Backlight module and light guiding board

A technology of backlight module and light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problem of low brightness in the center of the light guide plate, and achieve the effect of good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

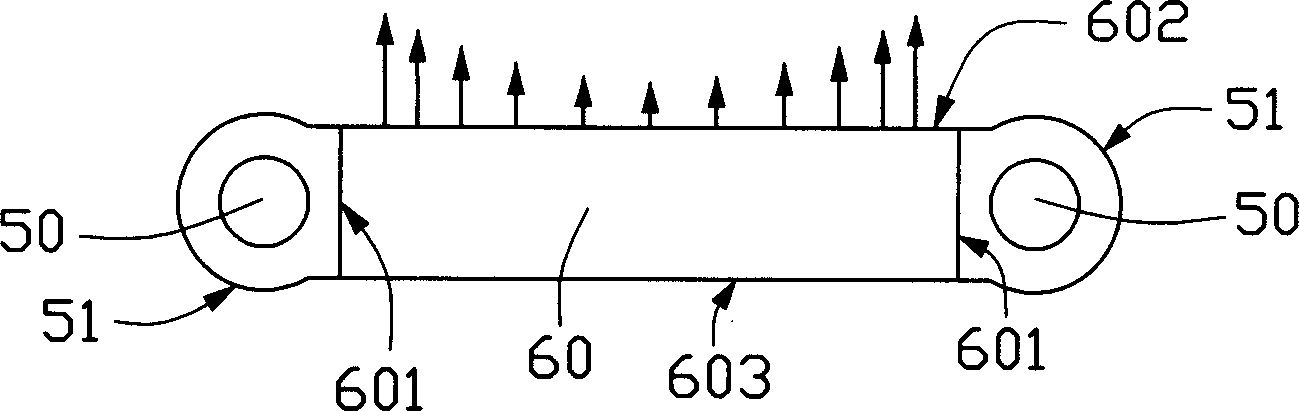

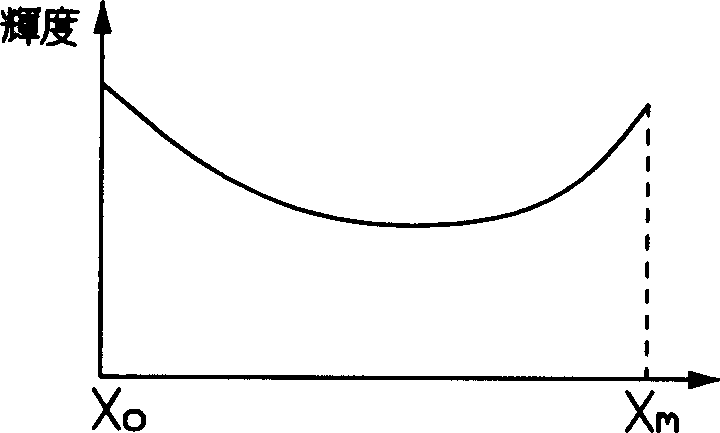

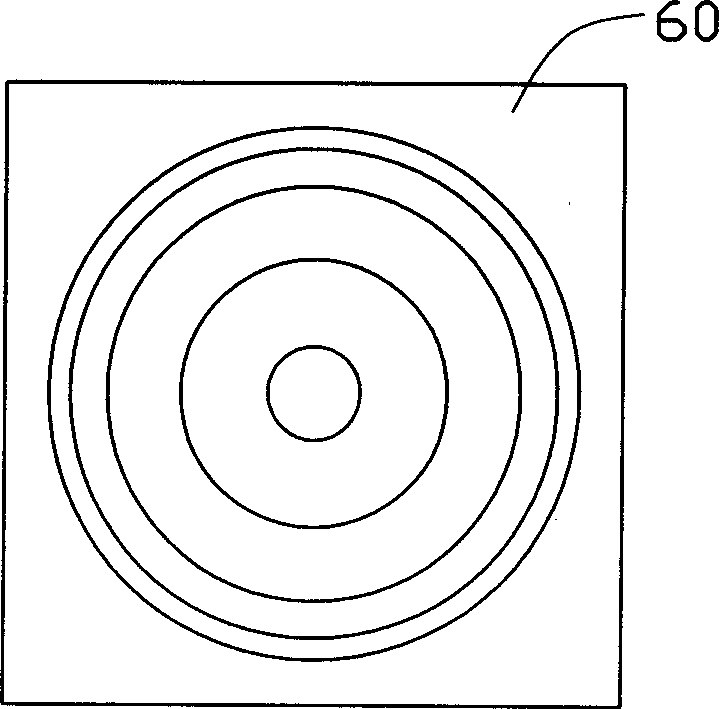

[0019] see Figure 4 and Figure 5 , is a structural schematic diagram of the backlight module of the present invention and a schematic diagram of the luminance distribution of the light guide plate. The backlight module includes a set of line light sources 10, a set of reflectors 11 arranged around the line light source 10, a light guide plate 20 and a light enhancement sheet 25, and the light guide plate 20 includes a light incident surface 201, a light exit surface 203 and a bottom surface 202 , the line light sources 10 are respectively located on the sides of the light incident surface 201 of the light guide plate 20 . The light emitted by the line light source 10 is transmitted in the light guide plate 20 , reflected multiple times between the light incident surface 201 and the bottom surface 202 , and finally exits from the light exit surface 203 and enters the brightness enhancement sheet 25 . The line light source 10 can be a CCFL (Cold Cathode Fluorescent Lamp, col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com