Hand-tear texture anti-counterfeit method and product and material thereof

A texture and hand-tearing technology, which is applied to the recording carriers used by machines, instruments, computer parts, etc., can solve the problem of polluting ordinary white paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

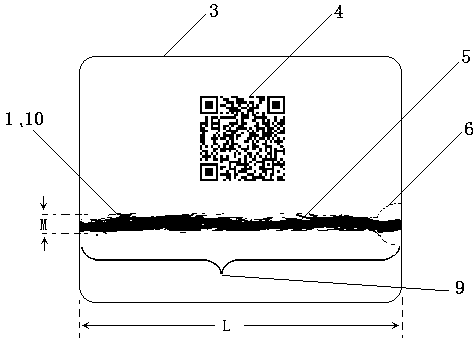

[0130] Such as Figure 11 As shown, referring to the composite production process of the utility model patent "laser holographic safety thread composite packaging box (CN2399334Y)", the surface layer of the transparent BOPP film is composited with the bottom layer of white PE, and at the same time, a strand of 7 x 0.5D black polyester Napped yarn—fancy yarn, pulled out from the unwinder and buried between its two layers, crushed and deformed (flattened) by a super calender and ensured that all the hairs on it are stuck, clamped, Stationary to create a substrate for fancy yarns with napped yarns inside.

[0131] Such as figure 1 As shown, the above-mentioned brushed yarn-type printing material is used to print printed matter, and a unique sequence code containing a link address—code—is printed on each printed matter with an inkjet printer.

[0132] Prepare an industrial-grade digital camera. After the flat texture string releases the stress and is completely shaped, each cod...

Embodiment 2

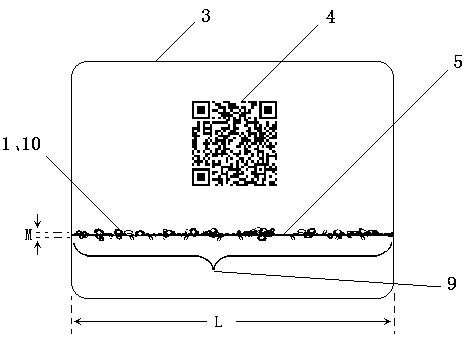

[0139] Such as Figure 12 As shown, the 1st and 2nd are loop yarns, and the 3rd is textured yarn, both of which are fancy yarns, pull them out from the pay-off device, place them at a certain distance, and bury them between the two layers of pulp. During this time, it is rolled and deformed (flattened) by a super calender to produce fancy yarn-like printing materials embedded with loop yarn and textured yarn. This printing material can be used to print such as figure 2 Prints shown. Other steps can be the same as in the embodiment.

Embodiment 3

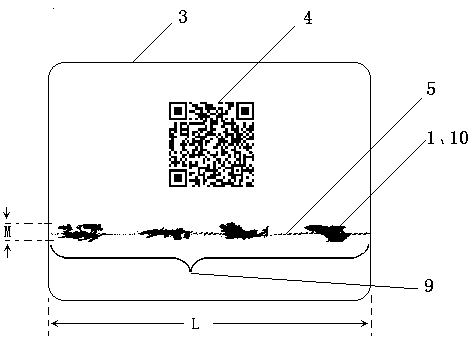

[0141] Such as Figure 13 As shown, bundles of colorful wrapped toothbrush yarns—fancy yarns—are pulled out from the unwinder, spaced at a certain distance, buried between two layers of pulp, and rolled and deformed by a super calender (Squeeze), the thickness of the flat texture string after flattening is preferably 25-35μm, so as to produce a printing material embedded with fancy yarn wrapped with toothbrush yarn. This printing material can be used to print such as image 3 Prints shown. Other steps can be the same as in the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com