Method and equipment for forming wood pattern by sand blasting

A technology of wood grain and sand blasting, which is applied in metal processing equipment, abrasive jet machine tools, abrasives, etc., and can solve the problems of inconspicuous annual ring lines, three-dimensional touch and relief effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

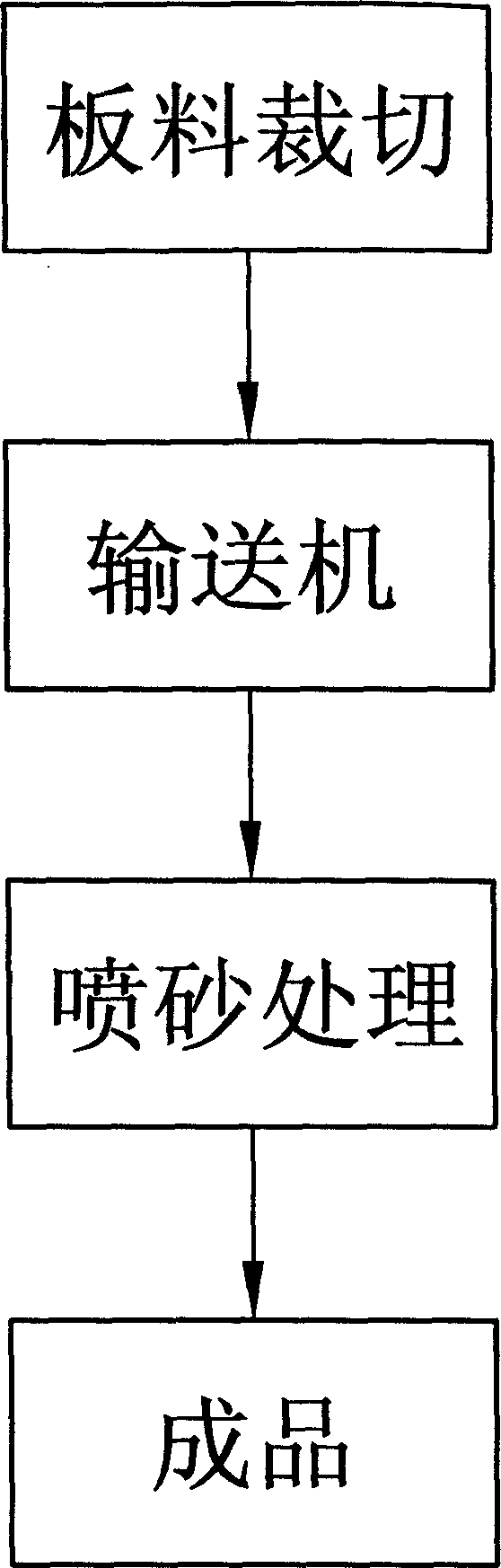

[0020] First, please refer to the Figure 2 to Figure 6 Shown, implementation steps and equipment of the present invention:

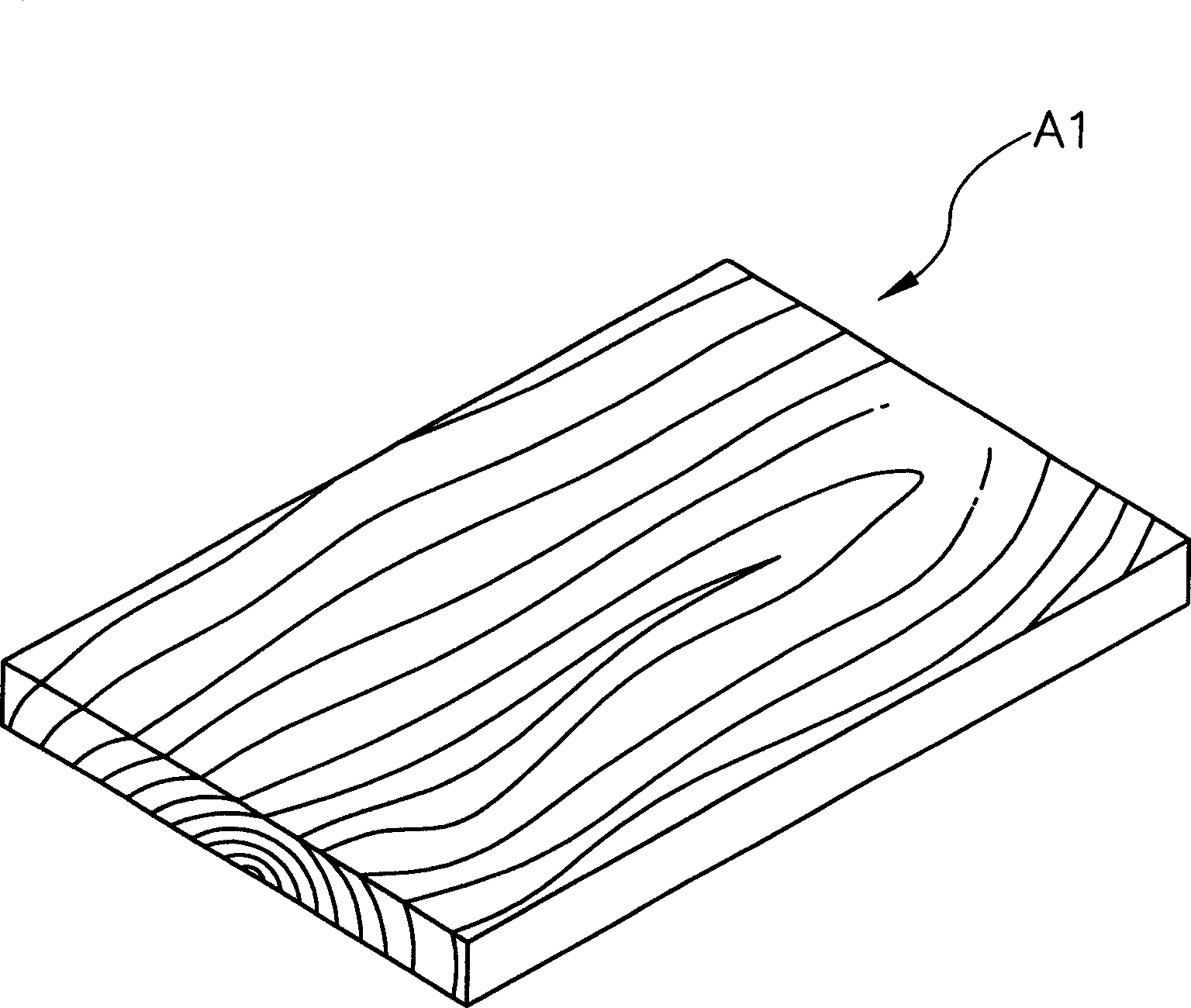

[0021] (1) Plate cutting: first take a plate 1 of a predetermined thickness from the crude wood product, and cut the plate 1 into a predetermined strip;

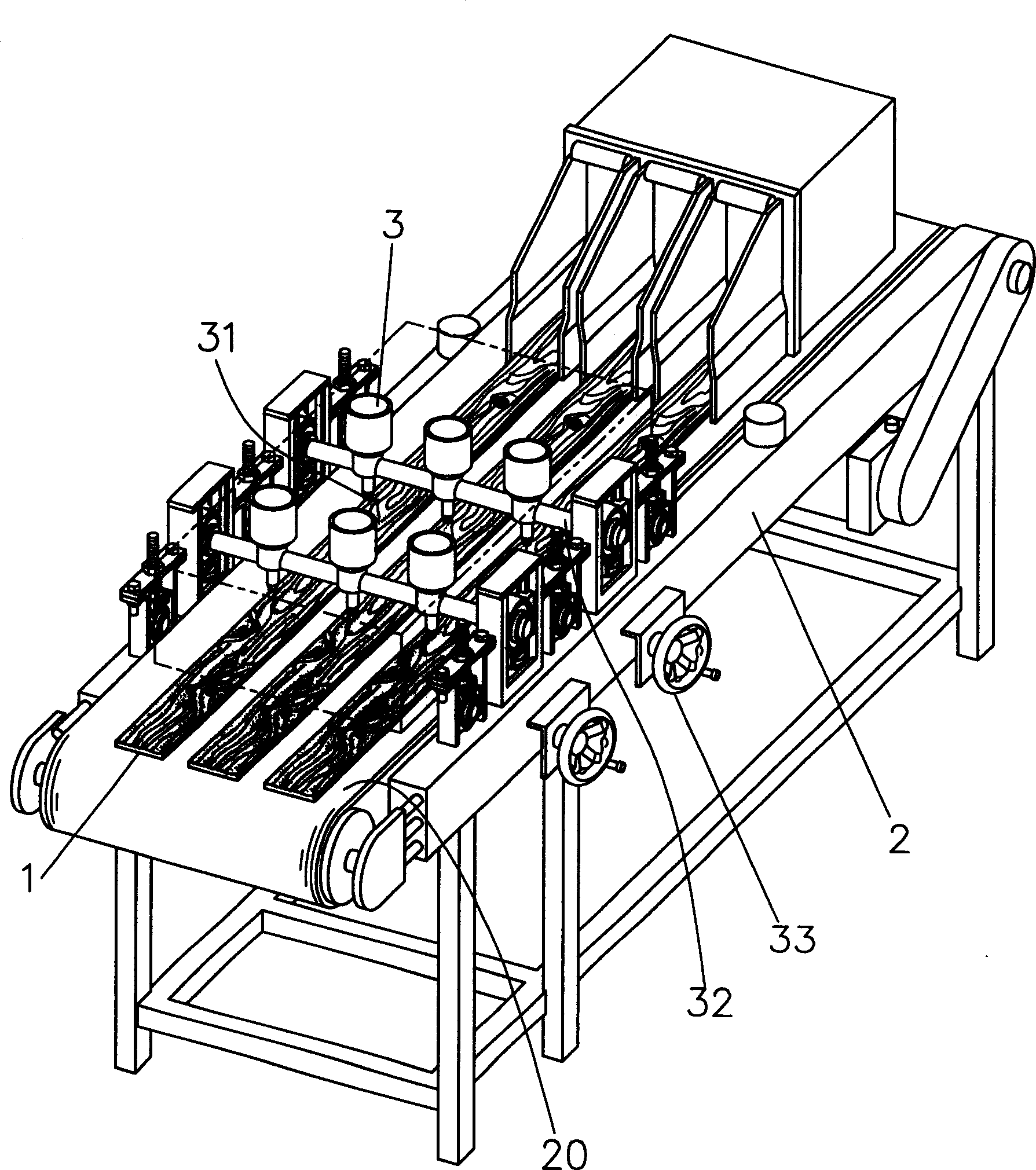

[0022] (2) The plates 1 are arranged on the conveyor 2, and a conveying platform 20 is set above the conveyor 2, and the plates 1 are automatically transported from the starting end to the end through the conveying platform 20;

[0023] (3) Sandblasting treatment: a number of sandblasting machines 3 are arranged on the upper side of the conveyor 2. Emery 30 is filled in the sandblasting machine 3, and a nozzle 31 is provided in front of the sandblasting machine 3, and the nozzle 31 is connected to the plate 1. Have proper distance, each sandblasting machine 3 is connected with connecting rod 32, and connecting rod 32 ends are provided with the adjuster 33 of turntable shape, for adjusting the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com