A kind of three-dimensional multi-color artificial leather car leather and preparation method thereof

A technology for imitating leather and automobile leather, applied in textiles and papermaking, etc., can solve the problems of physical performance index, poor touch, expensive raw materials, complicated preparation process, etc., to achieve excellent perforation performance, improved aesthetics, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

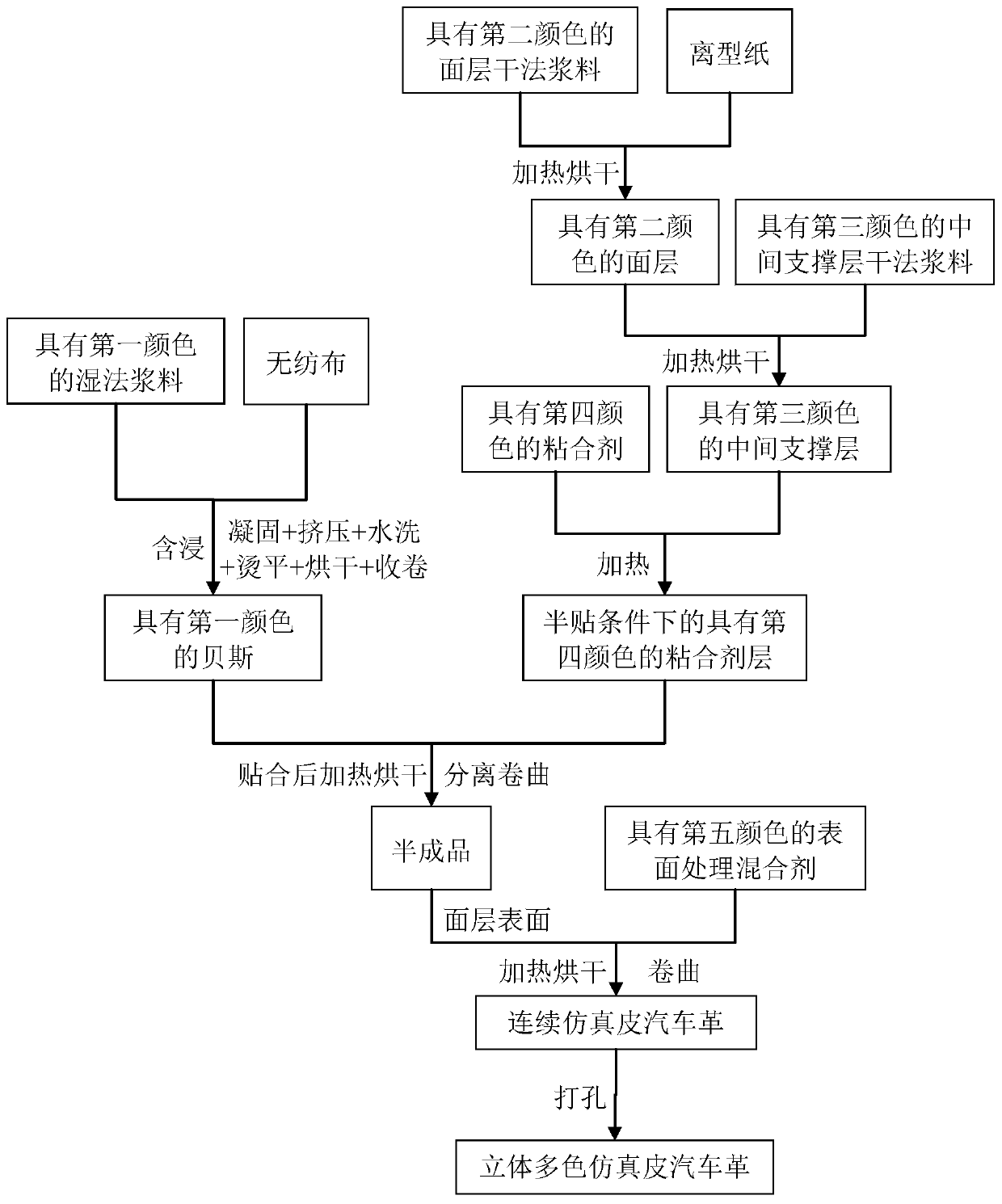

[0035] Such as figure 1 A kind of preparation method of three-dimensional multi-color imitation leather car leather of the present invention shown, comprises the following steps:

[0036] 1) Immerse the non-woven fabric in the wet slurry with the first color, impregnate the wet slurry on the non-woven fabric, and then wind it after coagulation-extrusion-washing-ironing-drying to obtain a Bass of the first color;

[0037] 2) Coating the surface layer dry-process slurry with the second color on the release paper, heating and drying to prepare the surface layer with the second color;

[0038] 3) Coating the intermediate support layer dry-process slurry with the third color on the dried surface layer, and heating and drying to prepare the intermediate support layer with the third color;

[0039] 4) Coating the adhesive with the fourth color on the dried intermediate support layer, and laminating it with the bass under the condition of semi-dry pasting, and making a semi-finished...

Embodiment 1

[0045] A preparation method of three-dimensional multi-color imitation leather car leather, comprising the following steps:

[0046]1) Prepare a bass with a first color. 100 parts by weight of wet-process resin, 600 parts by weight of DMF and 20 parts by weight of red slurry are evenly stirred to prepare red wet-process slurry, and the viscosity thereof is kept at 50±5cps. Put the above-mentioned red wet-process slurry in the impregnation tank, and immerse the non-woven fabric in the impregnation tank, impregnate the above-mentioned red wet-process slurry on the non-woven fabric at a speed of 20m / min with a gap of 0mm, and make the non-woven fabric at a speed of 20m / min. The non-woven fabric impregnated with red wet-process slurry passes through the coagulation tank, then squeezes the rollers with a gap of 0mm, washes with water at a speed of 20m / min, and then goes through 10 rounds of ironing at 150°C for each round and six rounds of ironing at 140°C for each round, and then ...

Embodiment 2

[0053] A preparation method of three-dimensional multi-color imitation leather car leather, comprising the following steps:

[0054] 1) Prepare a bass with a first color. 100 parts by weight of wet-process resin, 600 parts by weight of DMF and 20 parts by weight of red slurry are evenly stirred to prepare red wet-process slurry, and the viscosity thereof is kept at 50±5cps. Put the above-mentioned red wet-process slurry in the impregnation tank, and immerse the non-woven fabric in the impregnation tank, impregnate the above-mentioned red wet-process slurry on the non-woven fabric at a speed of 20m / min with a gap of 0mm, and make the non-woven fabric at a speed of 20m / min. The non-woven fabric impregnated with red wet-process slurry passes through the coagulation tank, then squeezes the rollers with a gap of 0mm, washes with water at a speed of 20m / min, and then goes through 10 rounds of ironing at 150°C for each round and six rounds of ironing at 140°C for each round, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com