Three-dimensional transversely-wrinkled fuzzing towel and weaving process thereof

A wool towel, three-dimensional technology, applied in the direction of textiles and papermaking, fabrics, textiles, etc., can solve the problems of reducing the efficiency of manufacturers, increasing the burden on consumers, not prominent visual effects, etc., to achieve a more lively form of expression, pattern and The effect of the organization being more novel and highlighting the substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

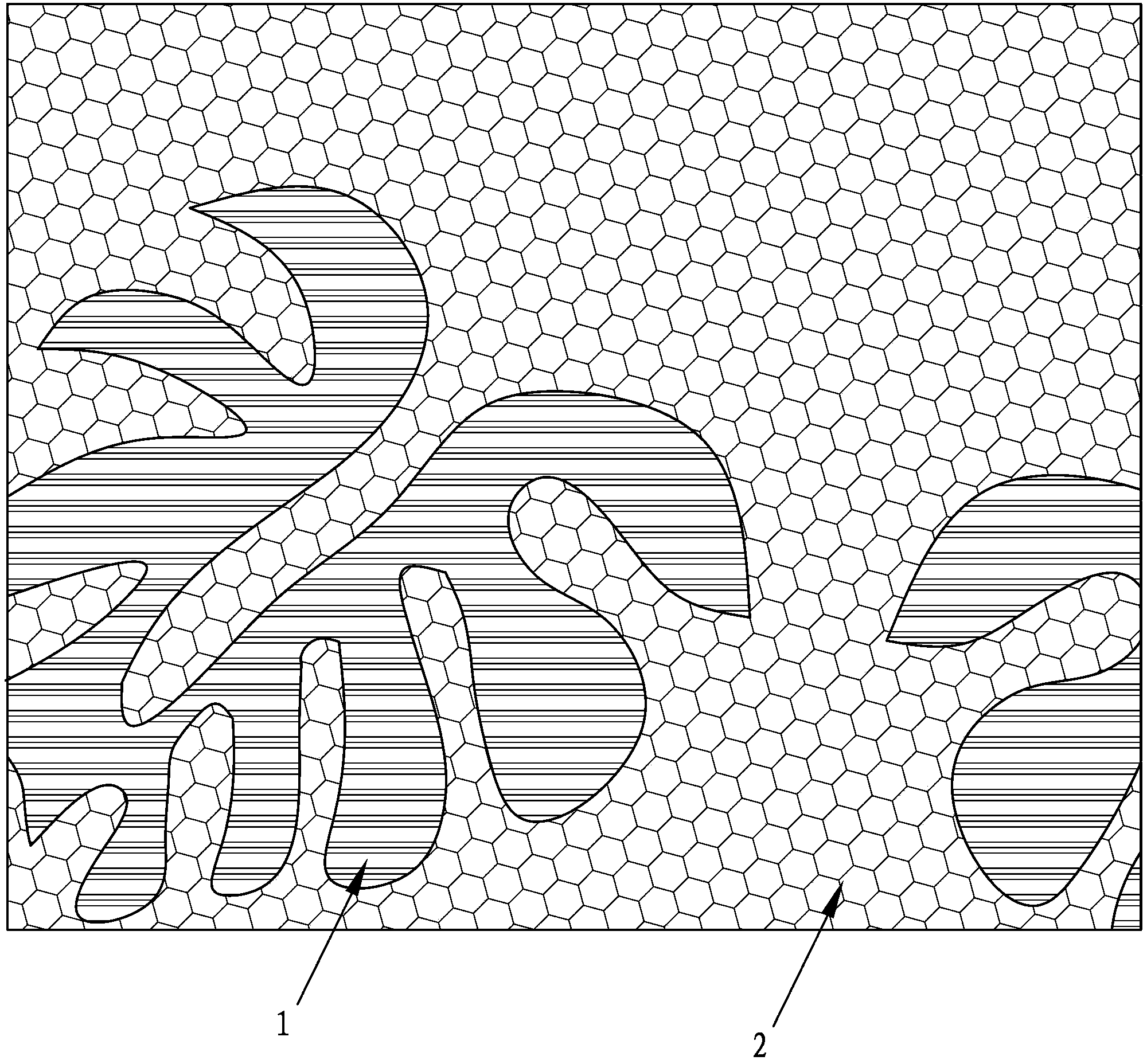

[0038] The weaving process of the three-dimensional horizontal wrinkled pile towel, the wool warp of the jacquard pattern part of the towel is interwoven with the ground warp and the weft yarn to form a piece of plain cloth with a density of 70 weft / cm, and the Swiss Sulzer G6200 satin The ground warp tension torsion bar of the rapier loom is twisted, and the twist value is adjusted to 55 degrees, the wool warp tension torsion bar torsional value is adjusted to 40 degrees, the speed is adjusted to 355 rpm, and 19 wefts are used for wrinkling. Its own density and the tension of the satin loom gather 19 weft yarns to form multiple three-dimensional horizontal wrinkles, that is, through density and tension, the high-density flat cloth is gathered into multiple horizontal wrinkles, and multiple horizontal wrinkles constitute three-dimensional horizontal wrinkles. Wrinkle tissue forms a jacquard pattern; the wool warp of the surrounding part of the jacquard pattern is interwoven wit...

Embodiment 2

[0043] The weaving process of the three-dimensional horizontal wrinkled pile towel, the wool warp of the jacquard pattern part of the towel is interwoven with the ground warp and the weft yarn to form a piece of plain cloth, the density of the plain cloth is 65 weft / cm, and the Swiss Sulzer G6300 satin The ground warp tension torsion bar of the rapier loom is twisted, and the torsion value is adjusted to 50 degrees, the wool warp tension torsion bar torsional value is adjusted to 30 degrees, the speed is adjusted to 350 rpm, and 3 wefts are used for wrinkling. The density of itself and the tension of the satin loom gather the three weft yarns to form multiple three-dimensional horizontal wrinkles; the wool warp, ground warp, and weft yarns around the jacquard pattern are interwoven to form piles, and the wool warp, ground warp, and weft yarn The loops formed by interweaving are distributed around the jacquard pattern formed by the three-dimensional horizontal wrinkle tissue to ...

Embodiment 3

[0047] The weaving process of the three-dimensional horizontal wrinkled pile towel, the wool warp of the towel jacquard pattern part is interwoven with the ground warp and the weft yarn to form a section of plain cloth, the density of the plain cloth is 75 weft / cm, and the Lenado rapier loom The ground warp tension torsion bar is twisted, the torsion value is adjusted to 60 degrees, the wool warp tension torsion bar torsional value is adjusted to 50 degrees, the vehicle speed is adjusted to 360 rpm, and 30 wefts are used for wrinkling. With the help of the density of the flat cloth itself With the tension of the satin loom, 30 weft yarns are concentrated to form multiple three-dimensional horizontal folds; the wool warp, ground warp and weft yarns of the surrounding parts of the jacquard pattern are interwoven to form piles, and the wool warp, ground warp and weft yarns are interwoven to form loops. The loops are distributed around the jacquard pattern formed by the three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com