Aluminum-clad steel wire and its preparation method

A technology of aluminum-clad steel wire and steel wire, which is applied in the field of aluminum-clad steel wire and its preparation, can solve the problem that the tensile strength cannot reach 2000MPa, and achieve the effect of optimizing the drawing process, simple steps, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

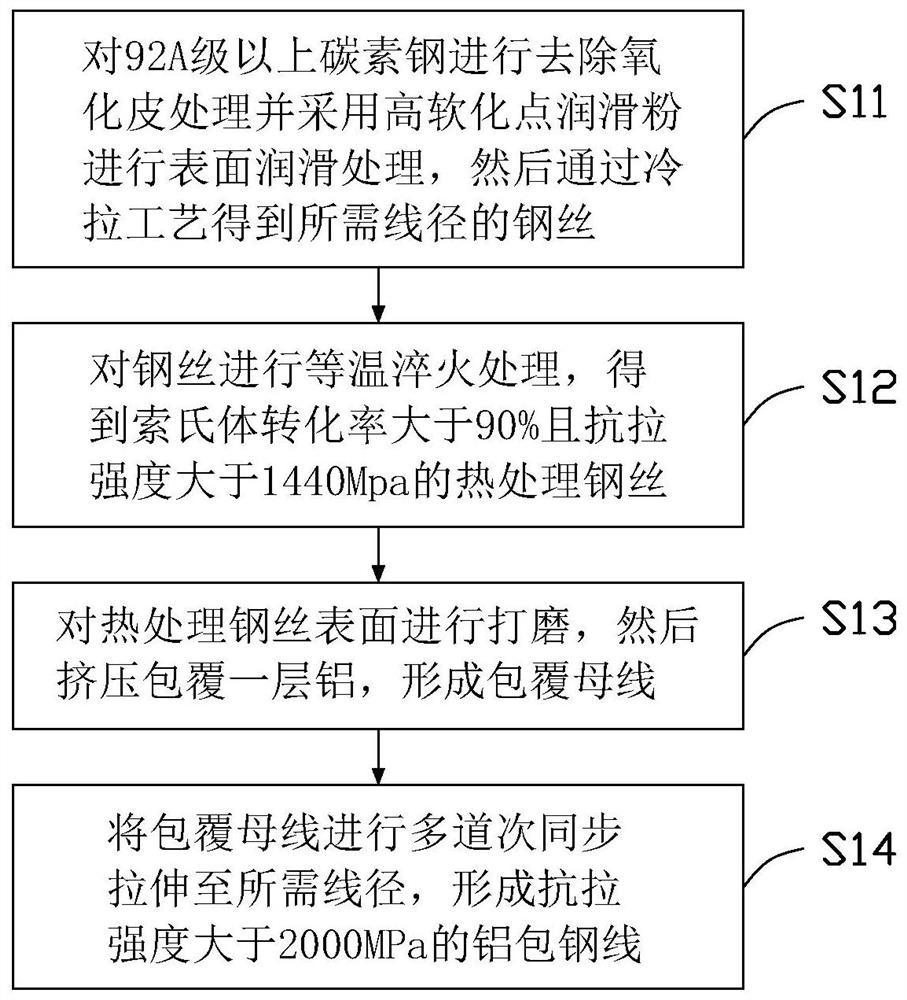

[0023] see figure 1 , figure 1 It is a schematic flow chart of a method for preparing an aluminum-clad steel wire in an embodiment of the present invention, which specifically includes the following steps:

[0024] Step S11, performing mechanical peeling, abrasive belt grinding and surface lubrication on the carbon steel above grade 92A in sequence, and then obtaining a steel wire with a required wire diameter through a cold drawing process;

[0025] Step S12, performing continuous austempering on the steel wire to obtain a heat-treated steel wire with a sorbite conversion rate greater than 90% and a tensile strength greater than 1440Mpa;

[0026] Step S13, grinding the surface of the heat-treated steel wire, and then extruding and coating a layer of aluminum to form a coated bus bar;

[0027] In step S14, the clad busbar is stretched synchronously for multiple times to the required wire diameter to form an aluminum clad steel wire with a tensile strength greater than 2000 M...

Embodiment 1

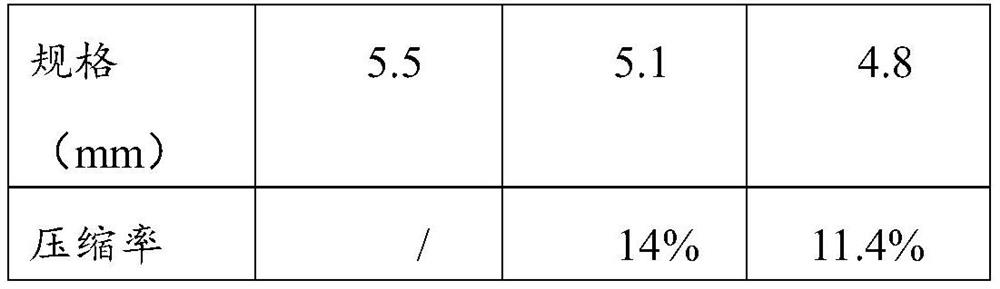

[0035] Will the specification be The AS92A high-carbon steel hot-rolled wire rod passes through the mechanical peeling device, the abrasive belt grinding device, and the coating lubrication device in sequence, and is cold-drawn for 2 passes until the wire diameter required by the process is high carbon steel wire. The drawing speed is controlled at 100m / min, and the line temperature is controlled below 120°C. The coating is lubricated with high softening point lubricating powder, and the pass compression rate is:

[0036]

[0037] Will The high-carbon steel wire is quenched in a lead bath, the wire temperature is controlled at 910°C, the lead bath temperature is at 550°C, the DV value is at 62, the sorbite conversion rate is greater than 90%, and the tensile strength of the steel wire after heat treatment is greater than 1500MPa;

[0038] after heat treatment The surface of the steel wire is polished by multiple groups of rotary abrasive belt polishing machines, the ...

Embodiment 2

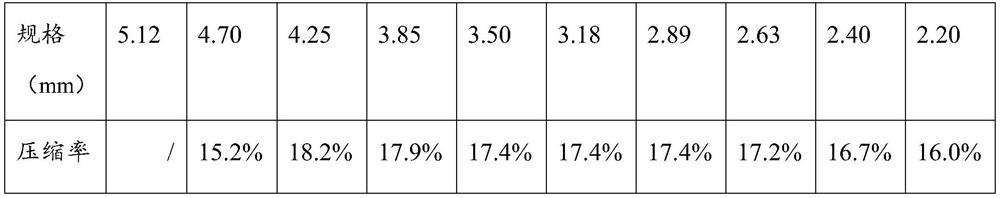

[0043] Will the specification be The AS92B high-carbon steel hot-rolled wire rod passes through the mechanical peeling device, the abrasive belt grinding device, and the coating lubrication device in sequence, and is cold-drawn for 2 passes until the wire diameter required by the process is high carbon steel wire. The drawing speed is controlled at 100m / min, and the line temperature is controlled below 120°C. The coating is lubricated with high softening point lubricating powder, and the pass compression rate is:

[0044]

[0045] Will The high-carbon steel wire is quenched in a lead bath, the wire temperature is controlled at 920°C, the lead bath temperature is at 545°C, the DV value is at 62, the sorbite conversion rate is greater than 90%, and the tensile strength of the steel wire after heat treatment is greater than 1550MPa;

[0046] after heat treatment The surface of the steel wire is polished by multiple groups of rotary abrasive belt polishing machines, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com