A glass nanopore with a diameter less than 10nm, its preparation method and its application for detecting dna

A nanopore and glass technology, applied in the field of preparation and detection of DNA, in the field of glass nanopores, can solve the problems of irreversibility and high experimental cost, preventing practical use, inapplicability, etc., to improve the DNA transport signal and signal-to-noise ratio. , the effect of reducing the concentration, the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

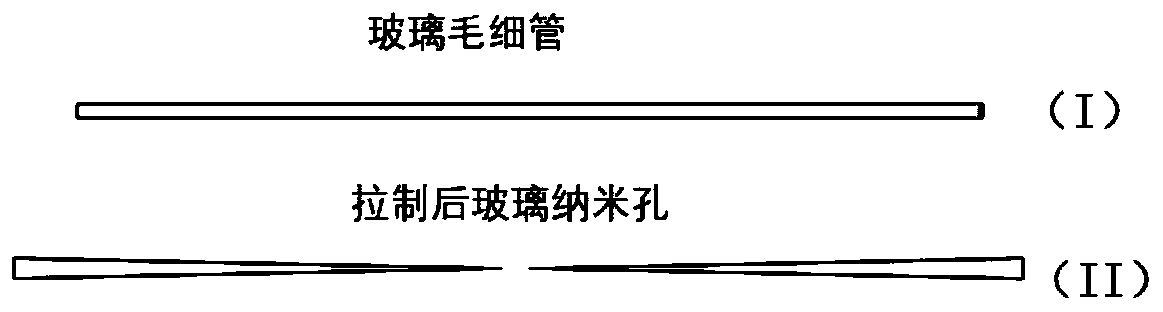

[0040] A method for preparing a glass nanopore with a diameter less than 10nm, comprising the following steps:

[0041] 1) Glass capillary inner diameter: 0.7mm; outer diameter: 1mm; length 10cm; purchased from Sutter Company; install the glass capillary on the P-2000 laser microelectrode puller, stabilize the two moving rods with aluminum fixtures, and pass the following Heating program: heating=550°C, filament=3, speed=99m / s, delay=20ms, pull=50N, heating program is applied for 40 seconds, then 20 seconds cooling period, the above-mentioned heating and cooling process is repeated 3-4 times to obtain Microporous preforms.

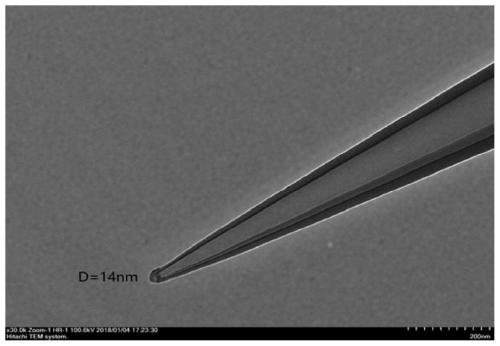

[0042] 2) Remove the fixture from the puller, and perform the following pulling program to pull the preform into two glass nanopores with a diameter less than 10 nm: Pulling program parameters: heating = 660 ° C, filament = 1, speed = 60m / s, delay = 165ms, pull = 225-230N, pull off, that is, two glass nanopores with a diameter of less than 10nm are obtain...

Embodiment 2

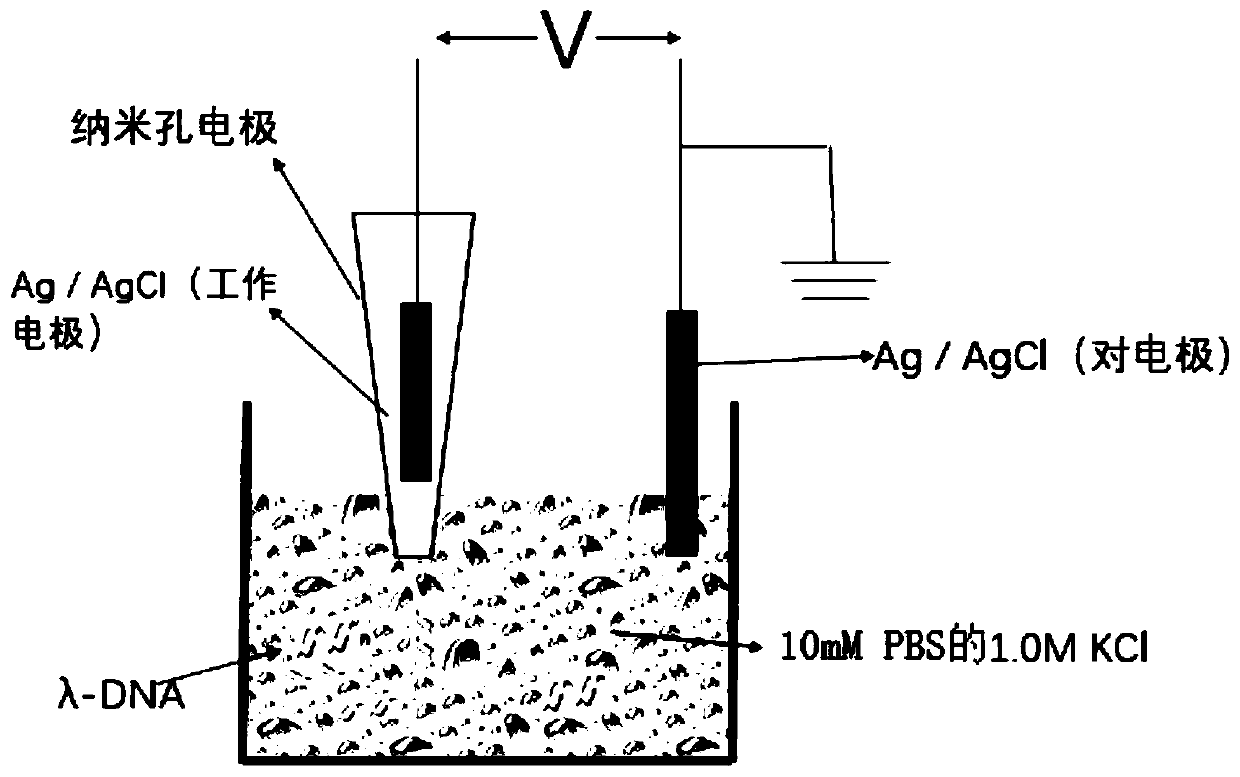

[0052] The application of a glass nanopore with a diameter less than 10nm prepared in Example 1 for detecting DNA, the specific method is:

[0053] Chemical experiments such as cyclic voltammetry (CV) and chronoamperometry (I-t) were performed on a CHI 660C (Shanghai Huachen) electrochemical workstation using a two-electrode system. By inserting the Ag / AgCl electrode into the prepared nanopore tail as the working electrode; the counter electrode is also an Ag / AgCl electrode, immersed in the solution (1.0M KCl in 10mM PBS, pH7.4) outside the nanopore. Please refer to the illustration for details figure 2 . Cyclic voltammetry curves CV and current-time (I-t) curves were amplified and collected by using a current amplifier (Axon 200b, Axon Instrument, Forest City, USA) and Shanghai Chenhua Electrochemical Workstation. The detected DNA is λ-DNA (pBR322-DNA) purchased from Shanghai Sangon Bioengineering Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com