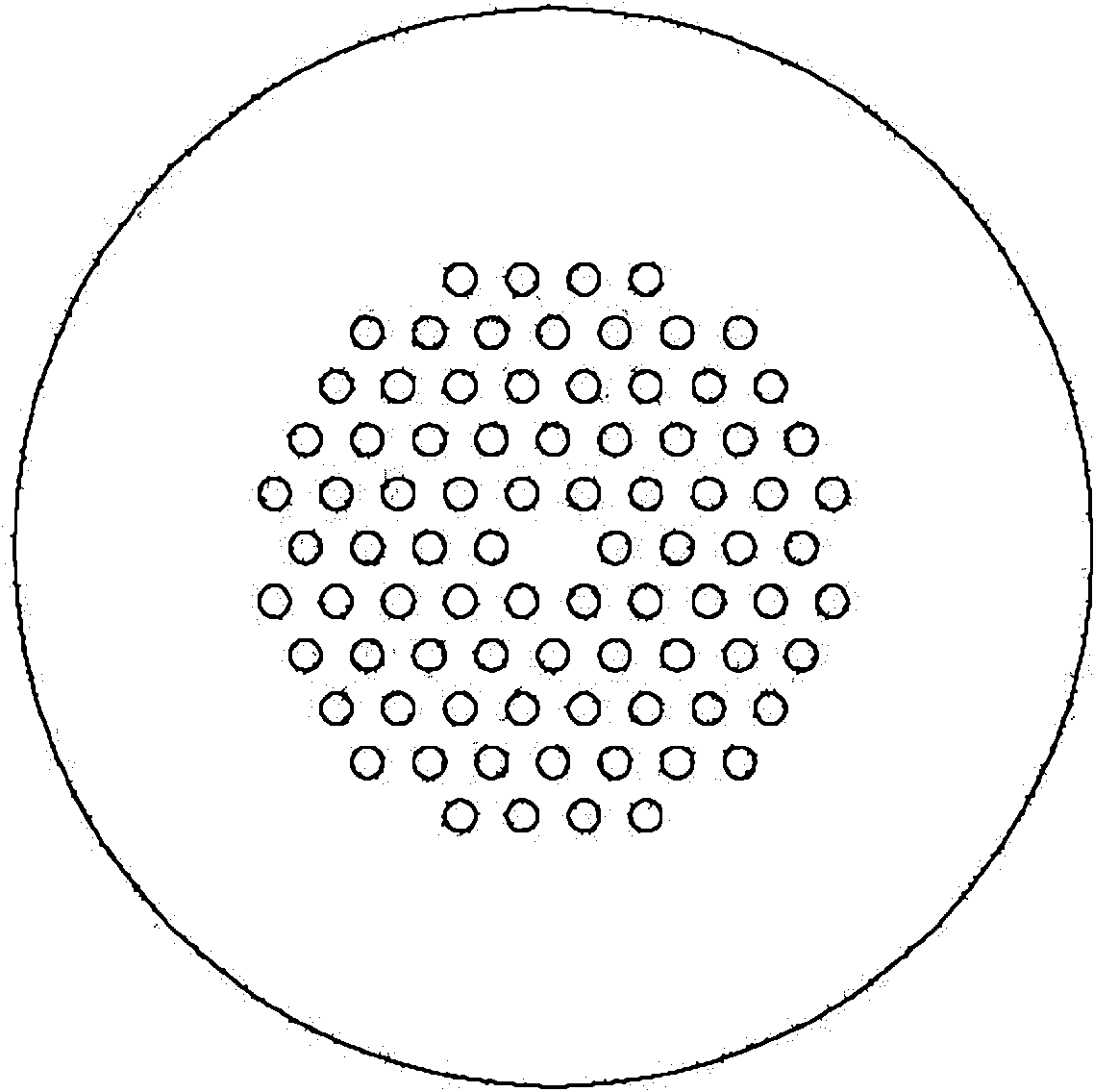

Method and system for rapidly optimizing drawing technology of photonic crystal fiber

InactiveCN102092937AQuick analysisAccurate analysisGlass making apparatusPhotonic crystalEngineering

The invention relates to a method for rapidly optimizing the drawing technology of the photonic crystal fiber. The method comprises the following steps in the drawing process of the photonic crystal fiber: cutting off a drawn and uncoated bare fibre, collecting the cross-sectional image of the drawn bare fibre; performing edge detection to the cross-sectional image of the bare fibre, reconstructing the geometrical structure of the cross section of the bare fibre; meshing the inside area of the cross section according to the reconstructed geometrical structure; adopting the numerical simulation method to analyze the photonic crystal fiber characteristics of the bare fibre; and comparing the analytical characteristics of the bare fibre with the design characteristics of the photonic crystal fiber to obtain a comparison result; adjusting the drawing technological parameters of the photonic crystal fiber according to the comparison result; and repeating the steps to ensure that the differences between the analytical characteristics of the drawn bare fibre and the design characteristics can be ignored and obtain a group of the optimized technological parameters for drawing the photonic crystal fiber.

Owner:BEIJING JIAOTONG UNIV

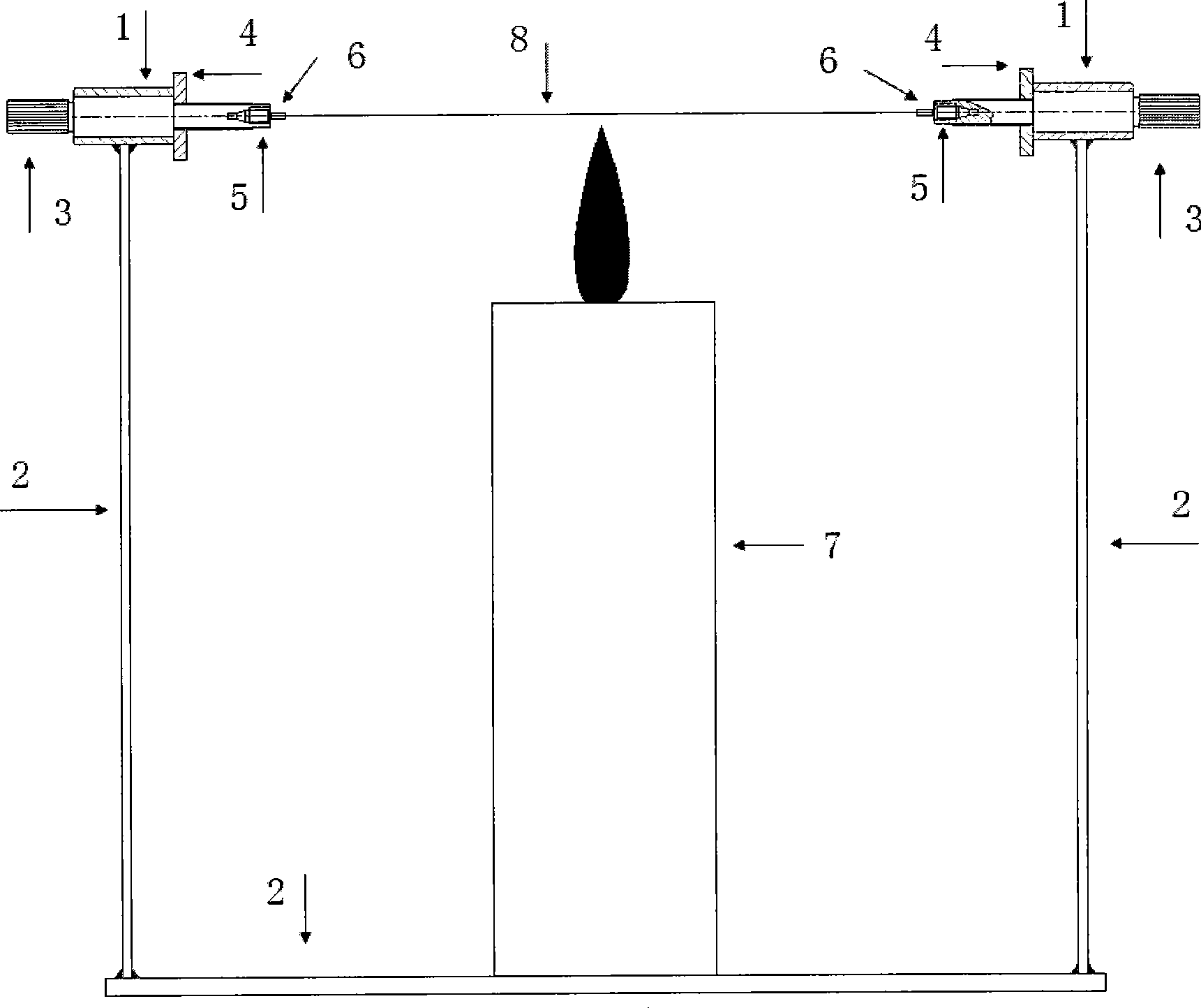

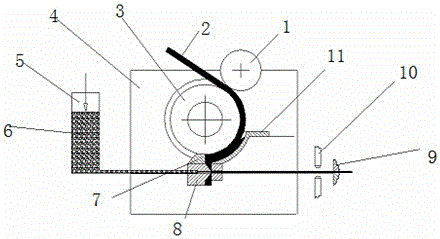

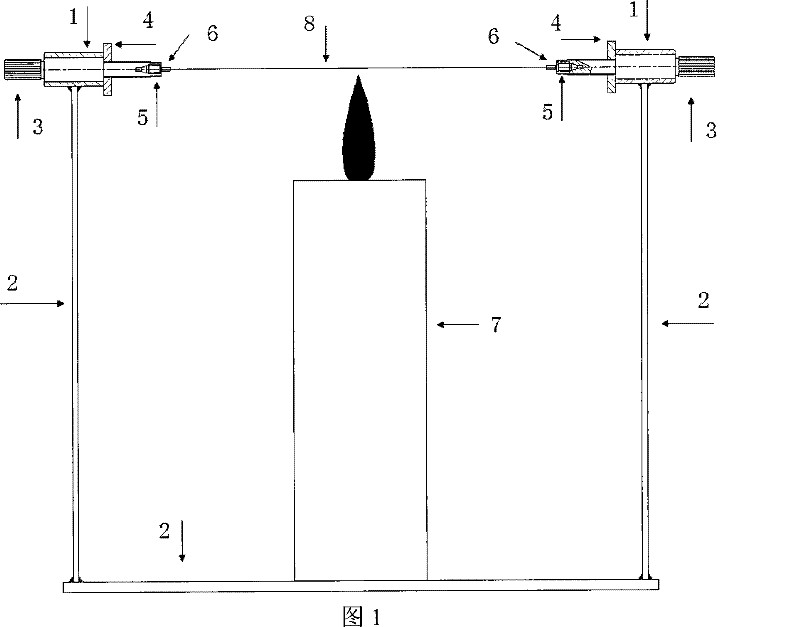

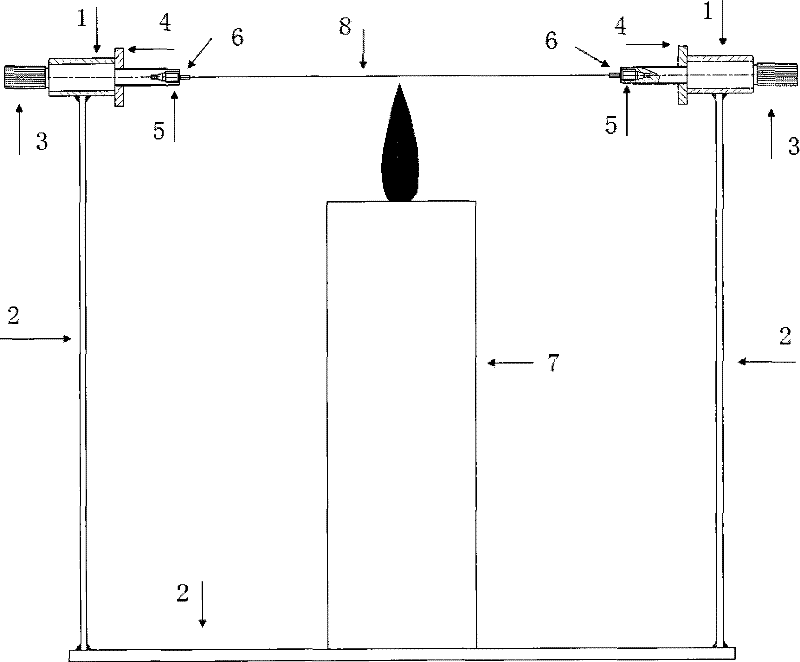

Device for making capillary pipe spray interface for co-using liquid chromatography and mass spectra

ActiveCN101382527AOptimizing the drawing processUniform reduction in inner and outer diametersComponent separationChromatographic separationManufacturing technology

The invention relates to the manufacture of an interface used for the combination of a liquid chromatographic separation system and a mass spectrum, in particular to a manufacturing device of a capillary spray interface used for the combination of liquid chromatogram and the mass spectrum, which comprises a 'U'-shaped bracket, two top ends of the 'U'-shaped bracket are respectively provided with a coaxial transverse sliding chute, hollow adjusting screw rods are respectively arranged in the sliding chutes and can transversely slide along the horizontal direction in the sliding chutes; the inner and outer surfaces of the inner side of the adjusting screw rod are respectively provided with internal screw threads and external screw threads, a PEEK head is screwed on the front end of the adjusting screw rod through the internal screw threads and internally passed by a polytetrafluoroethylene tube or a PEEK tube, an adjusting screw nut is arranged on the external screw threads; the interior of the 'U'-shaped bracket is provided with a high-temperature flame lamp; wherein, the inner chamber of the polytetrafluoroethylene tube or the PEEK tube is used for being sheathed with a quartz capillary. The device has simple manufacturing technology, uses raw materials with low price, and can comparatively and conveniently manufacture ideal mass spectrum spray interfaces with high mission success rate and good uniformity.

Owner:徐州脉析医疗技术有限公司

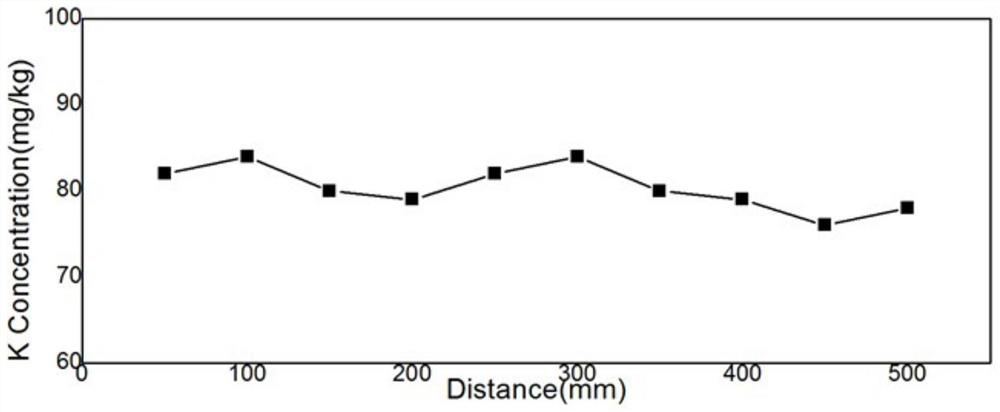

Ultra-low loss optical fiber preparation method and corresponding optical fiber

ActiveCN111847869AIncrease the effective areaMitigation of impairmentGlass making apparatusGlass fibre productsHydrofluoric acidPhysical chemistry

The invention provides a preparation method of an ultralow-loss optical fiber, which realizes uniform doping of alkali metal by optimizing a doping process. And meanwhile, the cladding adopts an F-doped technology to reduce the refractive index and optimize the wire drawing process, and finally, the development of ultralow-loss low-water-peak large-effective-area optical fiber products is realized. An optical fiber preform is manufactured in advance, and then the optical fiber preform is drawn to form an optical fiber. The method is characterized in that the manufacturing method of the opticalfiber preform comprises the following steps that: the core rod is prepared in advance through a VAD method; alkali metal neutral salt is used as a raw material in the preparation process of the ultralow-loss alkali-metal-doped optical fiber; an oxygen-enriched carrier gas is introduced into a sintering furnace core tube for alkali metal doping, the temperature in the doping process is controlledto be within the range of 1000-1800 DEG C, the doping time is controlled to be 2-6 hours, and an alkali metal doped core layer is prepared; and by washing the alkali metal doped core layer with hydrofluoric acid for 5-24 hours, the alkali metal doping concentration is 20-200 ppm.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

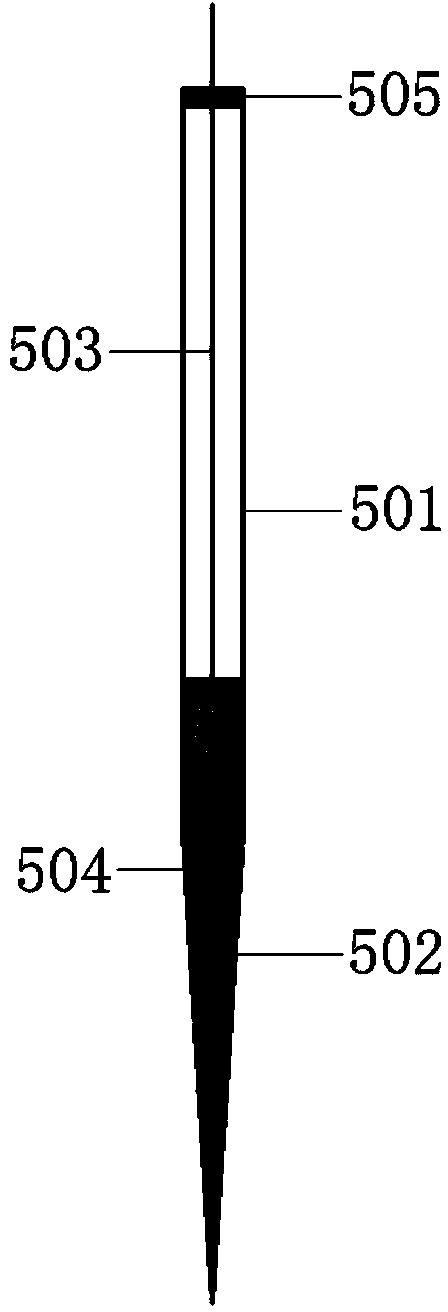

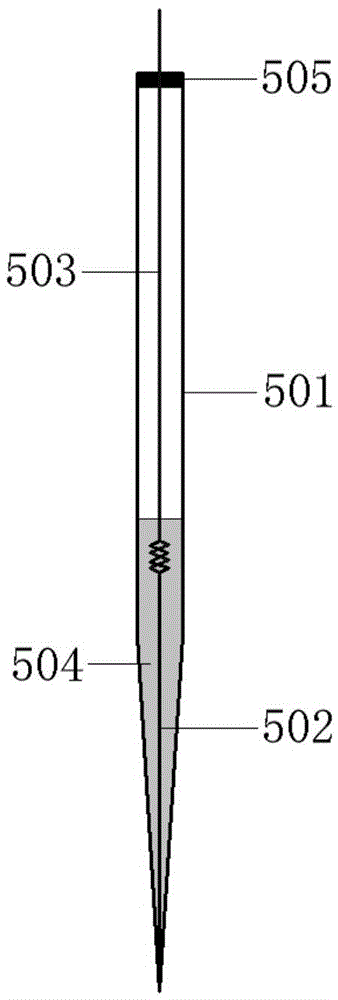

Discrete PO4<3-> ion selective micro electrode and preparation method thereof

ActiveCN103868968AContinuous determination of concentrationDetermination of concentrationMaterial analysis by electric/magnetic meansActivated sludgeEpoxy

The invention discloses a discrete PO4<3-> ion selective micro electrode and a preparation method thereof. The micro electrode comprises a tubular conical glass tube, wherein one end of the tubular conical glass tube is a conical tip, and the other end of the tubular conical glass tube is a cylindrical end face; a metal wire in middle wound connection penetrates through the tubular conical glass tube; a cobalt wire is arranged at one end of the metal wire in middle wound connection, and a fine copper wire is arranged at the other end of the metal wire; the cobalt wire and the fine copper wire respectively extend out of the conical end and the cylindrical end face of the tubular conical glass tube; the inner part of the tubular conical glass tube is filled with bismuth alloy coated with the cobalt wire and at the winding end; the cylindrical end face of the tubular conical glass tube is closed by an epoxy resin and is fixed with the fine copper wire. The preparation method comprises the following steps: drawing the tubular conical glass tube, etching and mounting the cobalt wire, filling the bismuth alloy and assembling the micro electrode. The spatial distribution characteristics of concentration of phosphate (comprising metaphosphate) inside activated sludge groups and natural water body sediments can be rapidly and continuously measured.

Owner:陕西省膜分离技术研究院有限公司

Method for melting copper through line frequency furnace

ActiveCN105274354AImprove airtightnessImprove energy savingProcess efficiency improvementIngotShaft furnace

The invention discloses a method for melting copper through a line frequency furnace. The method comprises the following steps that 1, a waste copper piece and waste are subjected to primary treatment; 2, screening is carried out; 3, classification is carried out; 4, accessories are fed into furnaces, wherein the accessory I, the accessory II and the accessory III are fed into the shaft furnace, the open-hearth furnace and the line frequency cored copper melting copper to be refined, and a product I, a product II and a product III are obtained; 5, the product I and the product II are transported to a copper continuous casting and rolling unit for casting treatment, a steel rod is obtained, and the product III is placed in a pig casting machine to be machined and treated, and a copper ingot is obtained; and 6, the steel rod in the step 5 is drawn, and a qualified copper piece is obtained. The method for melting copper through the line frequency furnace achieves energy saving and is environmentally friendly, and manufactured steel is good in quality.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

Glass optical fiber for neutron detection, scintillation material and preparation method thereof

PendingCN111302643AAchieve total reflectionHigh position resolutionGlass making apparatusMeasurement with scintillation detectorsNuclear physicsCore (optical fiber)

The invention provides a glass optical fiber for neutron detection. The glass optical fiber comprises a fiber core and a cladding tube coating the outer layer of the fiber core, the fiber core is madeof a scintillation material and is used as a scintillator of the neutron detector; and the cladding tube is made of a high-purity quartz material and is used as a scintillator shell of the neutron detector. The scintillation material is prepared into the glass optical fiber so that total reflection of scintillation of activator ions in the fiber core can be realized; when the glass optical fiberis used for neutron and gamma ray detection, the position resolution of thermal neutron detection can be greatly improved, and the glass optical fiber is easy to design and process into various detector structures. The invention also provides a preparation method for preparing the glass optical fiber.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Copper rod material and machining method of copper alloy rod material

The invention provides a copper rod material and a machining method of a copper alloy rod material. The machining method comprises the following steps that firstly, a to-be-machined rod material is connected through cold pressing welding; 2, the outer circumferential face of the connected to-be-machined rod material is cut and scraped; 3, the to-be-machined rod material is conveyed into a heatingcavity, the heating cavity is filled with an inert protective gas, and a heating device installed in the heating cavity heats the to-be-machined rod material; and 4, the to-be-machined rod material isextruded through an extruding machine and then is outputted. The method is simple in operation process and high in efficiency, and the prepared copper rod material and the prepared copper alloy rod material are excellent in performance.

Owner:SHANGHAI ELECTRIC CABLE RES INST

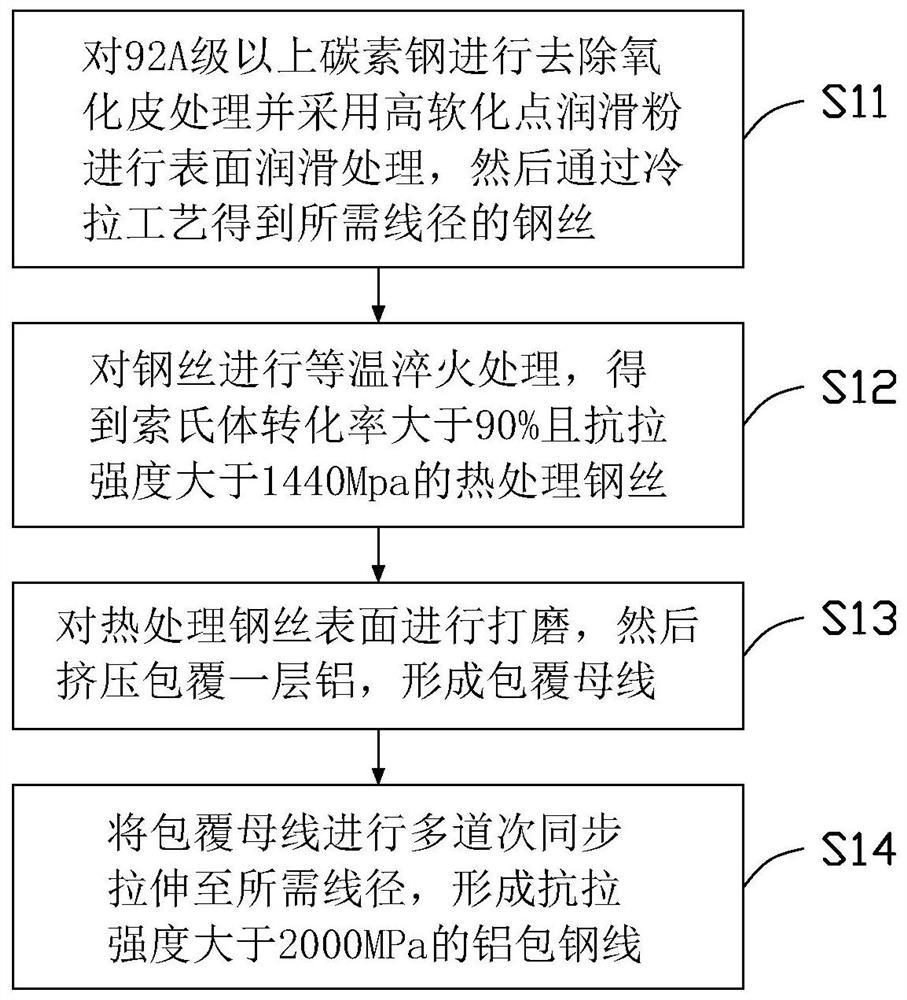

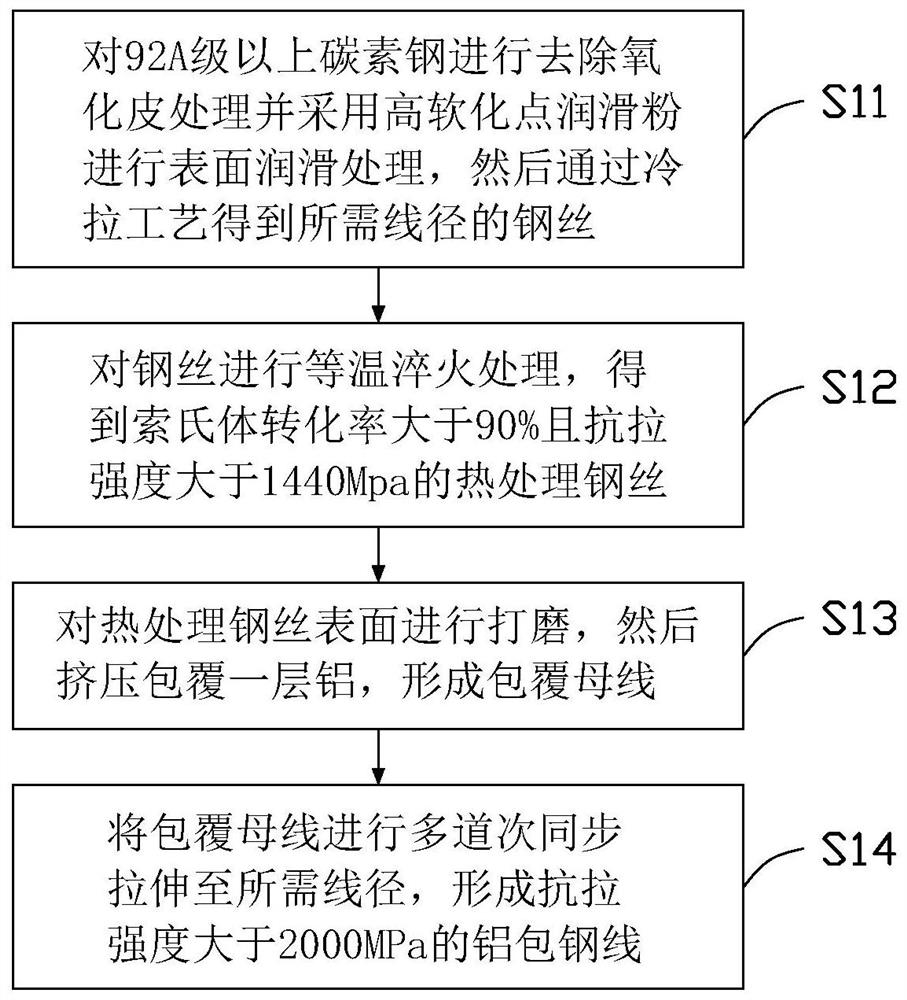

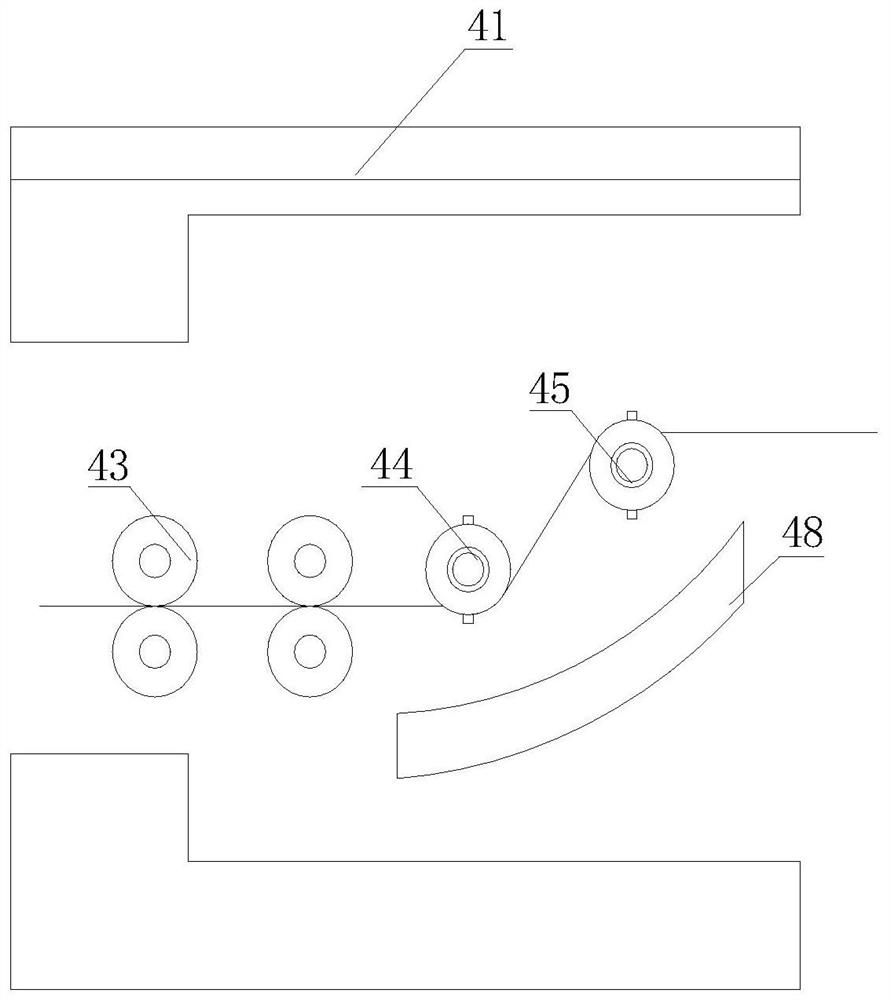

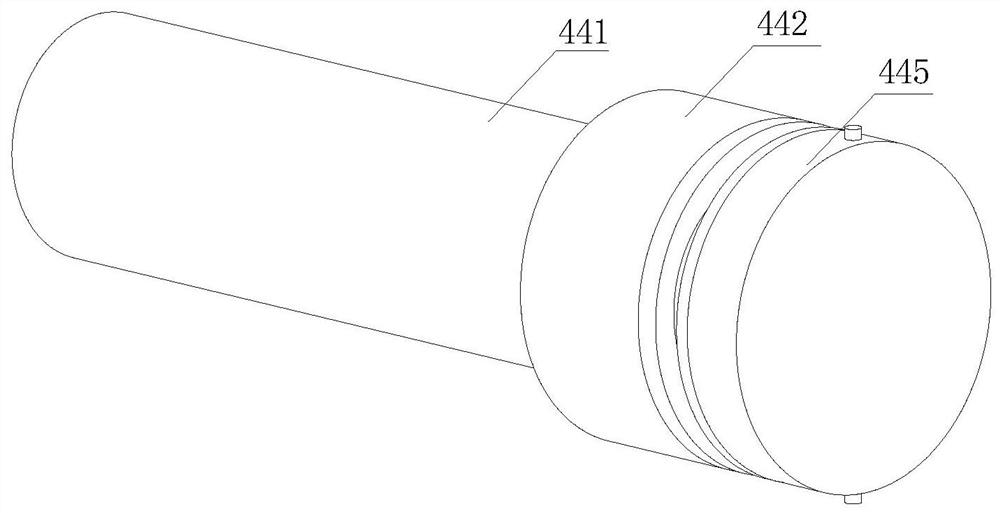

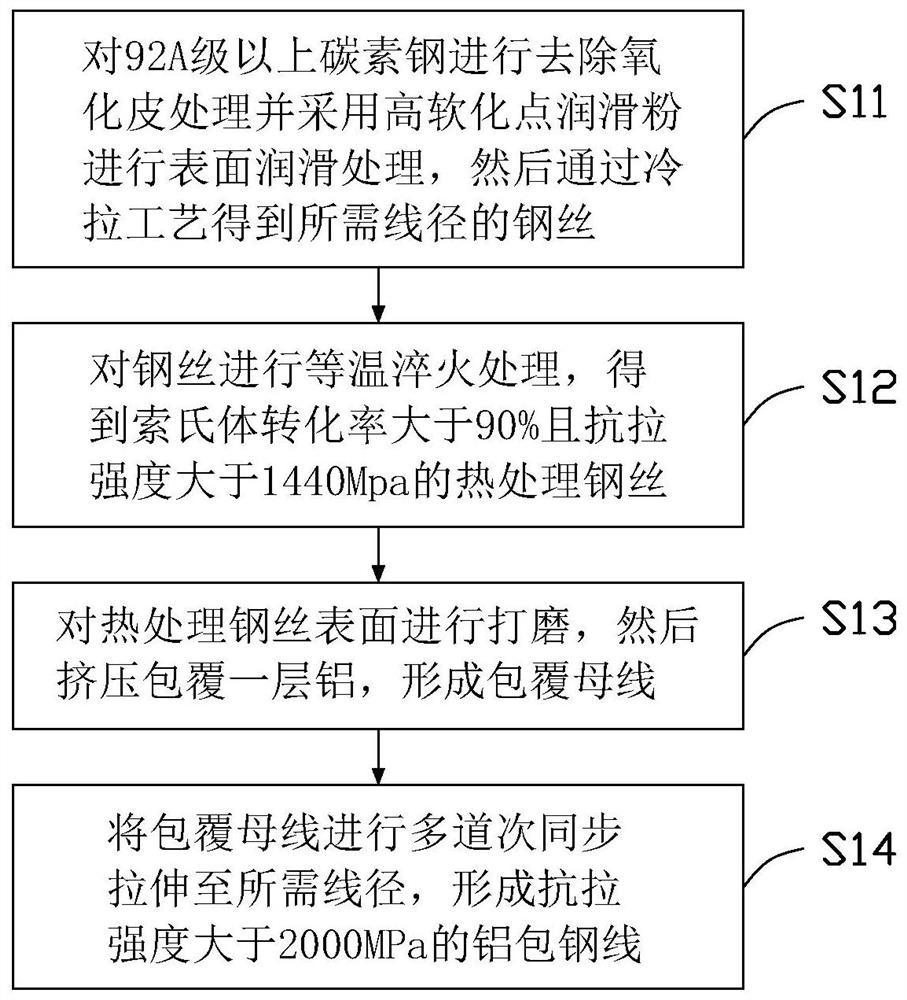

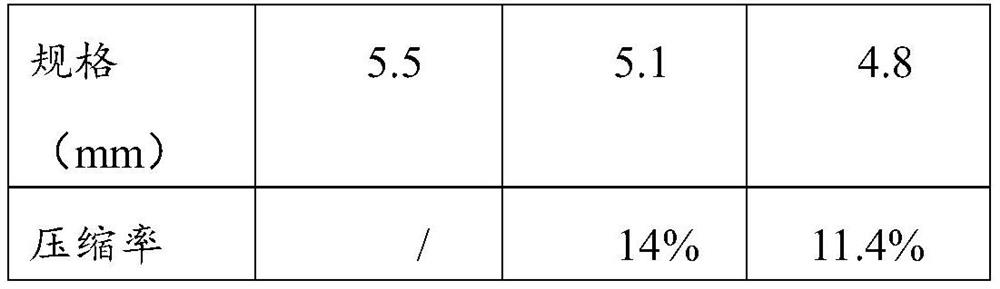

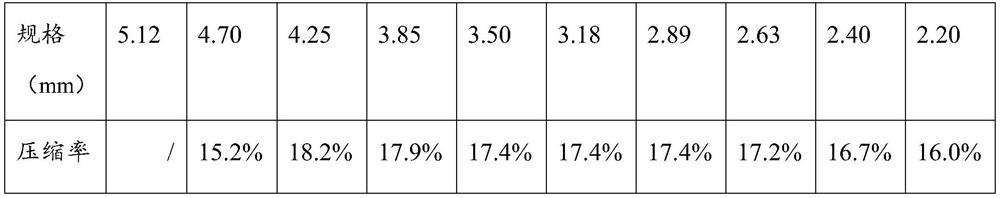

Aluminum-clad steel wire and preparation method thereof

ActiveCN111822540AHas tensile strengthSimple stepsFurnace typesHeat treatment furnacesAustemperingBusbar

The invention provides a preparation method for an aluminum-clad steel wire. The preparation method for the aluminum-clad steel wire comprises the following steps that oxide skin removing treatment isconducted on carbon steel which is above the 92A level, high-softening point lubricating powder is adopted to conduct surface lubrication, and then the steel wire with the needed wire diameter is acquired through a cold drawing technology; continuous isothermal quenching treatment is conducted on the steel wire, and the heat-treated steel wire with sorbite conversion rate greater than 90 percentand tensile strength greater than 1440 Mpa is acquired; the surface of the heat-treated steel wire is polished, a layer of aluminum is clad on the steel wire through extrusion, and a clad busbar is formed; and multi-pass synchronous drawing is conducted on the clad busbar until the needed wire diameter is acquired, and the aluminum-clad steel wire with tensile strength greater than 2000 Mpa is formed. The provided preparation method for the aluminum-clad steel wire is simple in steps and convenient to operate; the high-softening point lubricating powder is utilized, a rough drawing productiontechnology is optimized, parameters such as the total compression ratio and the pass compression ratio are adjusted, the aluminum-clad steel wire duplex metal drawing technology is optimized, and theprepared aluminum-clad steel wire has the tensile strength which is above 2000 Mpa.

Owner:ZHONGTIAN ELECTRIC POWER OPTICAL CABLES CO LTD +1

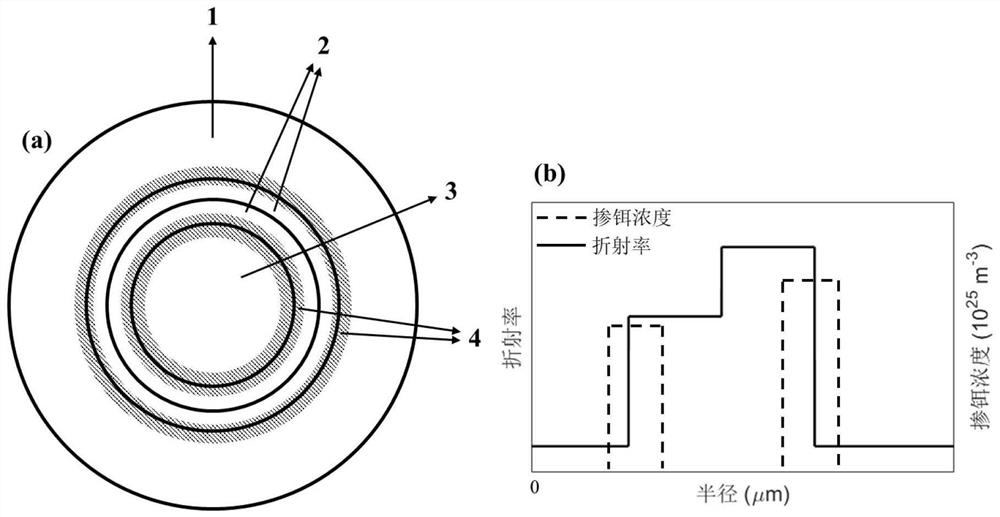

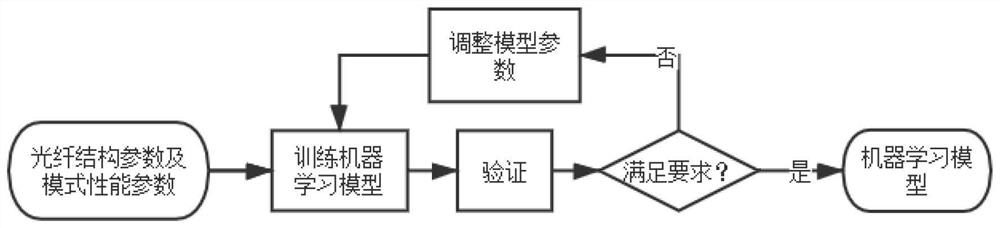

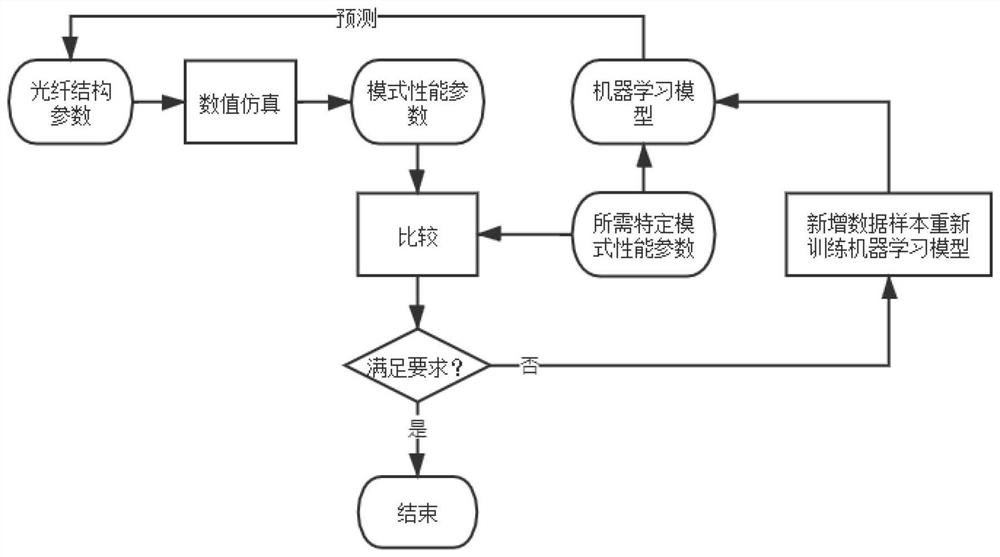

Multi-parameter optimized orbital angular momentum erbium-doped optical fiber

ActiveCN113156574AUniform gainReduce differential mode gainClimate change adaptationOptical fibre with multilayer core/claddingFiberRefractive index

The invention discloses a multi-parameter optimized orbital angular momentum erbium-doped optical fiber, and belongs to the field of optical fiber communication. The multi-parameter optimized orbital angular momentum erbium-doped optical fiber includes an annular fiber core region, an erbium-doped region, a central region and a cladding. The annular fiber core area is of a multi-layer annular fiber core structure, the erbium-doped area is a double-layer annular erbium-doped area composed of the inner side and the outer side of the annular fiber core area, and the refractive index of the center area and the refractive index of the cladding are lower than that of the annular fiber core area. Multi-parameter optimization is carried out on optical fiber structure parameters of the orbital angular momentum erbium-doped optical fiber by using a machine learning method to obtain mode performance parameters of a specific target. Meanwhile, the orbital angular momentum Er-doped optical fiber can be expanded into a multi-core orbital angular momentum Er-doped optical fiber which comprises a plurality of fiber cores. The multi-parameter optimized orbital angular momentum erbium-doped optical fiber solves the problem of multi-parameter optimization design of the orbital angular momentum erbium-doped fiber, has application prospects in the fields of orbital angular momentum fiber amplifiers, lasers and optical communication, and fills the blank in the related technical fields.

Owner:HUAZHONG UNIV OF SCI & TECH

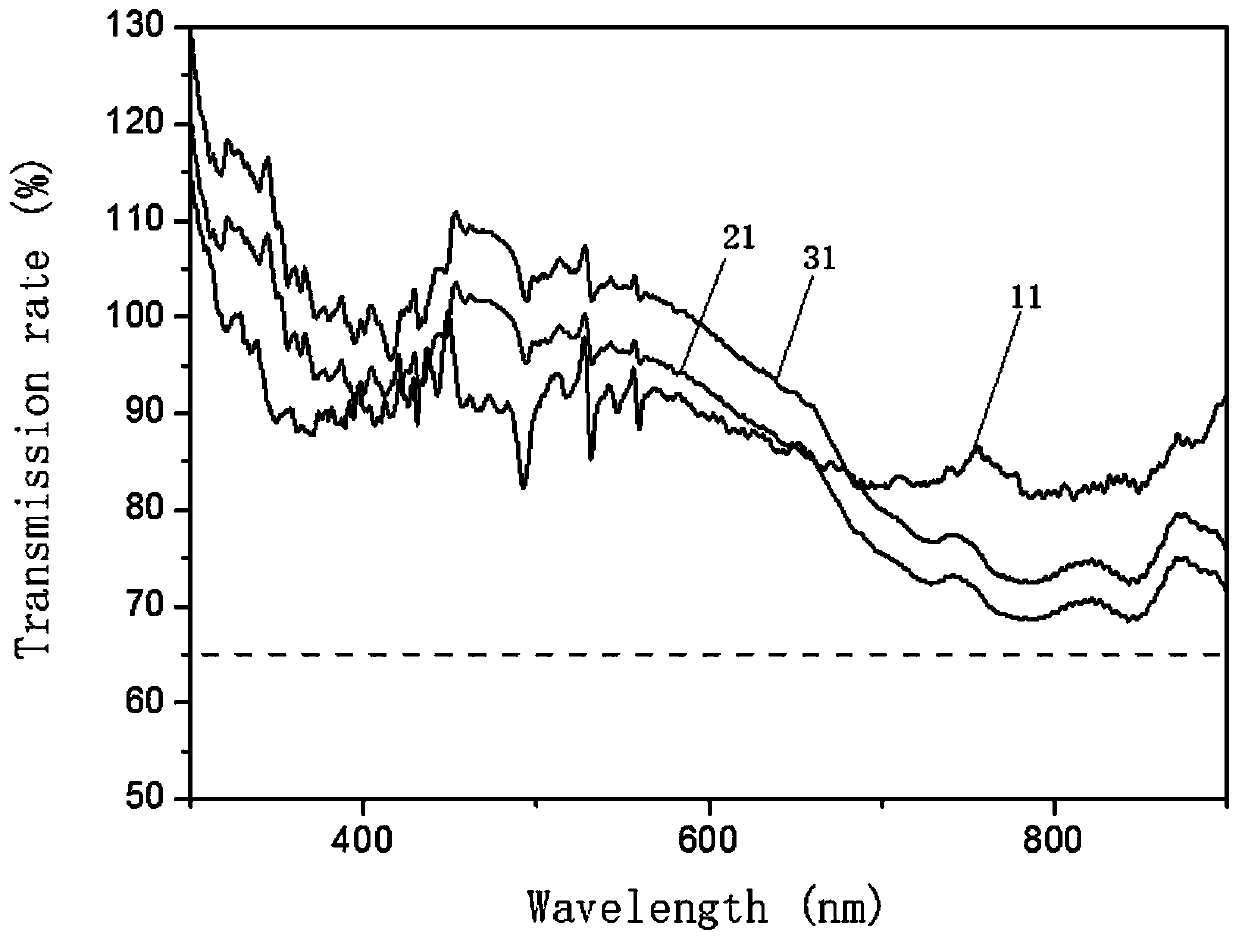

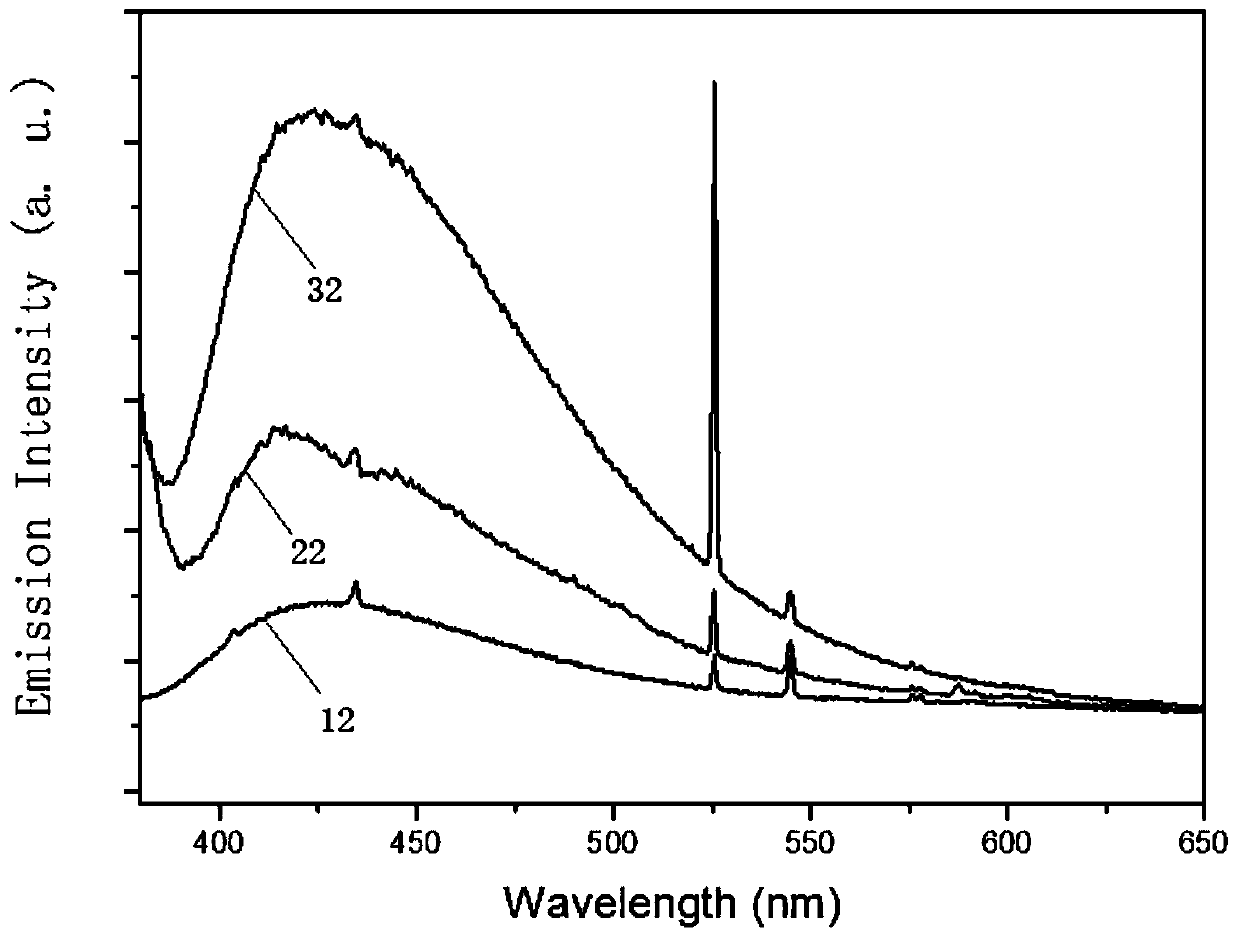

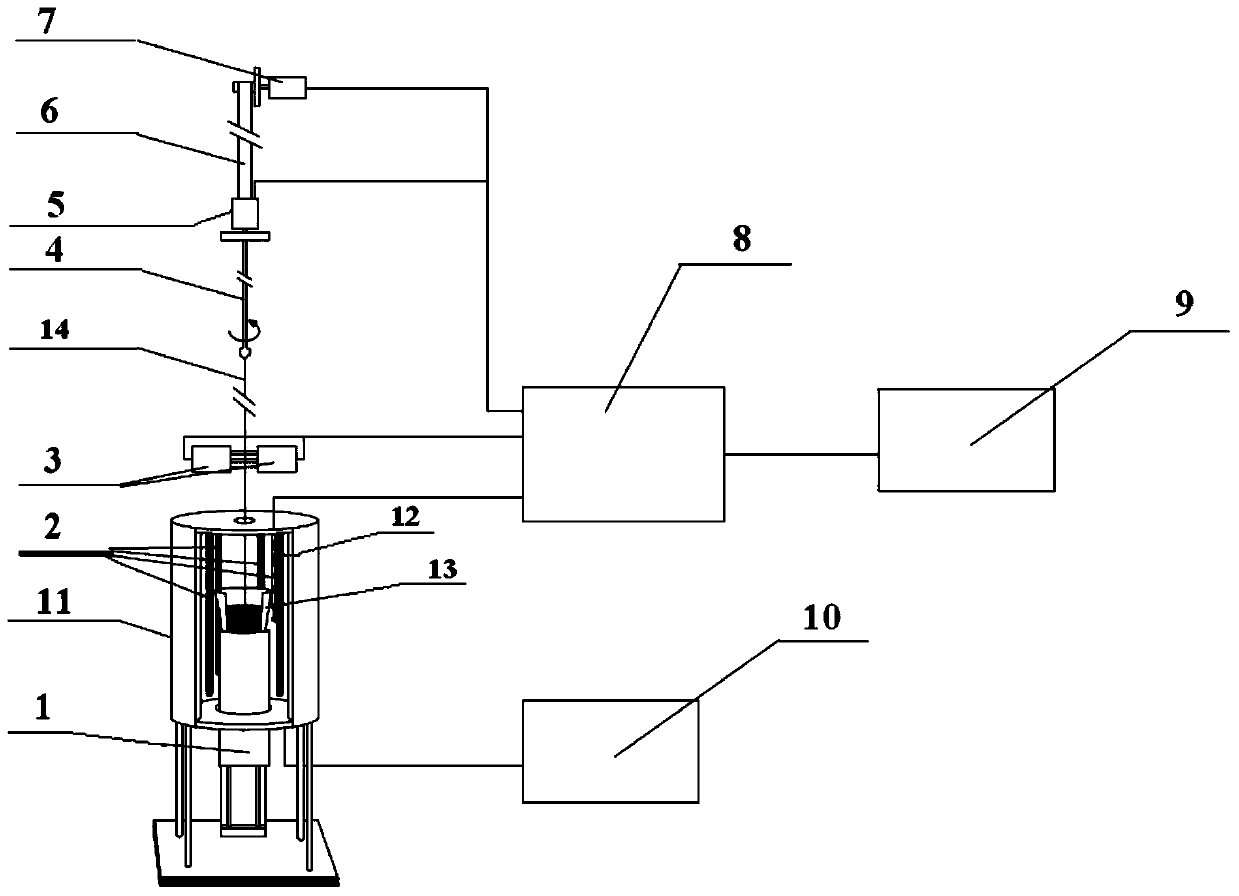

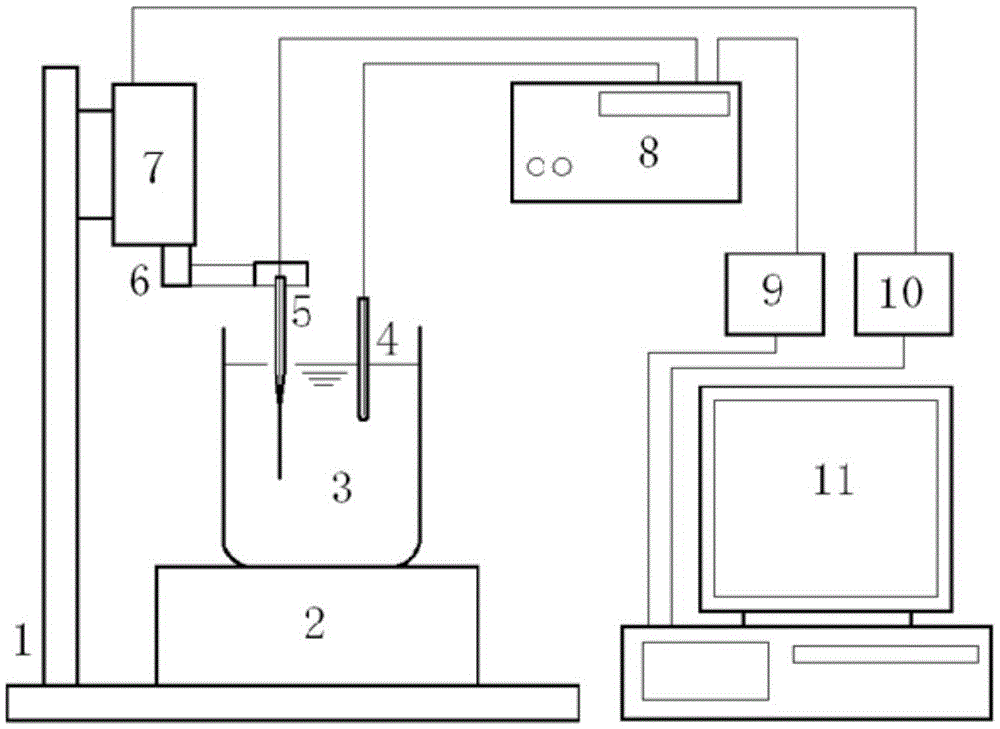

A glass wire drawing machine and a method for drawing glass filaments using the glass wire drawing machine

The invention relates to the field of glass detection, and discloses a glass spinning machine, and a method for spinning glass fibers through adopting the glass spinning machine. The glass spinning machine comprises: a heating unit; a refractory material pedestal (1) used for sending a glass sample to the heating unit and capable of selectively rotating; a lifting traction unit providing upward traction force; a sticking device (4), wherein one end of the sticking device is connected with the lifting traction unit, and the other end of the sticking device is used for sticking molten glass; and a first control unit comprising a laser amesdial (3) and a controller (8), wherein the laser amesdial is used for measuring the diameter value of the glass fibers and feeding the diameter value to the controller, and the controller regulates traction force provided by the lifting traction unit according to the measured diameter value and a preset value. The glass spinning machine is an upward pulling glass fiber molding device, the glass fibers with uniform diameter can be fully-automatically and conveniently spun through spinning the glass fibers by using the glass spinning machine, and the glass spinning machine is suitable for various types of glass spinning.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

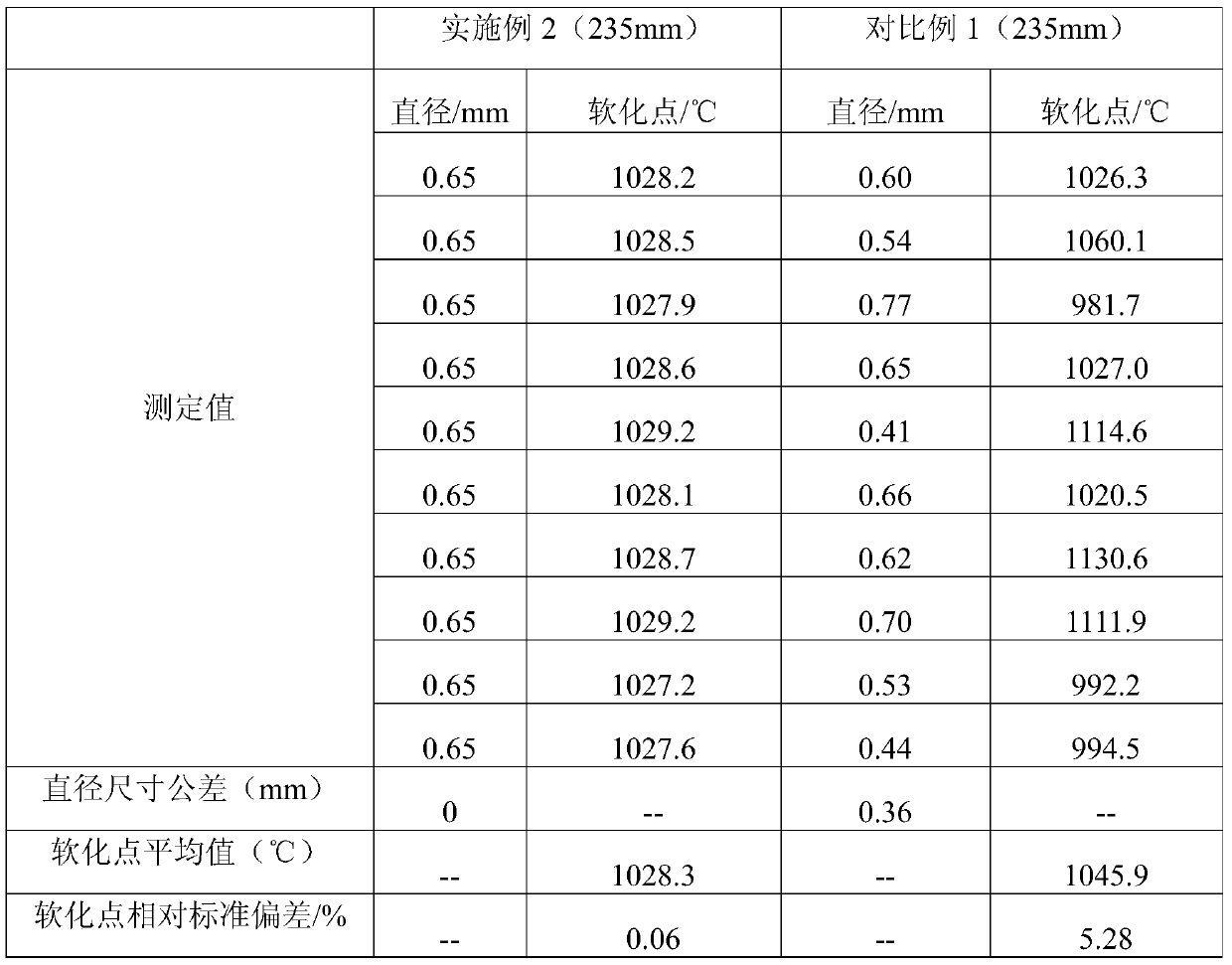

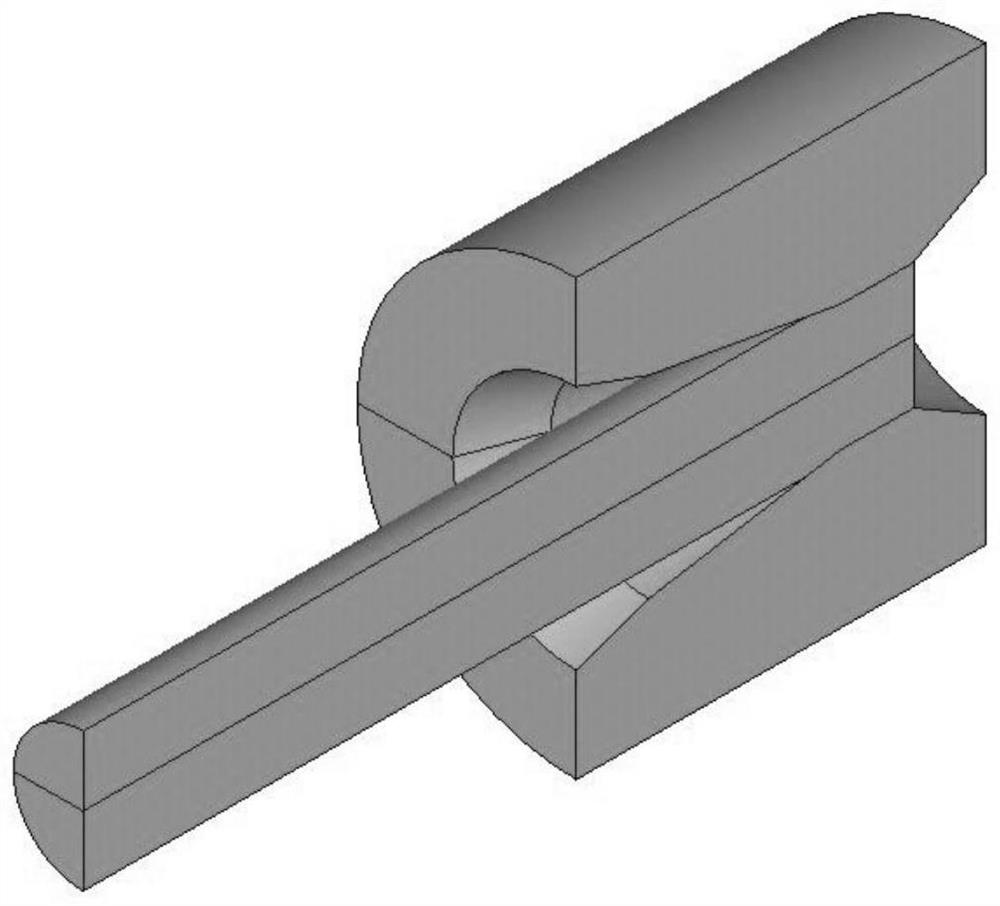

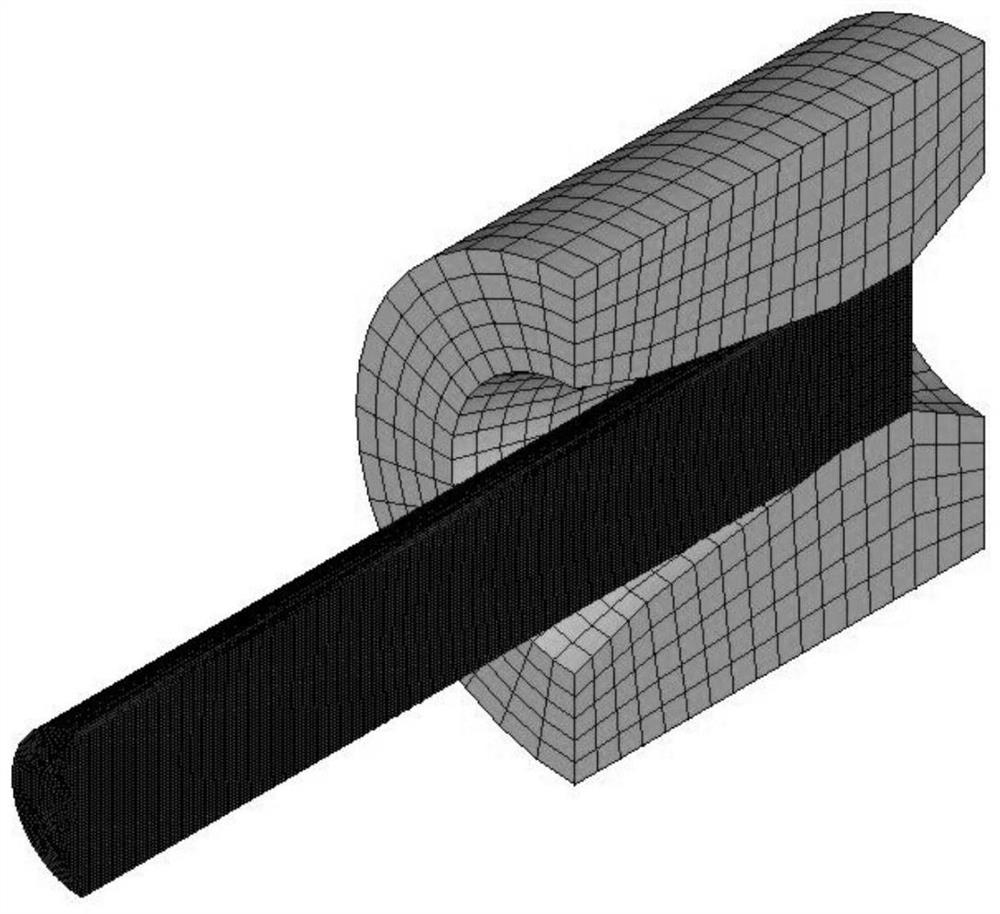

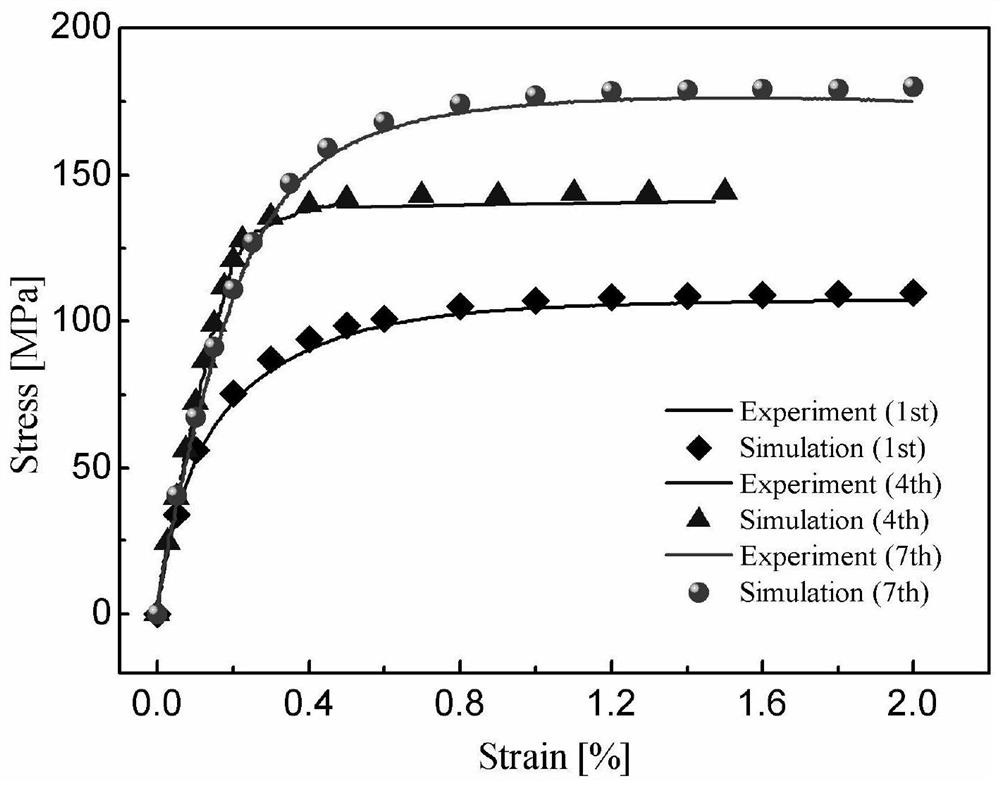

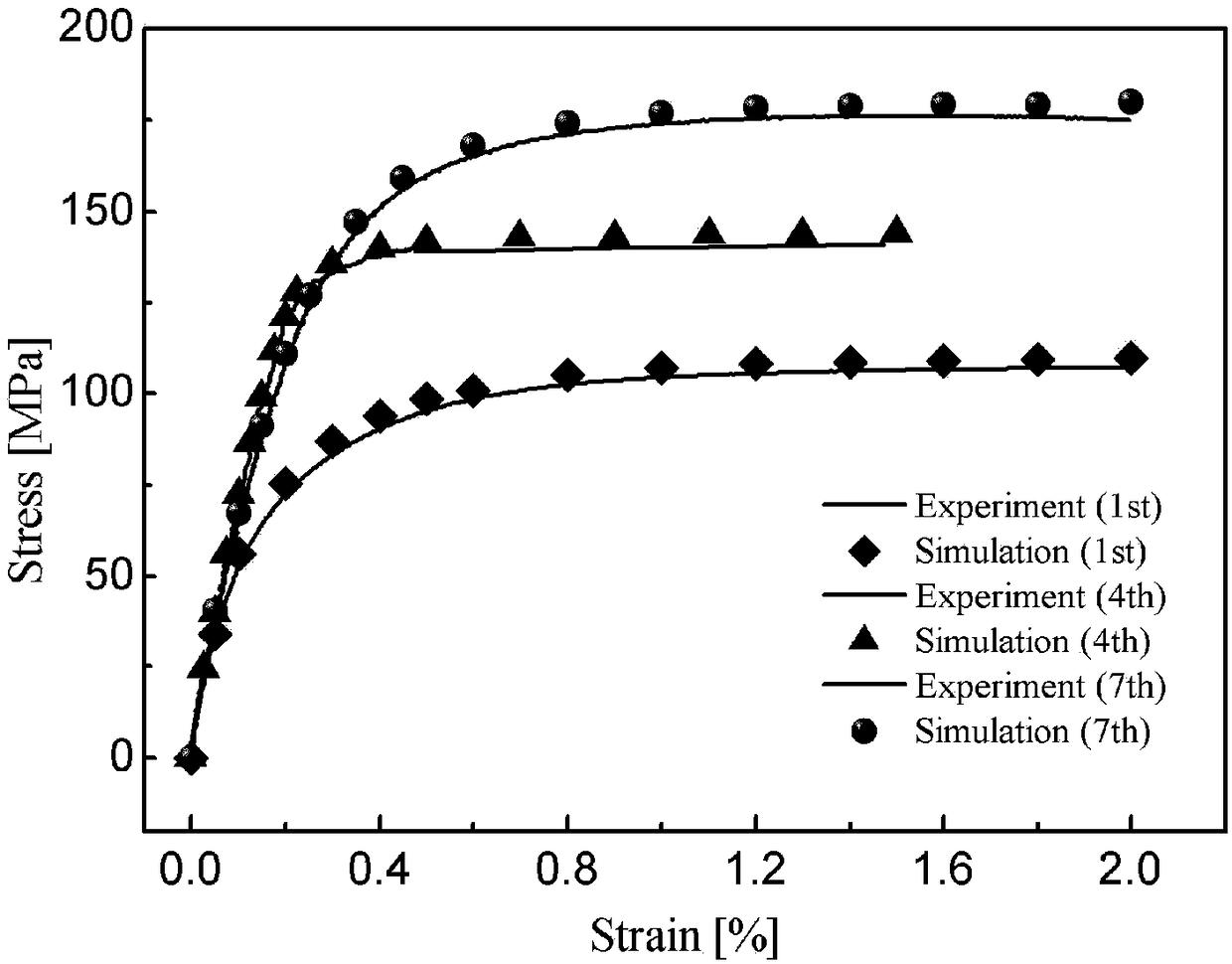

Prediction method of plastic deformation mode for multi-pass cold drawing of pure aluminum conductor based on ANSYS/LS-DYNA

ActiveCN108509666BHigh breaking strengthOptimizing the drawing processGeometric CADDesign optimisation/simulationStress distributionElement model

The invention discloses a method for predicting the plastic deformation mode of multi-pass cold drawing of industrial pure aluminum wires based on ANSYS / LS-dyna, which mainly includes: establishing based on ANSYS parametric modeling technology according to the process parameters of pure aluminum wires and molds The solid model of the wire and the mold; according to the large deformation behavior of the wire during the drawing process, select the dynamic hardening material model and determine the parameters of the material model according to the tensile stress-strain curve of each pass wire; according to the wire drawing on the wire drawing machine The traction mode and pulling speed determine the loading mode and boundary conditions of the finite element model; finally, the defined finite element analysis model is submitted to LS-dyna for calculation, and the result file is post-processed with ANSYS, and the stress distribution and plastic deformation cloud diagram are output, and Draw the stress change curve from the core to the surface of each pass. The invention improves the existing wire simulation method, improves the calculation efficiency and calculation accuracy, greatly shortens the verification time of process parameters and reduces the design cost compared with the test method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Crystal growth device and growth method

ActiveCN112281210BOptimizing the drawing processDrawing solutionBy pulling from meltCrucibleEngineering

The application provides a crystal growth device and growth method, including a furnace body, a crucible, a cooling jacket and a flow guide tube, the cooling jacket is set inside the furnace body to cool the crystal, and the flow guide tube is set on the periphery of the cooling jacket , the guide tube includes an upper guide tube part and a lower guide tube part, the upper guide tube part is cylindrical and arranged around the cooling jacket, and the lower guide tube part is arranged at the lower end of the upper guide tube part and is located on the cooling jacket On the lower side of the crucible, the lower guide tube is a hollow upper, lower, and small circular platform structure. A groove is formed on the inner peripheral wall of the circular platform structure. The top of the groove runs through the circular platform structure, and the cooling jacket moves along the axial direction of the crucible. In this growth device, the cooling jacket moves along the axial direction of the crucible, which affects the distribution of the thermal field in the furnace body, and can fine-tune the temperature gradient at the solid-liquid interface, so that crystals in a defect-free growth area with a certain width can be drawn, which solves the problem of the existing technology. The temperature gradient at the solid-liquid interface is difficult to control, resulting in the pulling of crystals in the growth region with more defects.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

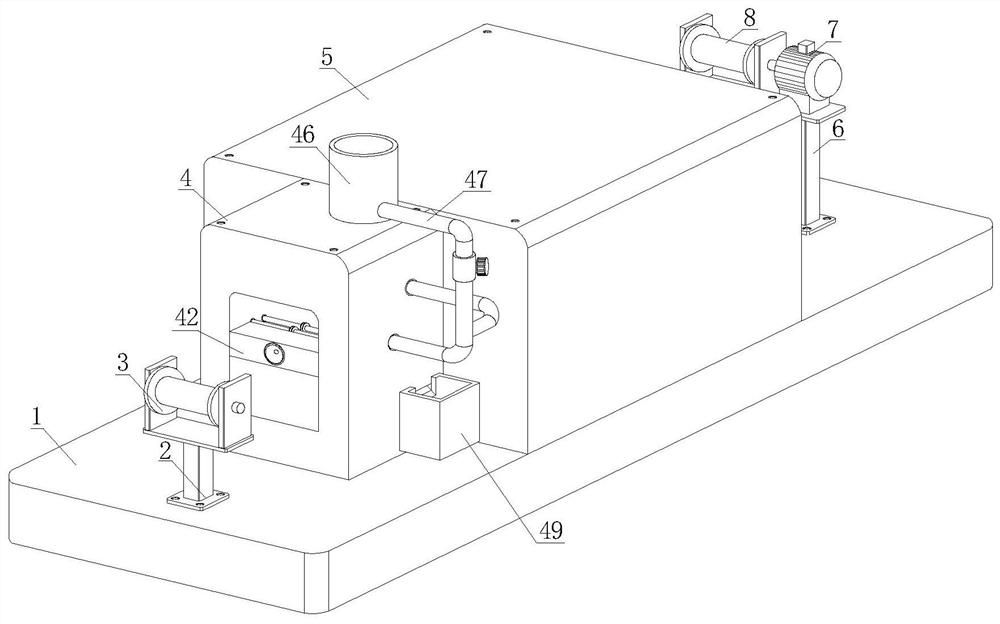

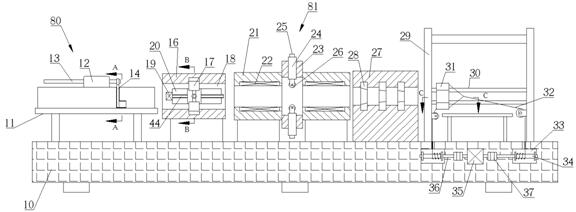

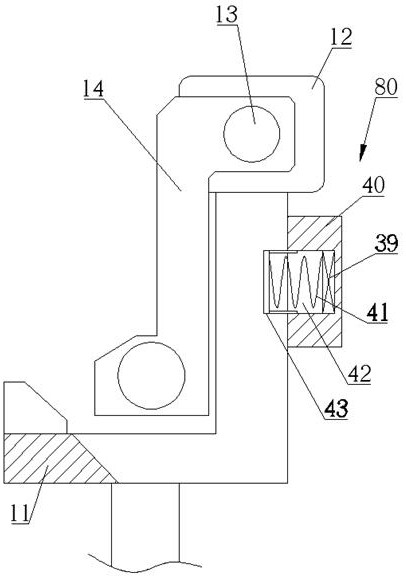

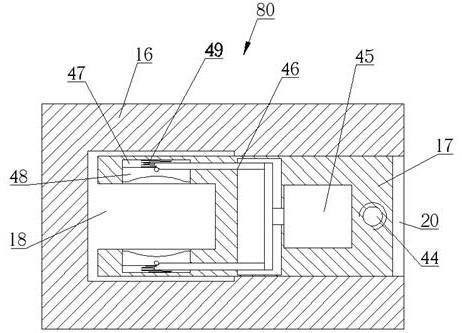

A copper wire drawing device for cable production and its drawing method

ActiveCN112037999BOptimizing the drawing processReduce damageDrawing diesReduction of cables/conductors sizeCopper wireElectric machinery

The invention discloses a copper wire drawing device for cable production and a drawing method thereof, comprising a pay-off reel, a lubricating mechanism, a drawing host, a driving motor and a take-up reel, and the pay-off reel is arranged on the upper end of a first support frame , a lubricating mechanism is provided on the upper end side of the support base close to the pay-off reel, the lubricating mechanism is connected and communicated with the inlet end of the drawing main machine, and one end of the take-up reel is connected with the output end of the driving motor; the beneficial effects of the present invention: make The whole steel wire is evenly coated with a layer of drawing liquid, which is convenient for the later drawing of the steel wire, and the drawing liquid will not be sprayed to other mechanisms, which greatly improves the utilization rate of the drawing liquid. There is basically no rigid friction of the steel wire, which reduces the damage to the steel wire by the mechanism, ensures the quality of the final drawn steel wire, facilitates the application of drawing oil before drawing the copper wires of different specifications, and improves the flexibility of the drawing device. It takes up less space and is easy to promote and use.

Owner:揭西县三保铜材有限公司

Processing method of copper rod and copper alloy rod

The invention provides a processing method for copper rods and copper alloy rods, comprising the following steps: step 1: using cold pressure welding to connect the rods to be processed; step 2: connecting the outer circumference of the rods to be processed cutting and scraping treatment on the surface; step 3: transport the rod to be processed into the heating chamber, which is filled with inert protective gas, and the heating device installed in the heating chamber The processed rod is heated; step 4: the rod to be processed is extruded by an extruder and then output. The method of the invention has simple operation process and high efficiency, and the prepared copper rod material and copper alloy rod material have excellent properties.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Aluminum-clad steel wire and its preparation method

ActiveCN111822540BHas tensile strengthSimple stepsFurnace typesHeat treatment furnacesBusbarCarbon steel

The invention provides a method for preparing aluminum-clad steel wire, which includes the following steps: removing scale from carbon steel above grade 92A and lubricating the surface with high softening point lubricating powder, and then obtaining the required wire diameter through cold drawing process Steel wire; the steel wire is subjected to continuous isothermal quenching treatment to obtain a heat-treated steel wire with a sorbite conversion rate greater than 90% and a tensile strength greater than 1440Mpa; the surface of the heat-treated steel wire is polished, and then extruded and coated with a layer of aluminum to form a coated busbar; The coated busbar is stretched synchronously to the required wire diameter for multiple passes to form an aluminum-clad steel wire with a tensile strength greater than 2000MPa. The preparation method of the aluminum-clad steel wire provided by the present invention has simple steps and convenient operation. The lubricating powder with a high softening point is used to optimize the rough drawing production process, and the parameters such as the total compression rate and the pass compression rate are adjusted to optimize the bimetallic aluminum-clad steel wire. Drawing process, the prepared aluminum-clad steel wire has a tensile strength of more than 2000Mpa.

Owner:ZHONGTIAN ELECTRIC POWER OPTICAL CABLES CO LTD +1

A hexagonal steel bar drawing machine tool

The invention discloses a hexagonal steel bar drawing machine tool. The hexagonal steel bar drawing machine tool comprises a base placed on the ground. A discharging table is fixedly mounted on the top surface of the base. A conveying base is fixedly mounted on the right side of the discharging table. When a steel bar is placed on the discharging table, a push plate is pressed backwards by a pushplate and drives a first push spring to press a pressure controller. The pressure controller controls a pushing cylinder to not start. The steel bar can be directly machined to form a hexagonal steelbar. Under the condition that materials do not need to be removed, the steel bar to be machined can be machined to form a required part and can be subjected to heating treatment first. The required shape of the hexagonal steel bar can be better formed through drawing of the treated steel bar. The steel bar is pushed through different ways. Raw materials of the steel bar can be prevented from beingdamaged during drawing.

Owner:日信电气股份有限公司

A high-performance glass fiber

ActiveCN104445965BImprove high temperature resistanceGood chemical stabilityGlass making apparatusYarnGlass fiber

The invention discloses a high-performance glass fiber and relates to the technical field of glass fiber yarns. The high-performance glass fiber consists of the following components in percentage by weight: 54.8-56.2% of SiO2, 10.5-12.5% of Al2O3, 19.8-21.3% of CaO, 3.2-4.5% of MgO, 23-25% of RO=(CaO+MgO), 2.9-4.1% of TiO2, 0.5-2.0% of K2O, 1-3% of ZnO, 0.1-0.5% of Fe2O3 and 1-2% of LiO2. Titanium and lithium are introduced, so that the structure of the glass fiber is changed for facilitating improvement on the mechanical strength, high temperature resistance and chemical stability of the glass. The high-performance glass fiber has a relatively low molding temperature and a relatively low liquid phase line temperature, can be used for reducing the glass devitrification risk and keeping relatively high mechanical strength, and is beneficial to good drawing of the glass fiber.

Owner:江西大华新材料股份有限公司

A method for melting copper in a power frequency furnace

ActiveCN105274354BImprove airtightnessImprove energy savingProcess efficiency improvementIngotShaft furnace

The invention discloses a method for melting copper through a line frequency furnace. The method comprises the following steps that 1, a waste copper piece and waste are subjected to primary treatment; 2, screening is carried out; 3, classification is carried out; 4, accessories are fed into furnaces, wherein the accessory I, the accessory II and the accessory III are fed into the shaft furnace, the open-hearth furnace and the line frequency cored copper melting copper to be refined, and a product I, a product II and a product III are obtained; 5, the product I and the product II are transported to a copper continuous casting and rolling unit for casting treatment, a steel rod is obtained, and the product III is placed in a pig casting machine to be machined and treated, and a copper ingot is obtained; and 6, the steel rod in the step 5 is drawn, and a qualified copper piece is obtained. The method for melting copper through the line frequency furnace achieves energy saving and is environmentally friendly, and manufactured steel is good in quality.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

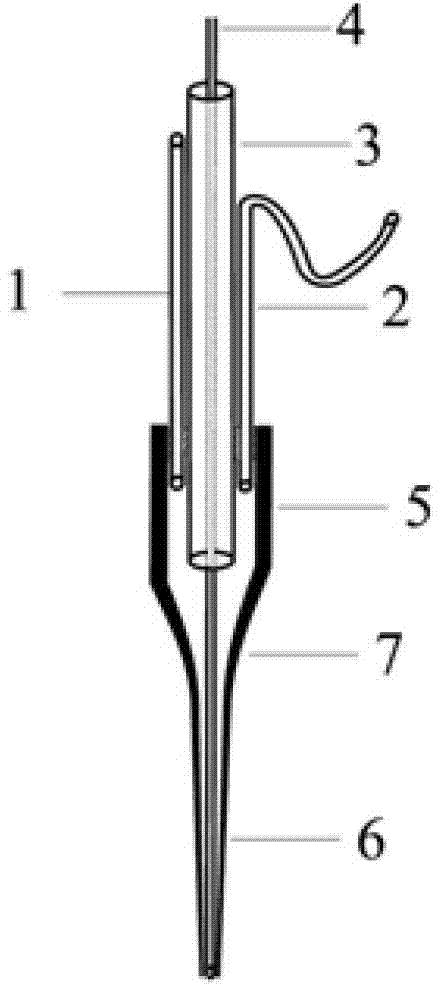

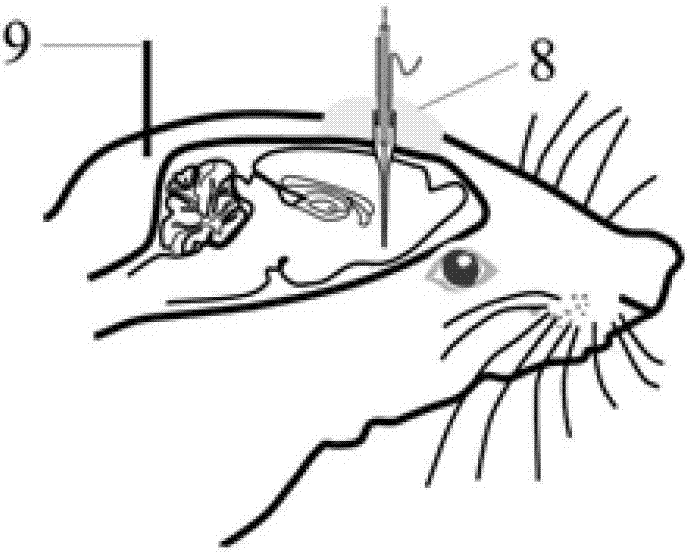

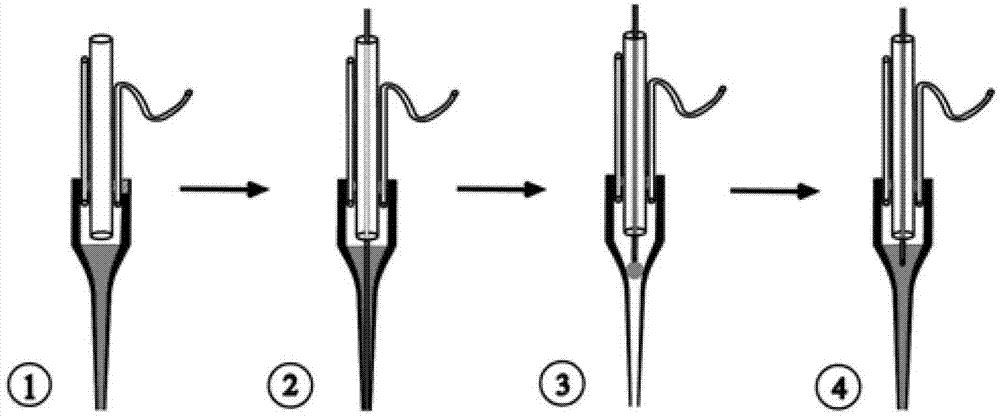

Trace drug delivery and changing device utilizing electroosmosis/pressure technology and application and manufacturing method of trace drug delivery and changing device

InactiveCN103040537BPrecise positioningReduce mistakesVeterinary instrumentsMicroelectrodeGuide tube

The invention relates to a trace drug delivery and changing device utilizing the electroosmosis / pressure technology and an application and manufacturing method of the trace drug delivery and changing device. The device comprises a glass microelectrode, a first PE (polyethylene) tube, a second PE tube and a third PE tube. The glass microelectrode comprises a thick section, a thin section and a neck, wherein the neck is a joint between the thick section and the thin section. The diameters of the first PE tube and the second PE tube are smaller than that of the third PE tube. The first PE tube, the second PE tube and the third PE tube are inserted at openings of the thick section. A gap between the thick section and each of the first PE tube, the second PE tube and the third PE tube is sealed. By the multifunctional trace drug delivery and changing device which is capable of drug delivery and changing, animal anesthesia and supporting of a drug delivery core tube by hands during drug delivery are avoided, positioning errors of traditional drug delivery are avoided, guide tube blocking in traditional drug delivery is eliminated, and trace drug delivery can be performed by selectively utilizing electroosmosis or pressure injection. In addition, the whole device is simple and cheap to manufacture, and more convenient in drug delivery.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

A kind of separated po43- ion selective microelectrode and its preparation method

ActiveCN103868968BContinuous determination of concentrationDetermination of concentrationMaterial analysis by electric/magnetic meansActivated sludgeEpoxy

The invention discloses a discrete PO4<3-> ion selective micro electrode and a preparation method thereof. The micro electrode comprises a tubular conical glass tube, wherein one end of the tubular conical glass tube is a conical tip, and the other end of the tubular conical glass tube is a cylindrical end face; a metal wire in middle wound connection penetrates through the tubular conical glass tube; a cobalt wire is arranged at one end of the metal wire in middle wound connection, and a fine copper wire is arranged at the other end of the metal wire; the cobalt wire and the fine copper wire respectively extend out of the conical end and the cylindrical end face of the tubular conical glass tube; the inner part of the tubular conical glass tube is filled with bismuth alloy coated with the cobalt wire and at the winding end; the cylindrical end face of the tubular conical glass tube is closed by an epoxy resin and is fixed with the fine copper wire. The preparation method comprises the following steps: drawing the tubular conical glass tube, etching and mounting the cobalt wire, filling the bismuth alloy and assembling the micro electrode. The spatial distribution characteristics of concentration of phosphate (comprising metaphosphate) inside activated sludge groups and natural water body sediments can be rapidly and continuously measured.

Owner:陕西省膜分离技术研究院有限公司

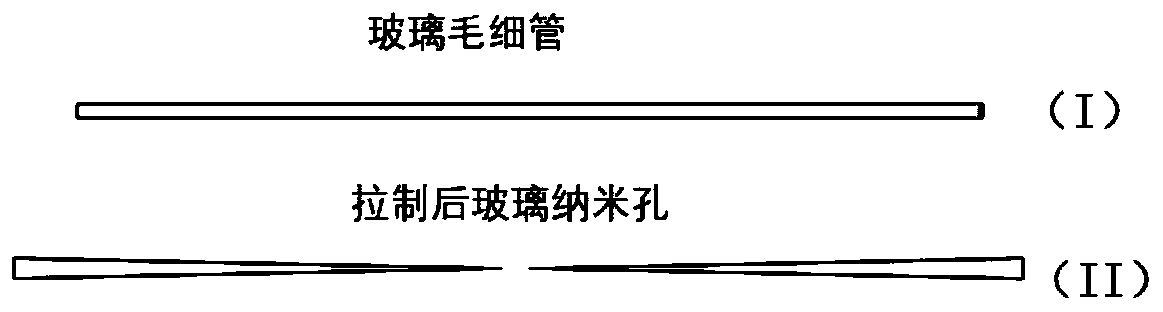

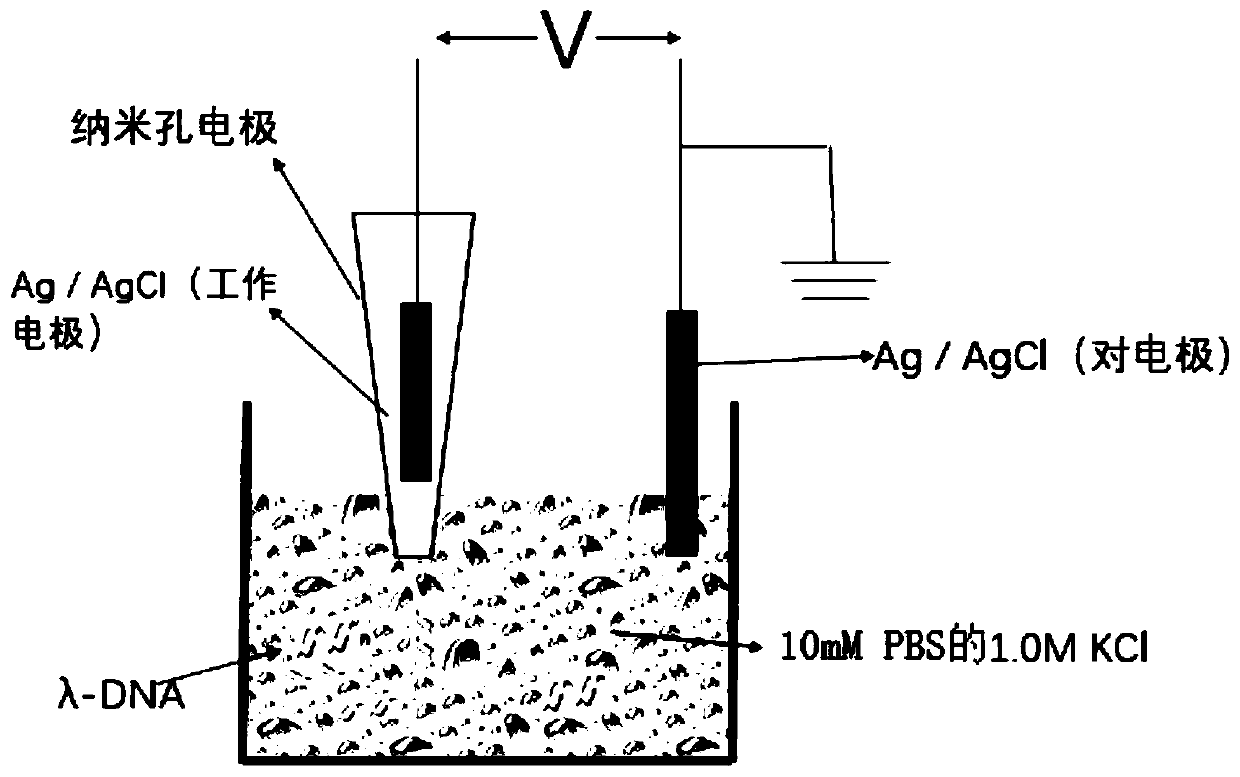

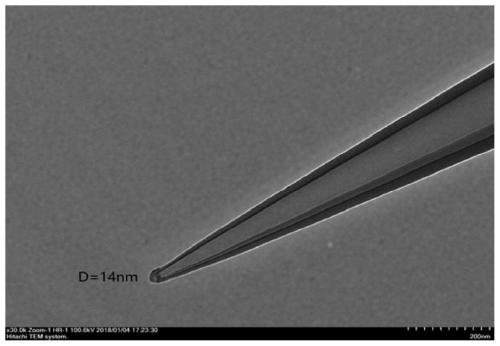

A glass nanopore with a diameter less than 10nm, its preparation method and its application for detecting dna

ActiveCN108996461BOptimizing the drawing processSmall diameterSemi-permeable membranesVolume/mass flow by thermal effectsCapillary TubingNanopore

Owner:ANHUI NORMAL UNIV

Multi-pass cold-drawing plastic deformation pattern prediction method for pure aluminium wires based on ANSYS/LS-dyna

ActiveCN108509666AHigh breaking strengthOptimizing the drawing processDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

The invention discloses a multi-pass cold-drawing plastic deformation pattern prediction method for pure aluminium wires based on ANSYS / LS-dyna. The method mainly comprises the steps that according totechnological parameters of the pure aluminium wires and a mold, an entity model of the wires and the mold is established based on an ANSYS parametric modeling technology; according to a large deformation behavior of the wires in the drawing process, a kinematic hardening material model is selected, and parameters of the material model are determined according to a tensile stress-strain curve ofthe wires in all passes; a loading mode and a boundary condition of a finite element model are determined according to the drawing traction mode and drawing speed of the wires on a drawbench; and last, a defined finite element analysis model is submitted to LS-dyna for calculation, ANSYS is used to post-process a result file, a stress distribution and plastic deformation cloud chart is output, anda stress change curve of the wires in all the passes from the central part to the surface layer is drawn. According to the method, an existing wire simulation method is improved, and calculation efficiency and calculation precision are improved; and compared with a test method, technological parameter verification time is greatly shortened, and design cost is lowered.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

A kind of preparation method of zinc-aluminum alloy welding wire

ActiveCN104772583BControl ingredientHigh surface finishWelding/cutting media/materialsSoldering mediaAdditive ingredientSemi automatic

The invention discloses a preparing method of zinc-aluminum alloy welding wires, and belongs o the technical field of welding wire processing. According to the preparing method of the zinc-aluminum alloy welding wires, various processes such as melting, horizontal continuous casting, cleaning, tangential continuous extrusion with filling soldering flux, rotation forging and pulling are combined for preparing the welding wires. The preparing method has the advantages that the ingredients of the zinc-aluminum alloy can be controlled on line; the tangential continuous rod blank with the advantages of better surface smoothness, roundness and lower production cost is provided; continuous production, low energy consumption, uniform tissue performance and high production efficiency are realized, and the fully automatic / semi-automatic control of the process can be easily realized; the welding flux is compactly pressed, the tissue performance of the welding wires is good, thinner wire blanks with almost infinite length can be obtained, and higher pulling diameter reducing efficiency is realized. The preparing method of the zinc-aluminum alloy welding wires has the characteristics that the integral mechanical property of the welding wires is good, the welding flux loss is little, the production efficiency is high, the yield rate is high, the production automation degree is high, and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing microcrystalline glass fiber from blast furnace slag powder and microcrystalline glass fiber

The invention provides a method for preparing microcrystalline glass fiber from blast furnace slag powder and microcrystalline glass fiber, and belongs to the technical field of glass fiber materials. The method comprises the following steps: melting waste glass to form molten glass; the blast furnace slag powder is fed into the molten glass, so that the blast furnace slag powder can be quickly laid on the liquid surface, the melting of the blast furnace slag powder is promoted, and the feeding mode can provide viscosity reduction time for a mixture formed by the molten glass and the blast furnace slag powder, so that the melting of the blast furnace slag powder in the melting process is further accelerated; then, bubbles and refractory components in the melt are removed through clarification, and the density of the melt is homogenized through homogenization; high-temperature spinning treatment is adopted, so that on one hand, sufficient plasticity of glass ceramic liquid is guaranteed, drawing is facilitated, and on the other hand, fiber breakage or large residual thermal stress caused by rapid cooling in the drawing process is prevented; and finally, heat treatment is performed to eliminate a small amount of internal stress remained in the microcrystalline glass fibers and improve the mechanical properties of the fibers.

Owner:SHAANXI SCI TECH UNIV

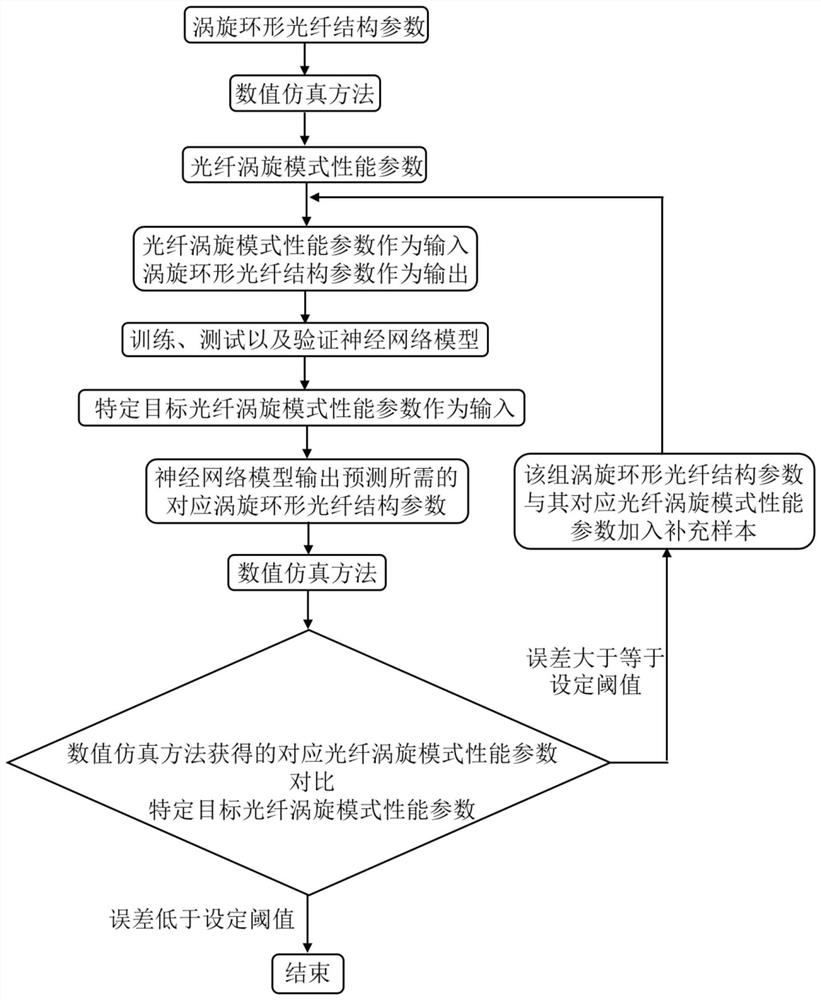

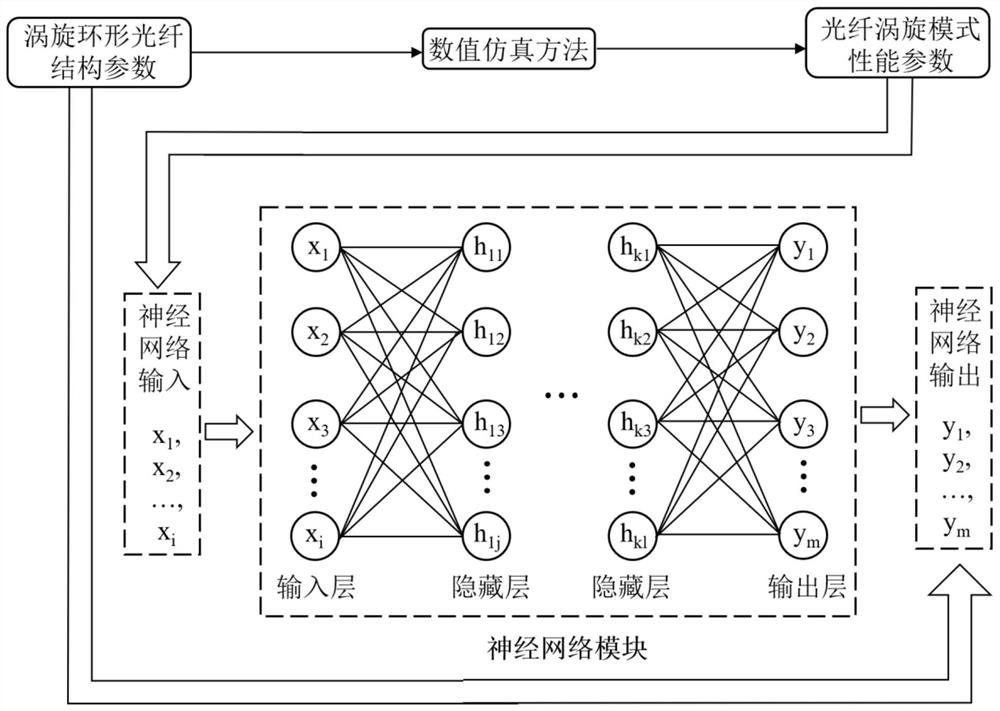

Neural network-based optical fiber vortex mode engineering method

PendingCN113190979AFlexible adjustment of structural parametersBreak through limitationsDesign optimisation/simulationFibre transmissionFiber chromatic dispersionEngineering

The invention discloses an optical fiber vortex mode engineering method based on a neural network, and belongs to the field of optical fiber communication. The optical fiber vortex mode performance parameters are acquired corresponding to the vortex ring optical fiber structure parameters through numerical simulation. A neural network is utilized to construct a complex function relation between optical fiber vortex mode performance parameters and vortex ring optical fiber structure parameters, wherein the optical fiber vortex mode performance parameters serve as input, and the vortex ring optical fiber structure parameters serve as output, thereby training, testing and verifying the neural network model. Finally, the target optical fiber vortex mode performance parameters are inputted into the neural network model to predict required vortex ring optical fiber structure parameters, thereby realizing optical fiber vortex mode engineering based on the neural network. The limitation of a traditional vortex optical fiber design method and the bottleneck of vortex mode regulation and control are broken through, an optical fiber vortex mode project with a brand new thought is provided for similar optical fiber dispersion engineering, the optical fiber vortex mode engineering has a wide application prospect in the field of vortex mode space division multiplexing systems, and the blank of related technical fields is filled.

Owner:HUAZHONG UNIV OF SCI & TECH

Device for making capillary pipe spray interface for co-using liquid chromatography and mass spectra

ActiveCN101382527BIdeal mass spray effectOptimizing the drawing processComponent separationChromatographic separationManufacturing technology

The invention relates to the manufacture of an interface used for the combination of a liquid chromatographic separation system and a mass spectrum, in particular to a manufacturing device of a capillary spray interface used for the combination of liquid chromatogram and the mass spectrum, which comprises a 'U'-shaped bracket, two top ends of the 'U'-shaped bracket are respectively provided with a coaxial transverse sliding chute, hollow adjusting screw rods are respectively arranged in the sliding chutes and can transversely slide along the horizontal direction in the sliding chutes; the inner and outer surfaces of the inner side of the adjusting screw rod are respectively provided with internal screw threads and external screw threads, a PEEK head is screwed on the front end of the adjusting screw rod through the internal screw threads and internally passed by a polytetrafluoroethylene tube or a PEEK tube, an adjusting screw nut is arranged on the external screw threads; the interior of the 'U'-shaped bracket is provided with a high-temperature flame lamp; wherein, the inner chamber of the polytetrafluoroethylene tube or the PEEK tube is used for being sheathed with a quartz capillary. The device has simple manufacturing technology, uses raw materials with low price, and can comparatively and conveniently manufacture ideal mass spectrum spray interfaces with high mission success rate and good uniformity.

Owner:徐州脉析医疗技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com