Disposable uncovered holographic electronic tag antenna and its manufacturing method and application

A technology of electronic tags and manufacturing methods, applied to antennas, antenna parts, antenna supports/installation devices, etc., to achieve the effects of increasing aesthetics, reducing costs, and simplifying manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1, a disposable holographic electronic tag antenna made of fragile paper and applied to RFID:

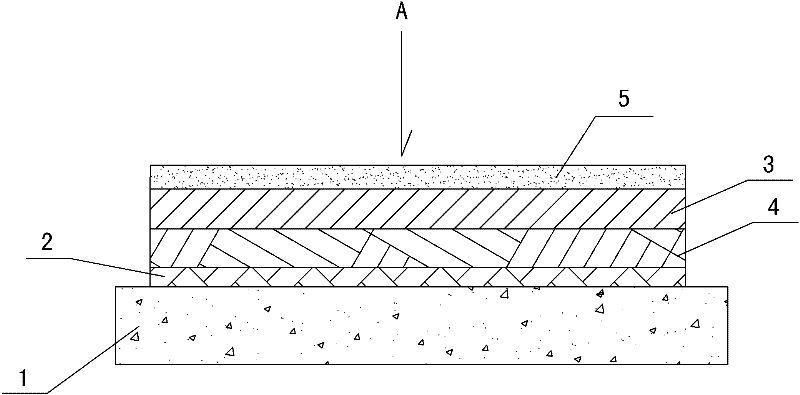

[0046] (1) Choose fragile paper as the substrate layer (thickness 0.5mm ~ 2.5mm), and coat one side of the substrate layer to ensure the smoothness of the processed surface suitable for the antenna to form the antenna processed surface.

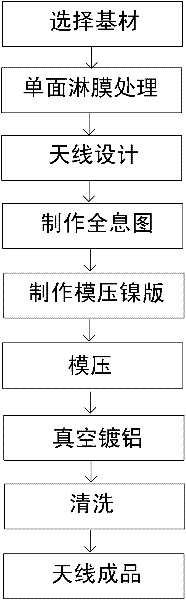

[0047] (2) Preparation of antenna holographic layer:

[0048] a. Antenna design: UHF2.45GHZ antennas are made according to customer requirements. The reading distance is 10-15m; The impact of the actual half-wave dipole antenna is required to be 57mm in length, the antenna input impedance is about 72Ω, the impedance bandwidth is 14.3% when the voltage standing wave ratio (VSWR) is less than 2.0, and the antenna gain is 1.8.

[0049] b. Make a hologram: According to the designed antenna size and shape, take an information map of the antenna. This information map is the master plate for making a hologram. It is composed of dense, intr...

Embodiment 2

[0060] Example 2: Disposable uncovered holographic electronic tag antenna for RFID made of polyester film:

[0061] (1) Select polyester film as the substrate layer (thickness 0.6-1.6mm), and perform coating treatment on one side of the substrate layer to ensure the smoothness of the processing surface suitable for the antenna to form the antenna processing surface.

[0062] The steps of (2) preparing the antenna hologram layer, (3) vacuum aluminum plating and (4) cleaning are the same as in Example 1.

[0063] (5) Product inspection:

[0064] Test results: When the chip used in the antenna is at 915MHZ, the external impedance is Z=18.1-j149Ω. In order to realize the maximum power transmission between the tag chip and the tag antenna, the antenna impedance should be 18.1+j149Ω at the resonant frequency. When the standing wave ratio is less than 2, the bandwidth is 218MHz (802MHz ~ 1.02GHz), which meets the design requirements of UHF frequency band, and the relative bandwidth ...

Embodiment 3

[0065] Example 3: Disposable uncovered holographic electronic tag antenna for RFID made of coated paper:

[0066] (1) Select coated paper as the substrate layer (thickness 1.6mm), and coat one side of the substrate layer to ensure the smoothness of the processed surface suitable for the antenna to form the processed surface of the antenna.

[0067] The steps of (2) preparing the antenna hologram layer, (3) vacuum aluminum plating and (4) cleaning are the same as in Example 1.

[0068] (5) Product inspection:

[0069] Test results: When the chip used in the antenna is at 2.45GHZ, the input impedance of the antenna is 75Ω, the impedance bandwidth is 14.3% when the voltage standing wave ratio is less than 2, and the antenna gain is 1.8. For most RFID application systems, the antenna can meet Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com