Cereal/stone fruit chocolate preparation method

A chocolate and stone fruit technology, applied in the field of food, can solve the problems of single edible form of chocolate and few chocolates, etc., and achieve the effects of good visual effect of appearance, improved edible grade and good visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Take fresh japonica rice, wash it with water, cook it half-cooked, drain the water, air drench to remove the surface water, crush it into rice flour, mix with a little salt, pepper, sugar powder, monosodium glutamate, and salad oil, and add it to an appropriate ball Bake in an oven until fine cracks appear on the surface and the white color remains unchanged. They are cooked rice noodle balls. Place them on a stainless steel plate and remove the remaining water directly at 15°C until the water content reaches 3%.

[0015] 2) After melting the chocolate block at 45°C, pour it into a PE plastic sheet model with a thickness of 0.01mm, and mold the chocolate after cooling;

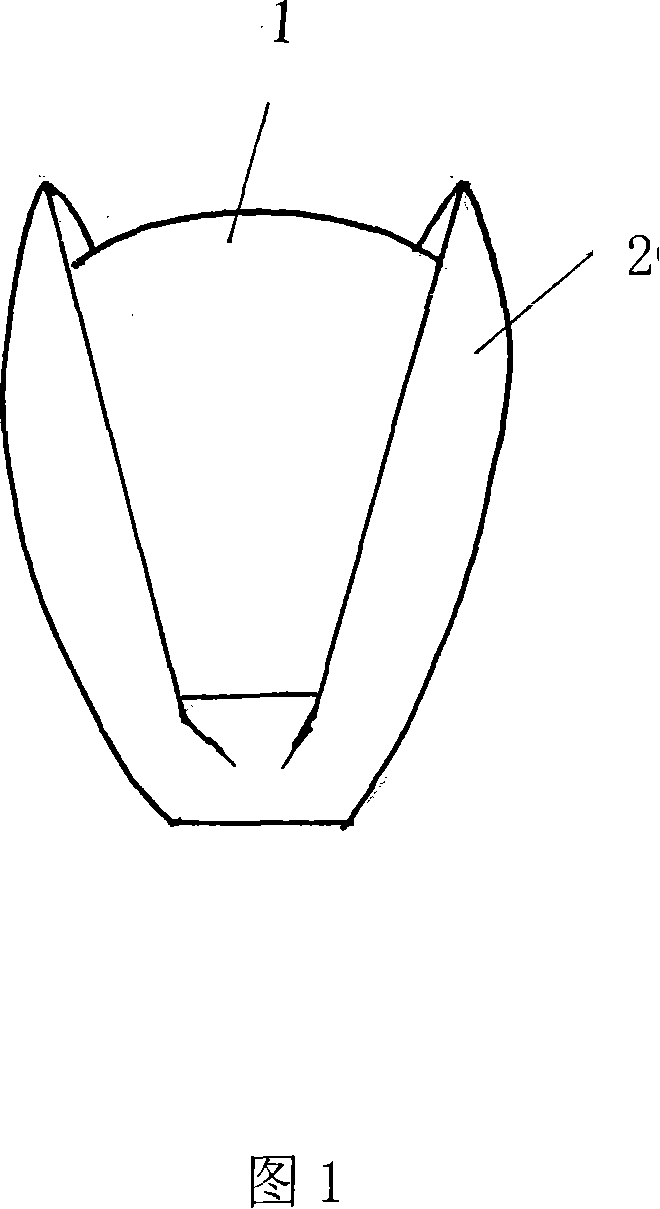

[0016] 3) Dip the chocolate syrup on the bottom of the dehydrated rice flour ball, and then take two pieces of shaped chocolate to inlay on both sides, the lower part is combined with the chocolate syrup at the bottom of the dehydrated rice flour ball, and the upper part is opened at a certain angle t...

Embodiment 2

[0019] 1) Take fresh chestnuts, rinse them with water for 20-30 minutes, use a knife to cut the skin in a "cross" shape on the raised part, put it in a cage and steam for 30-40 minutes, take it out and shower with air until the skin cracks, and peel off the chestnut kernels , placed in a stainless steel plate, quickly frozen in a vacuum drying chamber at -40°C until the central temperature is lower than -18°C, then heated to -28°C and vacuumed to remove moisture to a water content of 30%, and then slowly heated to -15°C Dehydration for 10 hours, dehydration for 5 hours at 15°C until the water content is 3%;

[0020] 2) After melting the chocolate block at 45°C, pour it into a PE plastic sheet model with a thickness of 0.01mm, and mold the chocolate after cooling;

[0021] 3) Dip the chocolate slurry on the bottom of the ripened dehydrated chestnut, and then take two pieces of shaped chocolate to inlay on both sides, the lower part is combined with the chocolate slurry at the b...

Embodiment 3

[0024] 1) Wash ginkgo fruit, steam for 15-20 minutes, take nuts, and remove surface moisture. Put it on a stainless steel plate, freeze it quickly at -40°C in the vacuum drying chamber until the center temperature is lower than -18°C, then heat it up to -28°C and vacuumize it to dehydrate it to a water content of 20%, and continue to slowly heat up to -15°C for dehydration 10 hours, dehydration at 15°C for 5 hours to a moisture content of 2%;

[0025] 2) Take the white sugar-free chocolate block and melt it at 45°C, pour it into a PE plastic sheet model with a thickness of 0.01mm, and mold it into chocolate after cooling;

[0026] 3) Dip the chocolate slurry on the bottom of the ripened dehydrated ginkgo fruit, and then take two pieces of ginkgo shell shaped chocolate to inlay on both sides, the lower part is combined with the chocolate slurry at the bottom of the ripened dehydrated ginkgo fruit, and the upper part is opened at a certain angle to expose the ripened dehydrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com