Manufacturing method of plane baked vein board

A patterned plate and plane technology, which is applied in the field of planar baked plate production, can solve the problems of adhesive degradation, difficult polishing, and uneven surface of three-dimensional lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is for reaching above-mentioned object and effect, and the technical means that adopts, presents preferred feasible embodiment hereby, and cooperates as shown in the accompanying drawings, is described in detail as follows:

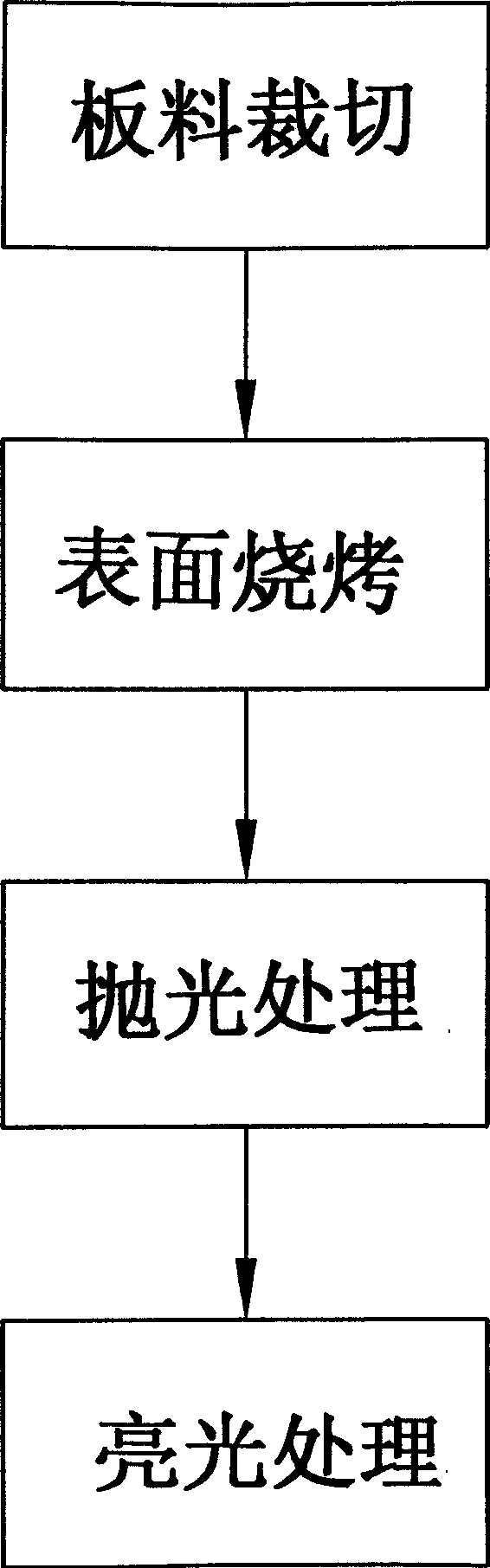

[0020] First, please refer to the Figure 1 ~ Figure 3 Shown, the implementation steps of the present invention are:

[0021] (1) Sheet material cutting: first process the rough wood product into a sheet material 1 of predetermined thickness, and then cut the sheet material 1 into a predetermined shape;

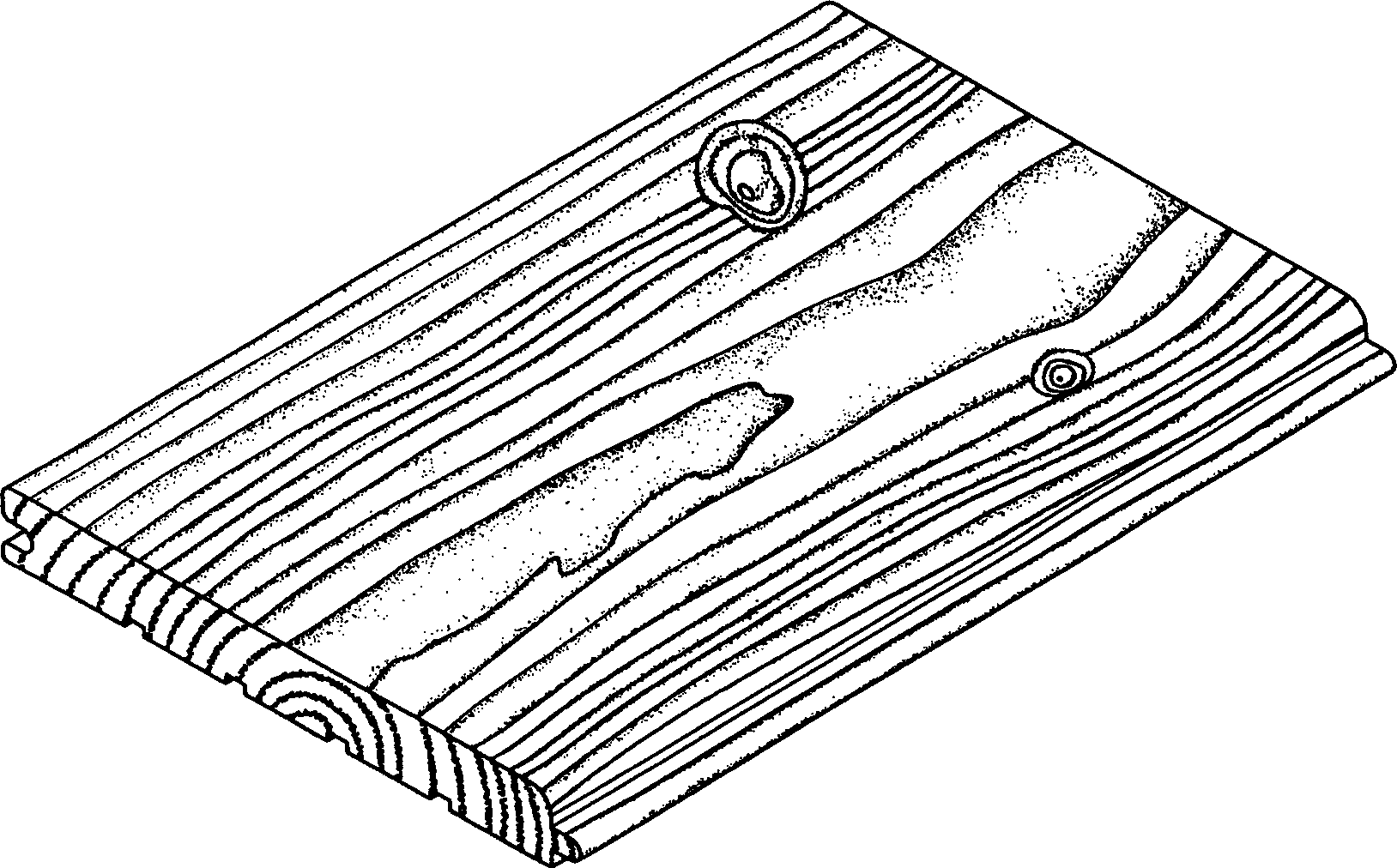

[0022] (2) Surface grilling treatment: quickly grill the surface of the cut sheet 1 at high temperature, so that the surface of the sheet 1 presents a color difference of depth and depth according to the texture of the wood;

[0023] (3) Polishing treatment: for the sheet 1 after step (2), use a sandpaper wheel to remove the scorched part of the surface due to carbonization during the barbecue treatment, to level the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com