Method for preparation of artificial laminated board and the regulating and transport unit thereof

A manufacturing method and a technology of a conveying device are applied in the field of decorative materials, which can solve the problems of difficulty in realizing industrialized production, dislocation of wood grain patterns, low yield of simulated MF boards, etc., and achieve the effect of realistic three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

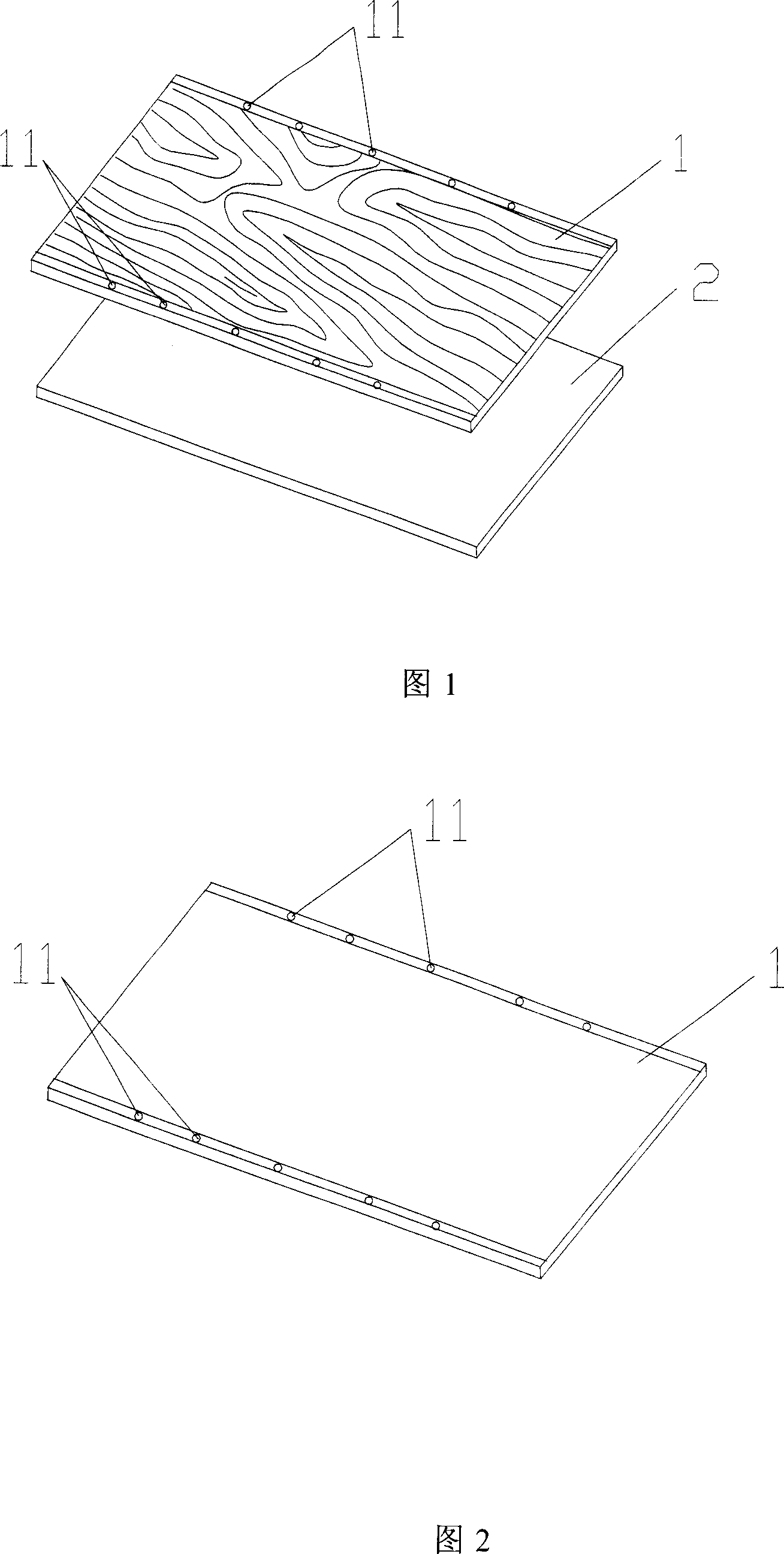

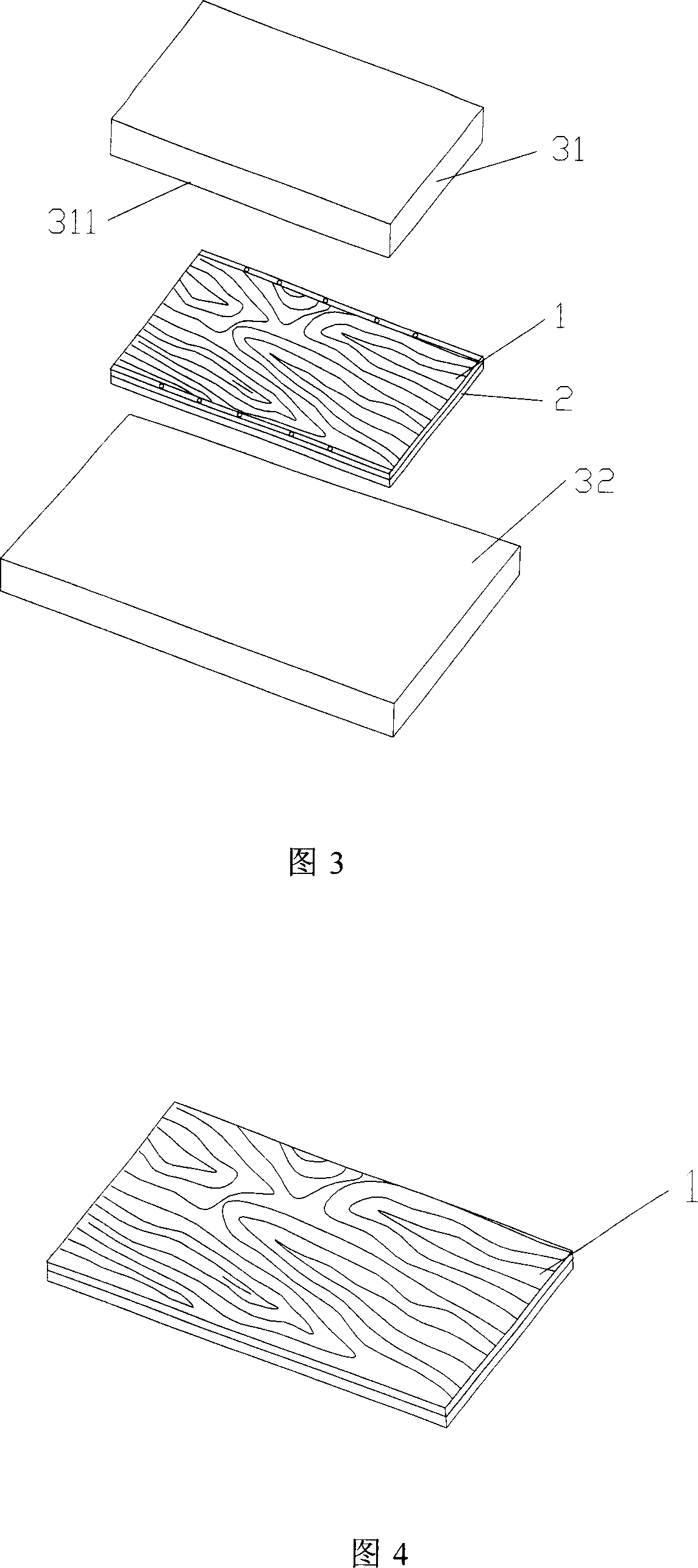

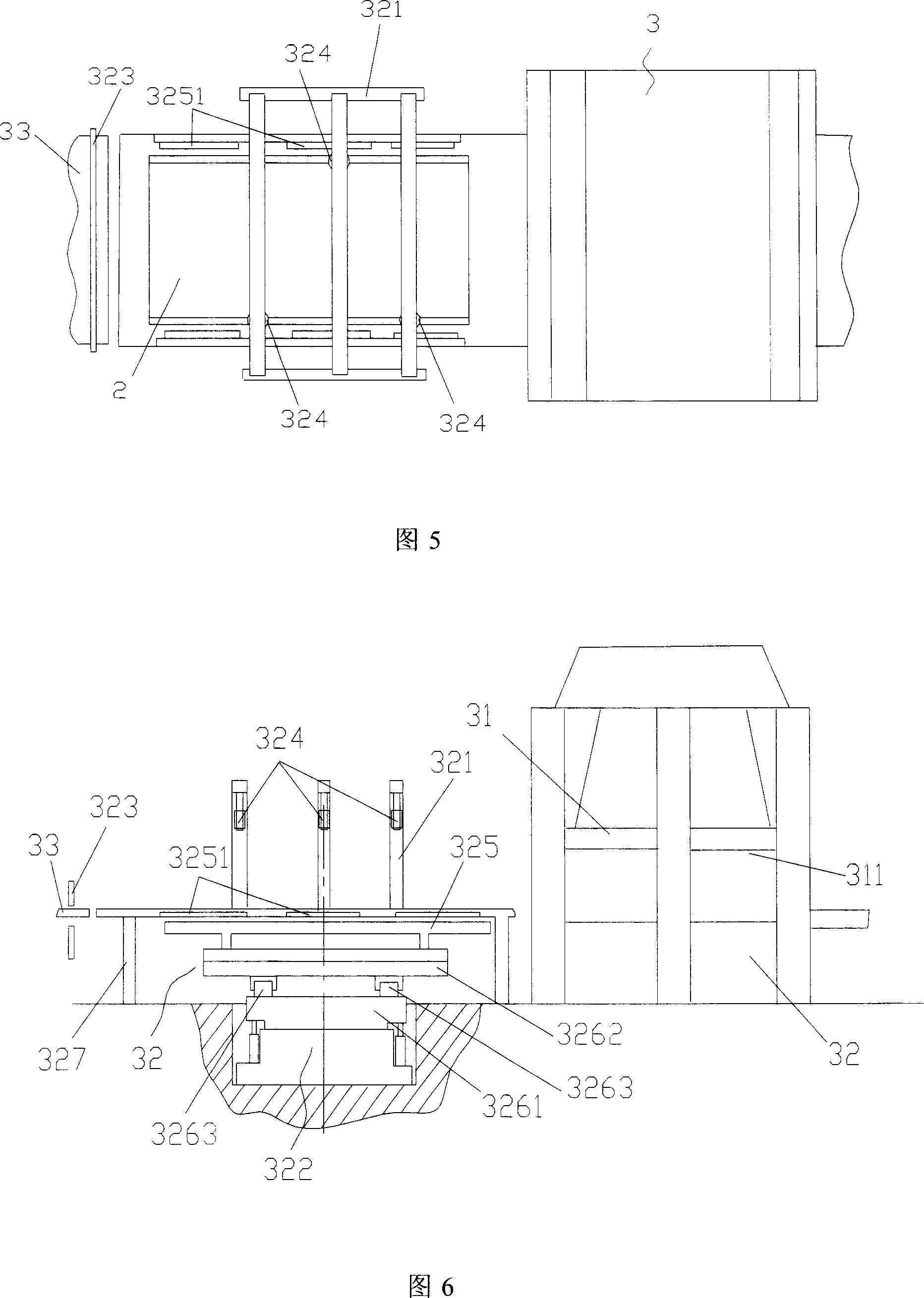

[0044] The implementation steps of the manufacturing method of the present invention will be described through specific examples below with reference to FIG. 1 , FIG. 2 , FIG. 3 , FIG. 4 , FIG. 5 and FIG. 6 .

[0045] First, a patterned overlay paper 1 soaked with melamine resin and a plain board 2 are obtained. The plain board 2 can be a commonly used substrate in the field. The overlay paper 1 is provided with a overlay paper base point 11, the overlay paper base point 11 is a visible point on the surface of the overlay paper 1, and the shape of the overlay paper base point 11 is centrosymmetric. In this embodiment, it is a dot, preferably, the diameter of the dot is less than 3 cm. The base point 11 of the overlay paper is used to express the relative position of the pattern on the overlay paper 1 .

[0046] The distribution positions of the overlay paper base point 11 on the overlay paper 1 are selected on the longitudinal two edges of the overlay paper 1, thereby not des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com