Laminating base plate for boring and preparing method thereof

A backing plate and urea-formaldehyde resin technology, which is applied in the field of PCB processing and manufacturing, can solve the problems of cost reduction, the backing plate used for drilling cannot meet the requirements of small-diameter drilling at the same time, etc., and achieves high market competitiveness, low cost, and warpage prevention. unusual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention provides a laminated backing plate for drilling and a preparation method thereof. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

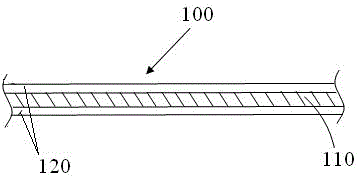

[0016] The invention provides a method for preparing a laminated backing plate for drilling, the method is as follows: the laminated backing plate for drilling is made of wood pulp paper impregnated with phenolic resin and kraft paper impregnated with urea-formaldehyde resin or modified urea-formaldehyde resin. The inner paper is laminated and pressed.

[0017] When the PCB is drilled, the drilling depth layer of the drilling needle on the backing plate of the present invention is thermally stable, low in moisture absorption, and suitable for flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com