A method of manufacturing a multilayer circuit board and the multilayer circuit board

A multi-layer circuit board, circuit board technology, applied in the direction of multi-layer circuit manufacturing, circuit, printed circuit, etc., can solve the problems of not completely avoiding pad connection failure, not fully compressing conductive paste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] [Multilayer PCB]

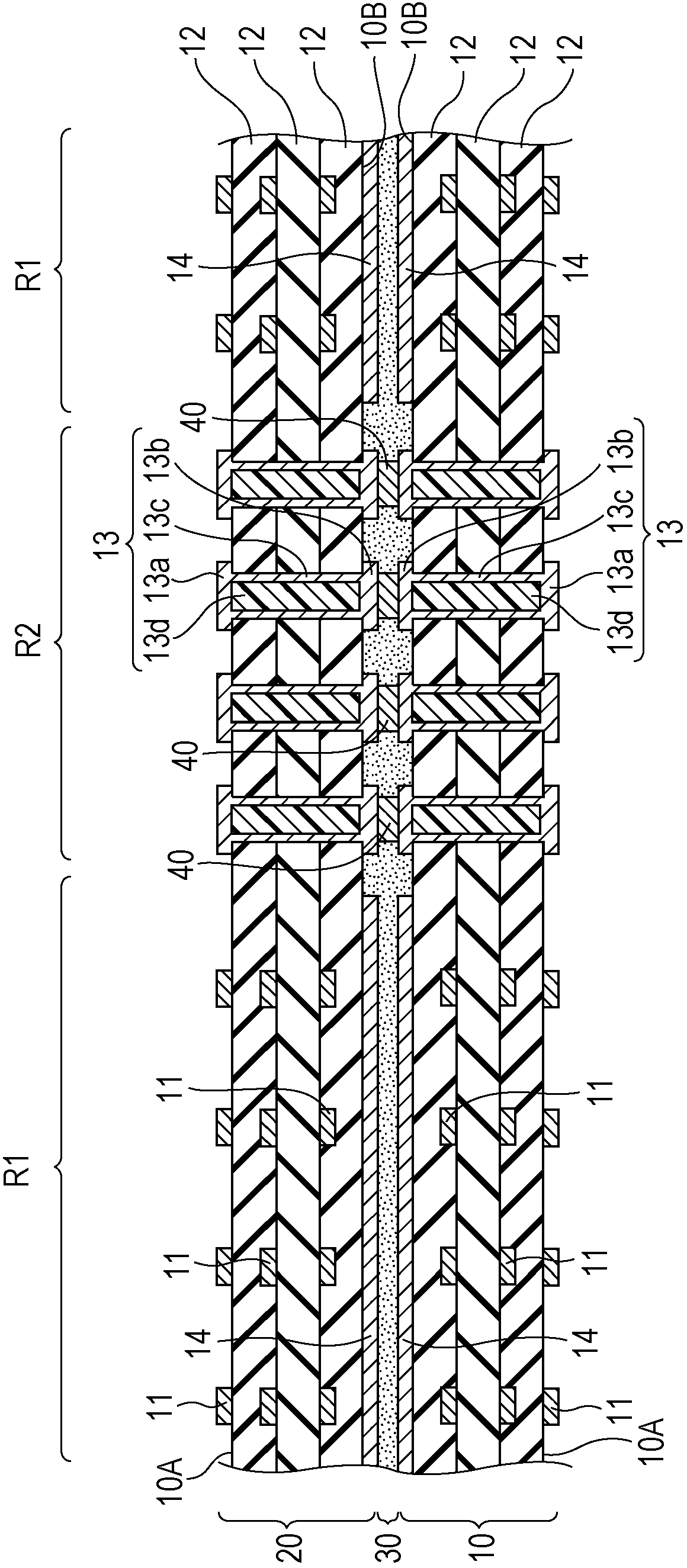

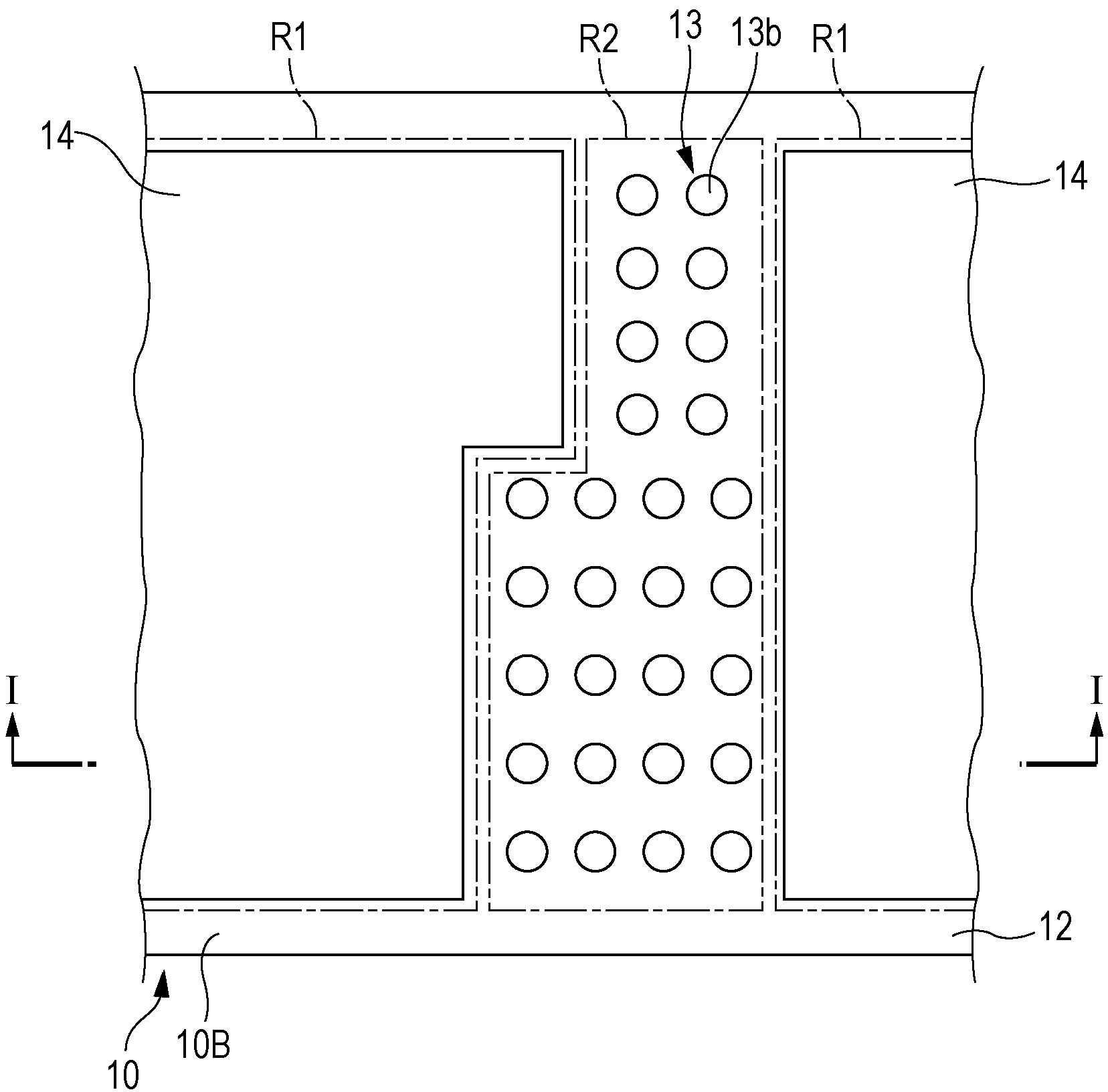

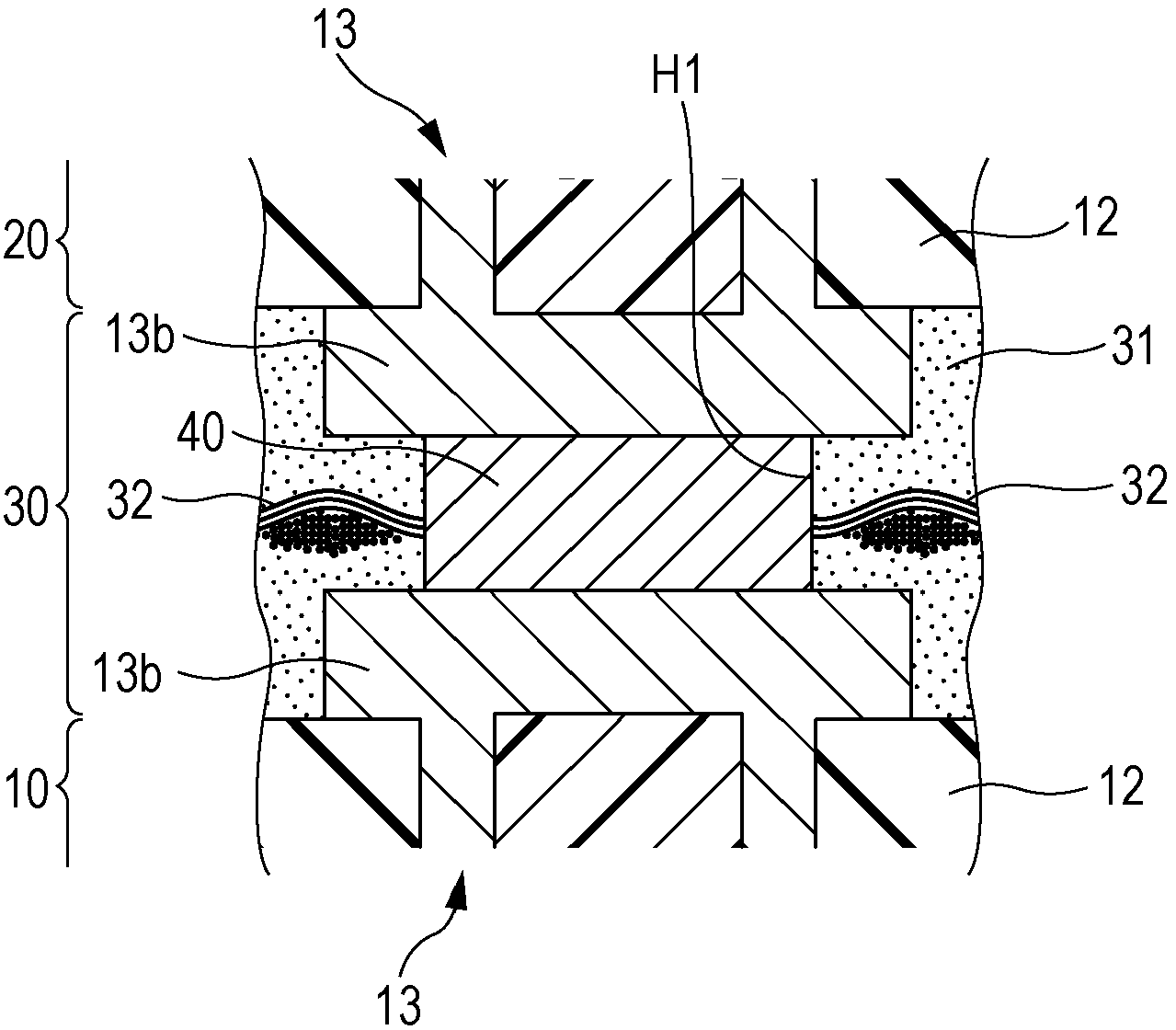

[0026] The following will refer to figure 1 , figure 2 , Figure 3A and Figure 3B Describe the construction of a multilayer circuit board.

[0027] figure 1 is a cross-sectional view of a multilayer circuit board according to one embodiment. figure 2 is a plan view of the first circuit board 10 according to one embodiment, which depicts figure 1 In the second surface 10B of the first circuit board 10, the intermediate insulating layer 30 is bonded to the second surface 10B. To be careful of, figure 1 depicts along the figure 2 The cross section obtained in line I-I.

[0028] Such as figure 1 and figure 2 As shown, the multilayer circuit board includes a first circuit board 10, a second circuit board 20, an intermediate insulating layer 30 for bonding the first circuit board 10 and the second circuit board 20 to each other, and an intermediate insulating layer 30 for bonding the first circuit board 10 to each other. The pad connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com