Method for preparing decorative tablet or decorative cloth with solid pattern

A technology of three-dimensional patterns and production methods, which is applied in chemical instruments and methods, decorative arts, special decorative structures, etc., and can solve problems such as high processing costs, damage, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

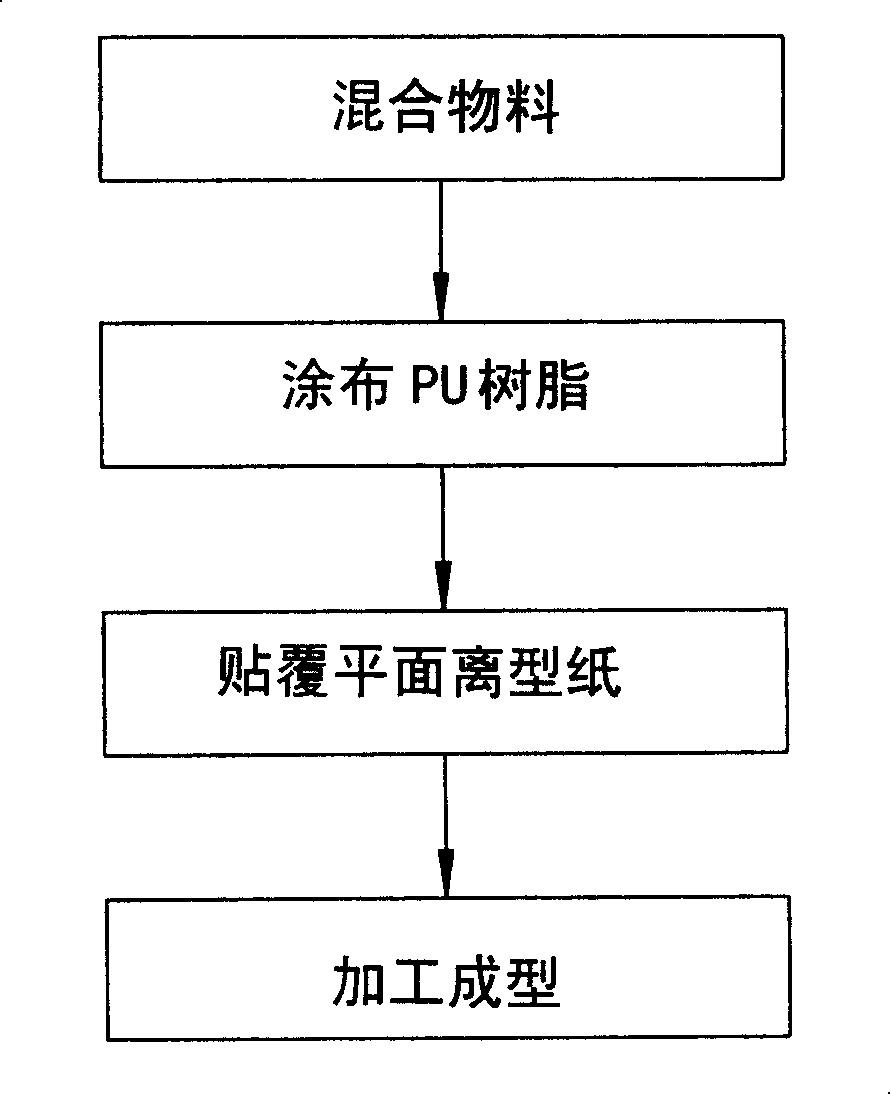

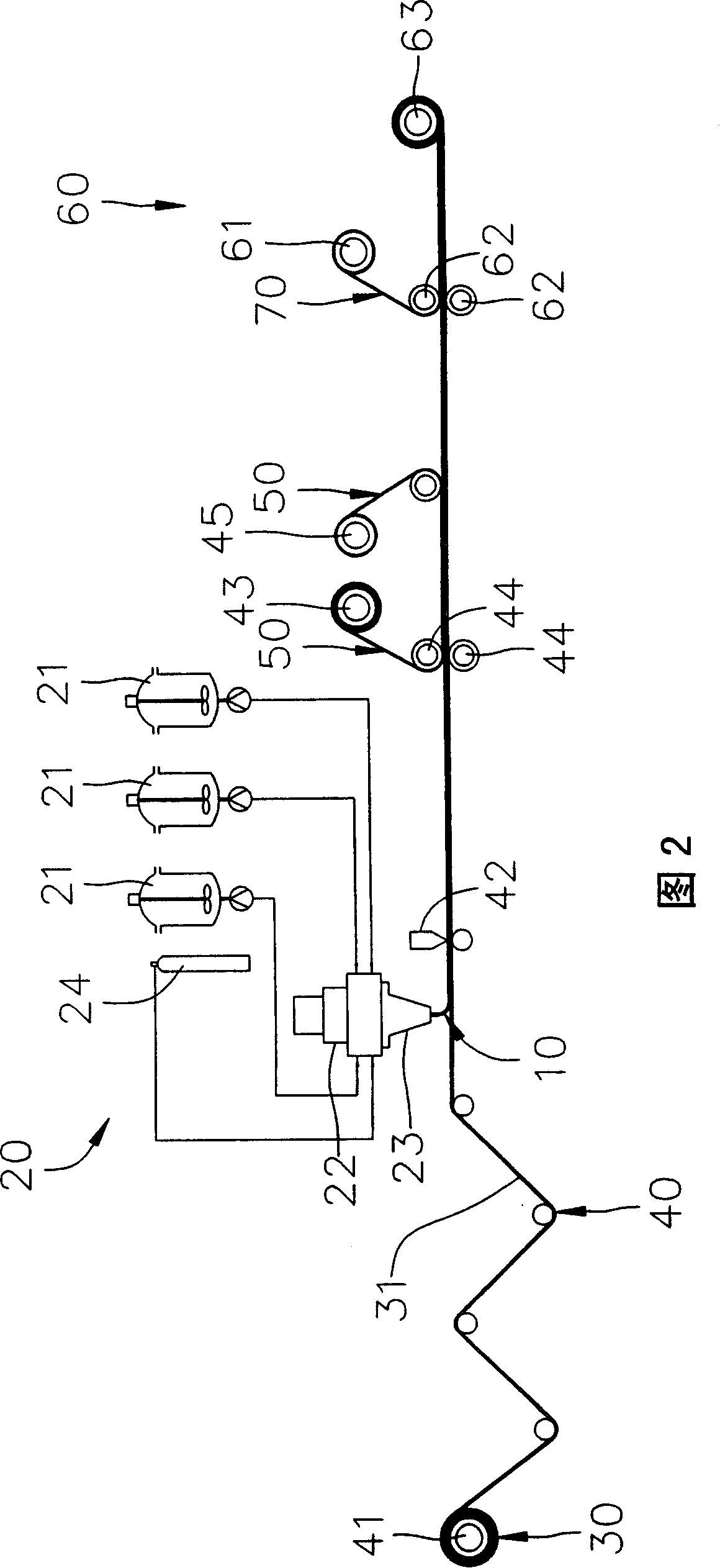

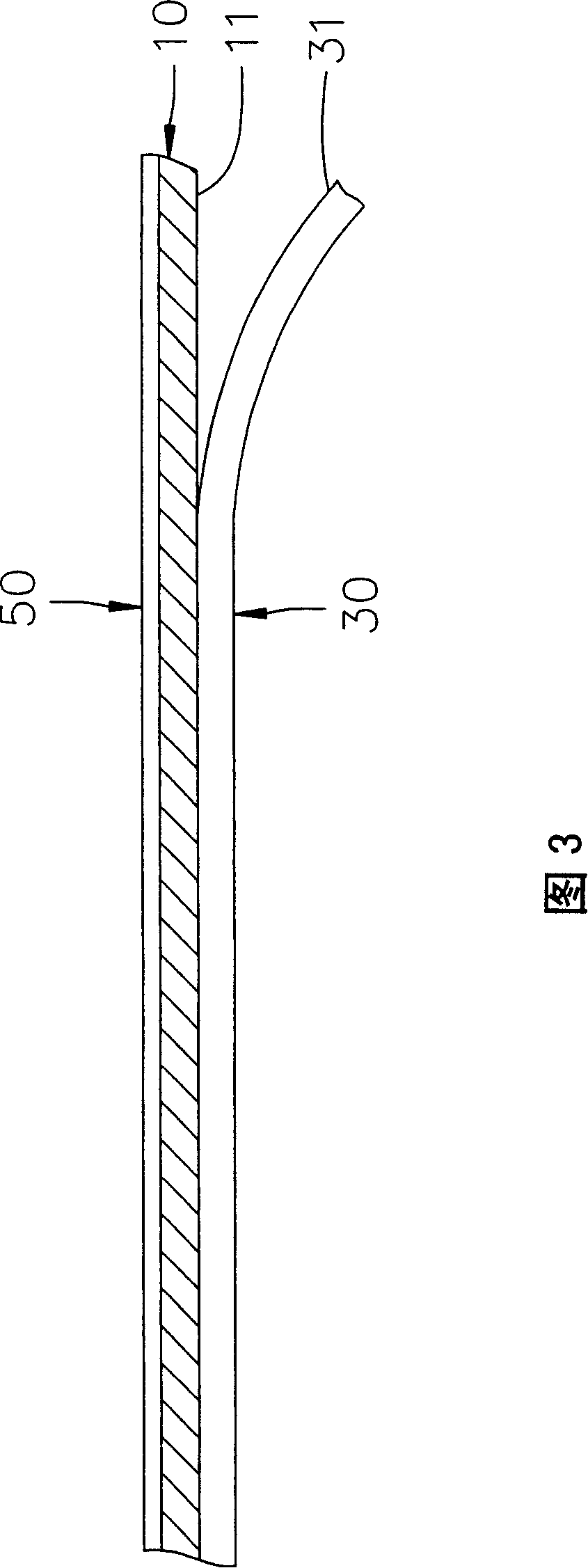

[0014] First, see figure 1 As shown in Figure 4, it is a preferred embodiment of the method for making a decorative cloth or decorative sheet with a three-dimensional pattern according to the present invention. The main manufacturing method includes the following steps:

[0015] (1) Mixed material:

[0016] The raw materials of the PU resin 10 are selected from the material group of isocyanate polymers, hydroxyl compounds and pigments of predetermined colors, and the required raw materials are placed in a material mixing device one by one. In the different material barrels 21 of 20, the material barrels 21 form the characteristics of the PU resin 10 according to the required characteristics, and the materials in each material barrel 21 flow to a vertical mixing tank 22 provided in the center of the material in proportion to mix, And make this raw material fully mix in this vertical mixing tank 22, then inject this PU resin 10 by a injection mixing head 23 below this vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com