Manufacturing method and application of non-reproducible perovskite fluorescent anti-counterfeit label

An anti-counterfeiting label and a production method technology are applied in the production field of perovskite fluorescent anti-counterfeiting labels, which can solve the problems of slow comparison speed, easy cloning of pattern details, cost, and difficulty in identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

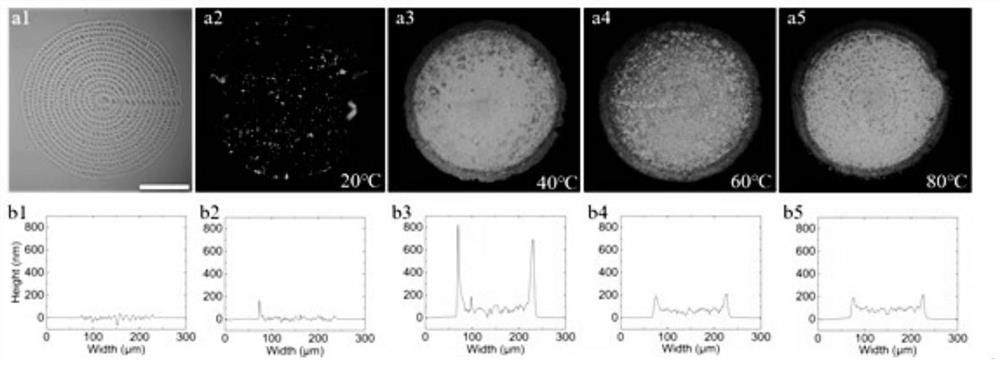

[0047] Example 1: Verifying the Effect of Temperature on Pattern Shape Profile

[0048] A method for making an irreproducible perovskite fluorescent anti-counterfeiting label, comprising the steps of:

[0049] Step 1), preparing a substrate with a patterned lyophilic array: using a glass sheet as a substrate, plasma (plasma cleaning equipment) cleans the surface of the substrate, and evaporates a layer of perfluorooctyltriethoxysilane on the cleaned substrate surface lyophobic treatment, followed by nanosecond UV laser etching to destroy the lyophobic surface, exposing patterned hydrophilic regions (e.g. figure 1 shown in a1), obtain a substrate with a patterned hydrophilic-lyophobic array;

[0050] Step 2), preparation of the precursor droplet array substrate: CsBr and PbBr 2 At the same time, it was dissolved in DMSO (dimethyl sulfoxide) solvent to configure a 0.1M perovskite precursor, and then use a pipette gun to take out 10 μL of the precursor solution and place it in ...

Embodiment 2

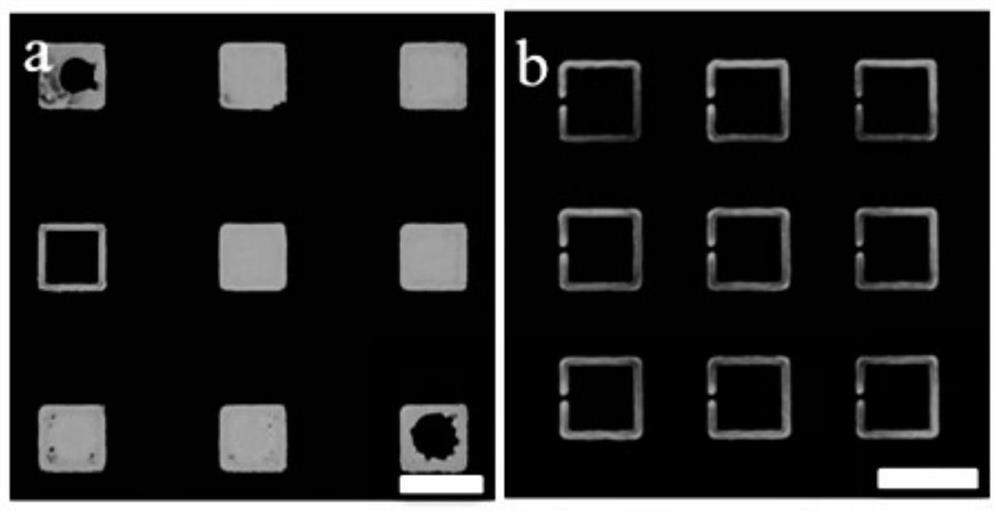

[0053] Embodiment 2: Verify the method for preparing hollowed-out patterns

[0054] A method for making an irreproducible perovskite fluorescent anti-counterfeiting label, comprising the steps of:

[0055] Step 1), preparing a substrate with a patterned lyophilic and lyophobic array: use a glass sheet as the substrate, clean the surface of the substrate with plasma, and evaporate a layer of perfluorooctyltriethoxysilane on the cleaned substrate for surface lyophobic treatment , and then use nanosecond ultraviolet laser etching to destroy the lyophobic surface, exposing the patterned hydrophilic region, and obtaining a substrate with a patterned lyophobic array; the set pattern is a ring line, and the ring line of the control group is fully closed ( Such as figure 2 a), a small gap is set on the circular line of the test group (such as figure 2 b).

[0056] Step 2), with embodiment 1.

[0057] Step 3), heating the substrate to obtain a perovskite fluorescent anti-counterf...

Embodiment 3

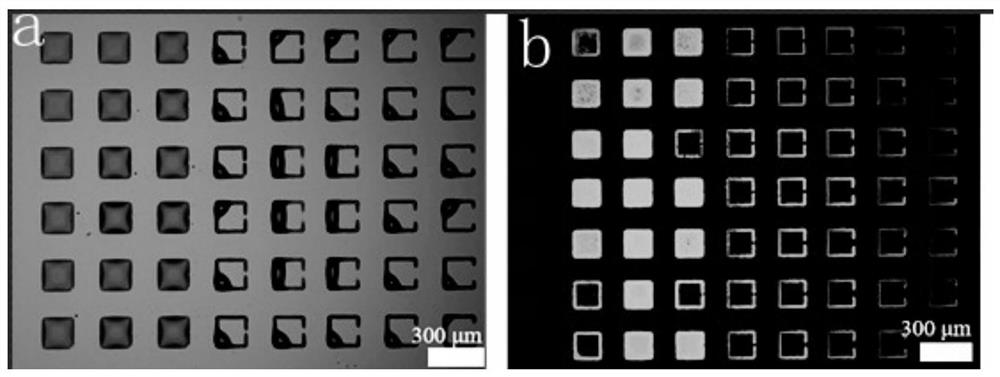

[0060] Embodiment 3: prepare the solid pattern of different shape profile

[0061] Step 1), preparing a substrate with a patterned lyophilic and lyophobic array: use a glass sheet as the substrate, clean the surface of the substrate with plasma, and evaporate a layer of perfluorooctyltriethoxysilane on the cleaned substrate for surface lyophobic treatment , and then use nanosecond ultraviolet laser etching to destroy the lyophobic surface, exposing the patterned hydrophilic region, and obtaining a substrate with a patterned lyophilic array; designing 60 different solid patterns;

[0062] Step 2), with embodiment 1.

[0063] Step 3), heating the substrate to obtain a perovskite fluorescent anti-counterfeiting label: heating the patterned precursor droplet array substrate obtained in step 2) at 60°C.

[0064] Experimental results: if Figure 4 As shown, it can be seen that each pattern has a unique topographical texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com