Invisible Window Intelligent Production Line

A production line and intelligent technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, complex procedures, and time-consuming, reducing labor intensity, high degree of automation, and avoiding manual operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

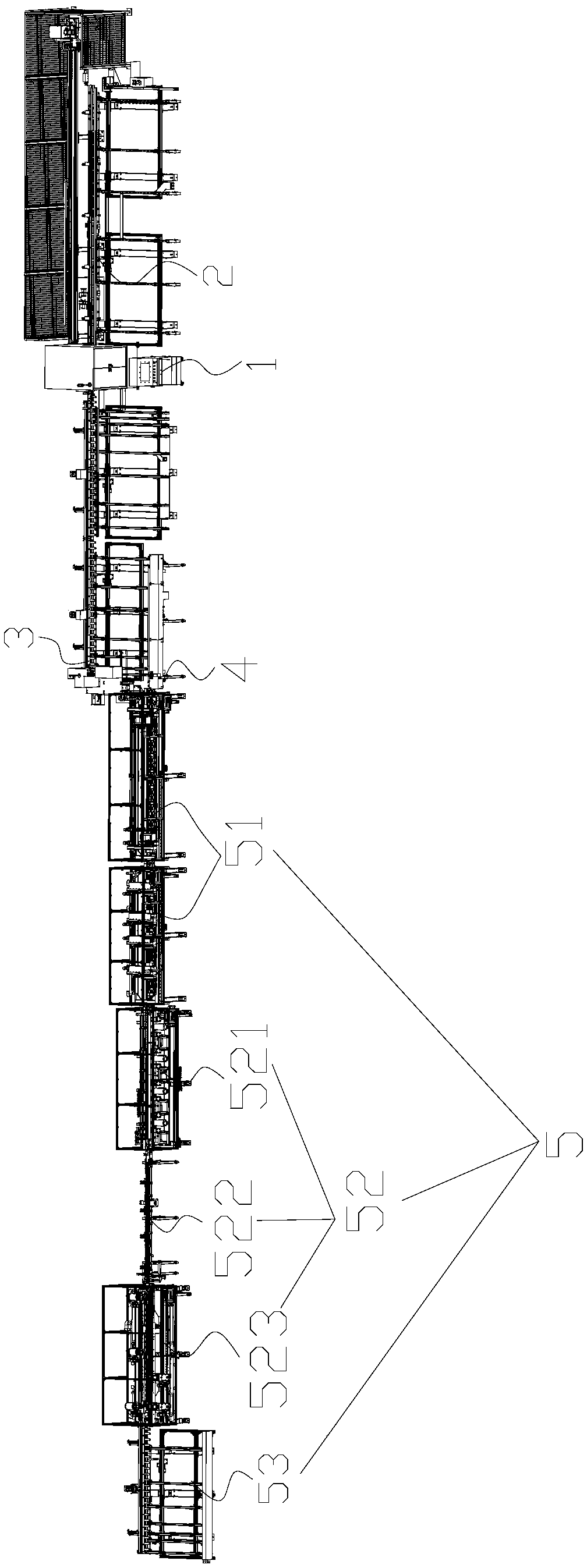

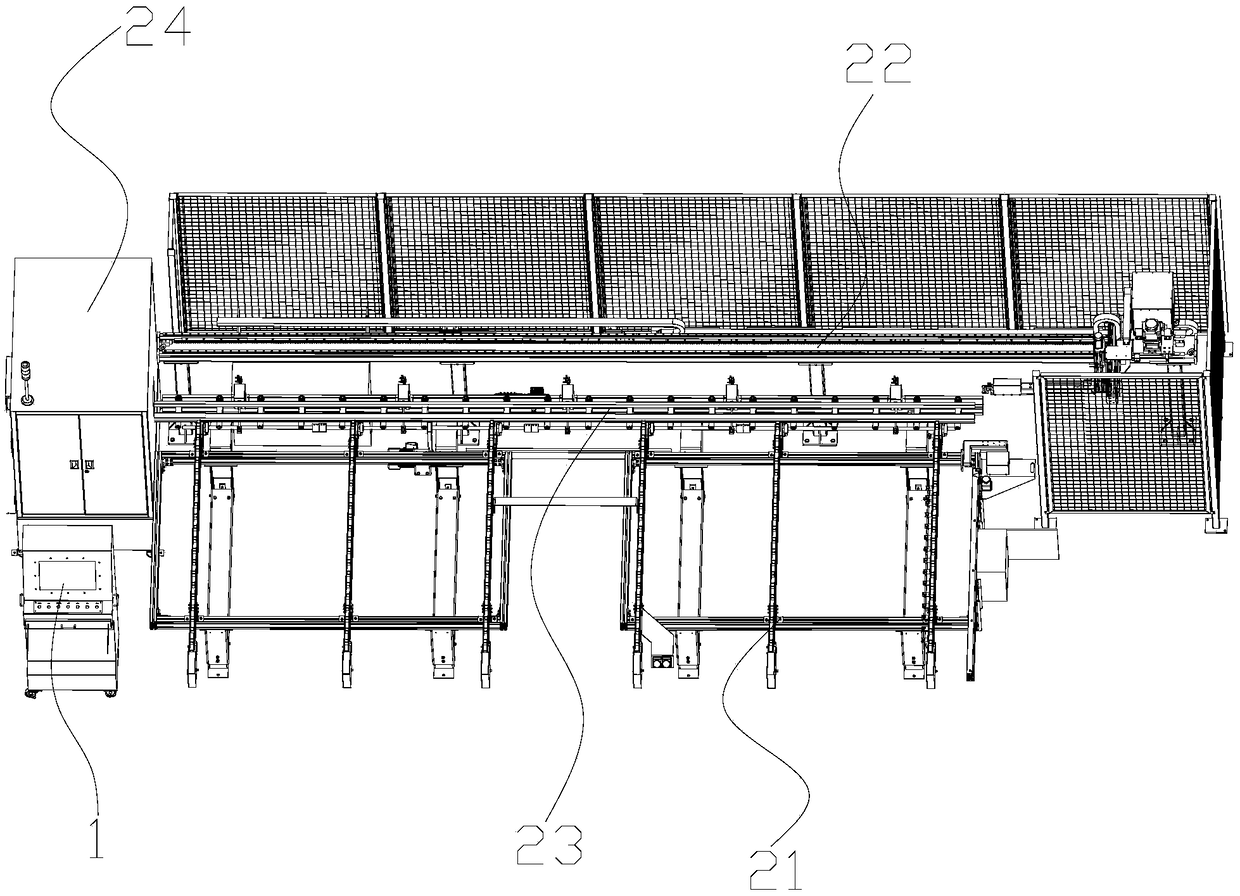

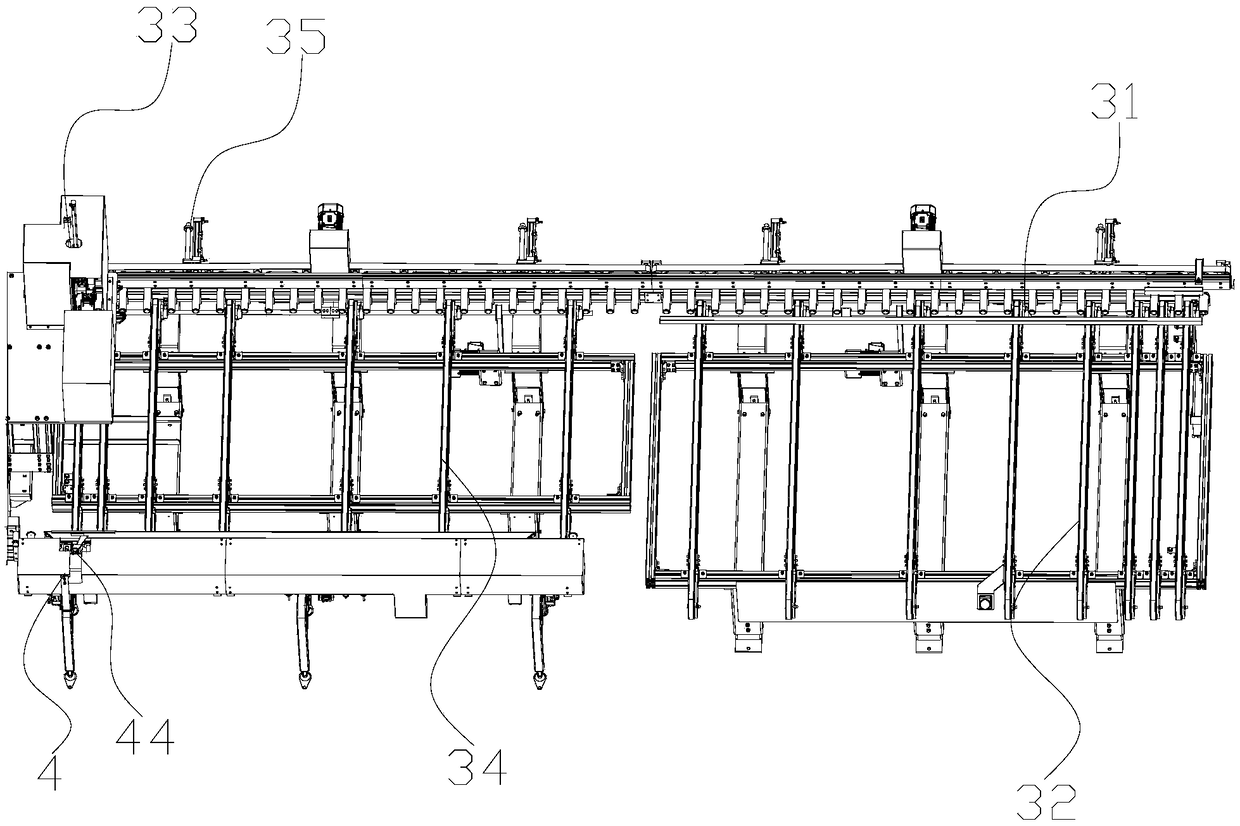

[0063] See Figure 1 to Figure 9, an invisible window intelligent production line, comprising: a parameter generation device 1, a raw material cutting device 2, a product labeling device 3, a label identification device 4 and a processing device 5. Among them, the parameter generation device 1 generates a corresponding bill of materials and raw material cutting parameters and label parameters corresponding to the bill of materials according to the order; the raw material cutting equipment 2 is connected to the parameter generation device 1 and according to the raw material of the parameter generation device 1 cutting parameters to cut the raw material; the product labeling device 3 is connected to the parameter generating device 1 and according to the label parameters of the parameter generating device 1, the raw material cut by the raw material cutting equipment 2 is labeled with a corresponding label; the label identification device 4 scans The label generates a correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com