A copper wire drawing device for cable production and its drawing method

A copper wire and cable technology, applied in the manufacture of cables/conductors, used to reduce the size of conductors/cables, circuits, etc. Damage degree, ensure stable use, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

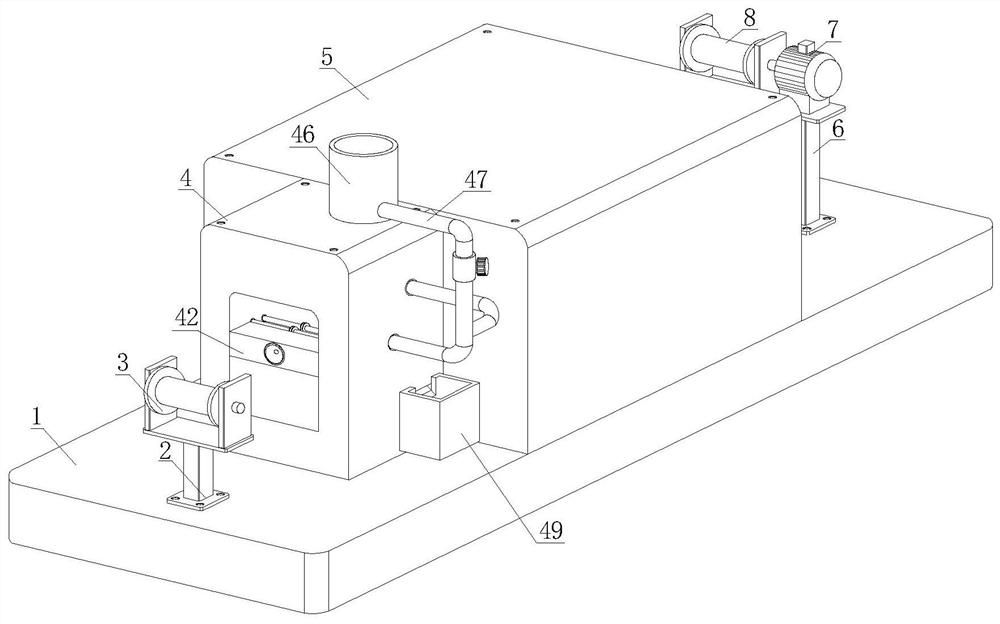

[0036] see figure 1 , a copper wire drawing device for cable production, including a pay-off reel 3, a lubricating mechanism 4, a drawing host 5, a drive motor 7 and a take-up reel 8, and a support base 1, a first support frame 2 and a second Support frame 6, the first support frame 2 is installed on the upper end side of the support base 1, the pay-off reel 3 is arranged on the upper end of the first support frame 2, and the upper end side of the support base 1 close to the pay-off reel 3 is provided with a lubrication mechanism 4. The lubricating mechanism 4 is connected and communicated with the inlet end of the drawing host 5, the second support frame 6 is installed on the other side of the upper end of the support base 1, the drive motor 7 is installed on the upper end side of the second support frame 6, and the wire is taken up. The coil 8 is arranged on the other side of the upper end of the second support frame 6 .

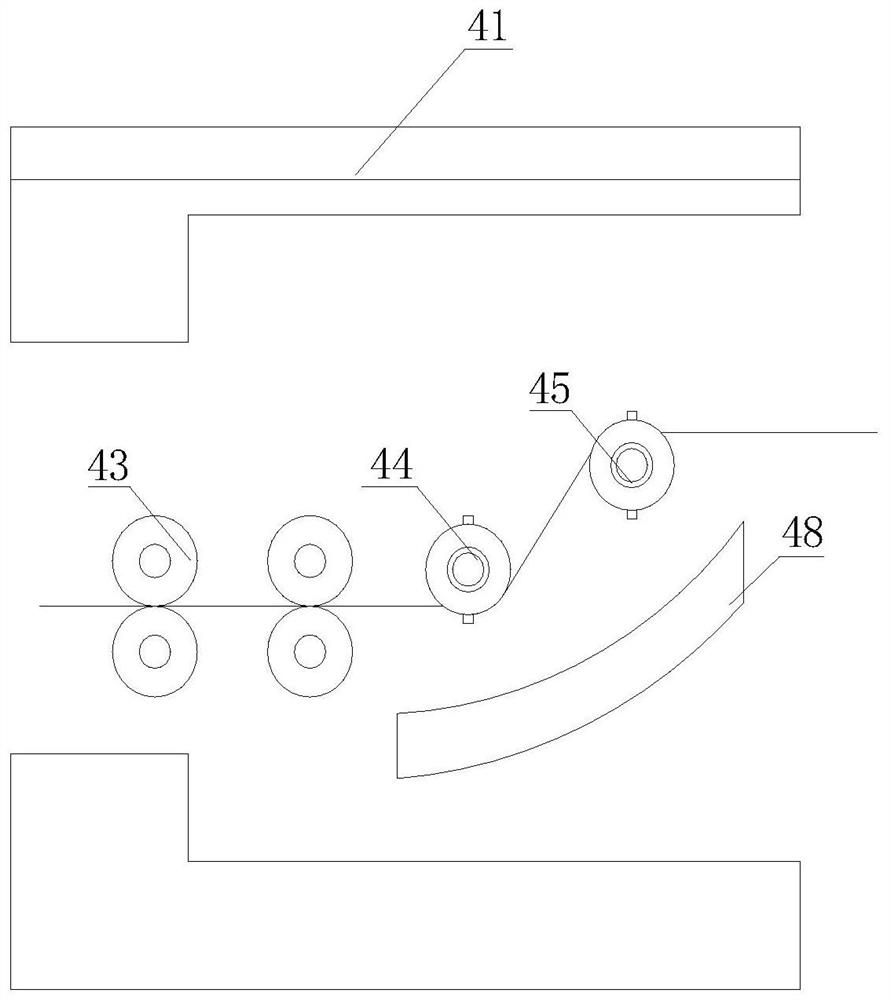

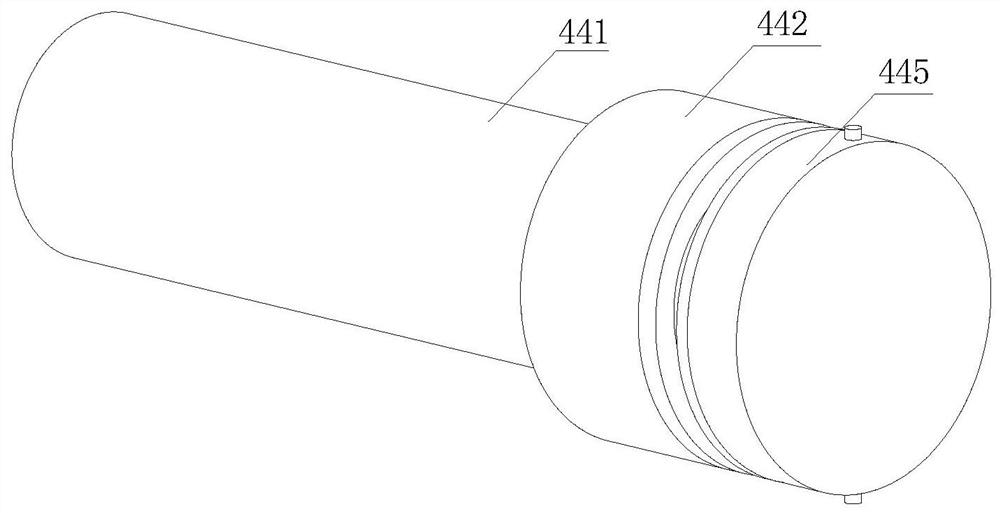

[0037] see figure 2 , the lubrication mechanism 4...

Embodiment 2

[0047] see figure 1 , a copper wire drawing device for cable production, including a pay-off reel 3, a lubricating mechanism 4, a drawing host 5, a drive motor 7 and a take-up reel 8, and a support base 1, a first support frame 2 and a second Support frame 6, the first support frame 2 is installed on the upper end side of the support base 1, the pay-off reel 3 is arranged on the upper end of the first support frame 2, and the upper end side of the support base 1 close to the pay-off reel 3 is provided with a lubrication mechanism 4. The lubricating mechanism 4 is connected and communicated with the inlet end of the drawing host 5, the second support frame 6 is installed on the other side of the upper end of the support base 1, the drive motor 7 is installed on the upper end side of the second support frame 6, and the wire is taken up. The coil 8 is arranged on the other side of the upper end of the second support frame 6 .

[0048] see Figure 1-2 , the lubrication mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com