Automatic assembly line equipment for steam finish-ironing and shaping

An automatic assembly line and steam technology, which is applied to wrinkle-removing and flattening equipment, finishing appliances, laundry room devices, etc., can solve the problems of changing shapes, hats and socks cannot be flattened, and cannot be shaped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

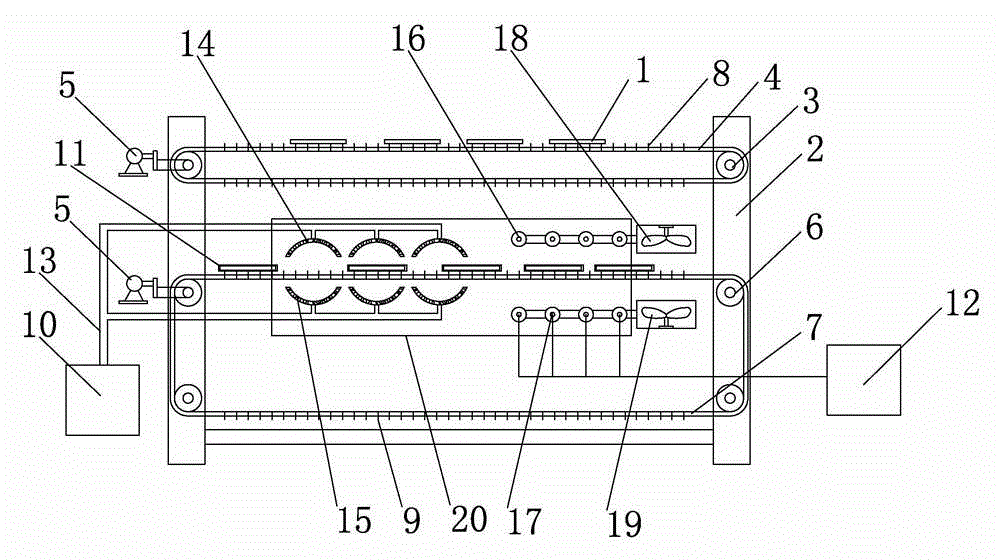

[0011] The present invention will be further described below in conjunction with accompanying drawing:

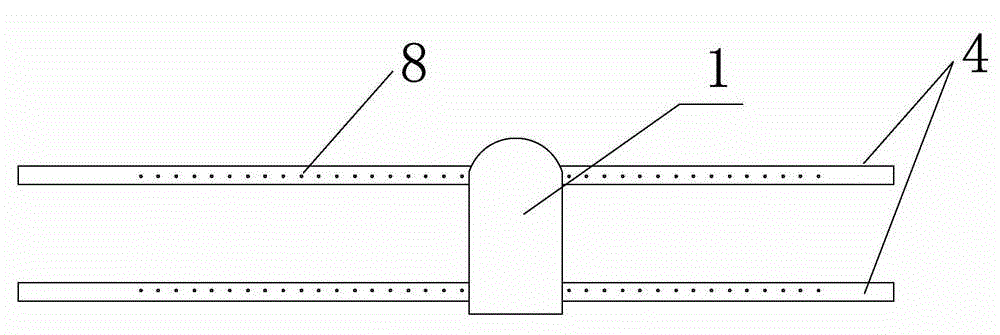

[0012] like Figure 1-2 As shown, this steam ironing and shaping automatic assembly line equipment mainly includes a frame 2, and the frame 2 is provided with an upper transmission line composed of an upper chain wheel 3 and an upper chain 4, and the upper chain 4 is fixedly connected with a A set of upper support pins 8 is used to place the template 1; the frame 2 is provided with a lower transmission line consisting of a lower sprocket 6 and a lower chain 7, and a set of lower support pins 9 are fixedly connected to the lower chain 7 for placing Put on the template 11 of the cap socks; the lower floor chain 7 passes through the closed steam drying box 20, and the steam drying box 20 is provided with a steam treatment section formed by the upper steam nozzle 14 and the lower steam nozzle 15, and the upper steam injection The pipe 14 and the lower steam spray pipe 15 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com