Shoe side part and heel part integrated lasting machine

A clamping machine and integrated technology, applied in the direction of shoe-making machinery, footwear, and adhesive shoe parts, etc., can solve the problems of insufficient action, unsatisfactory structure, and poor quality of the knot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

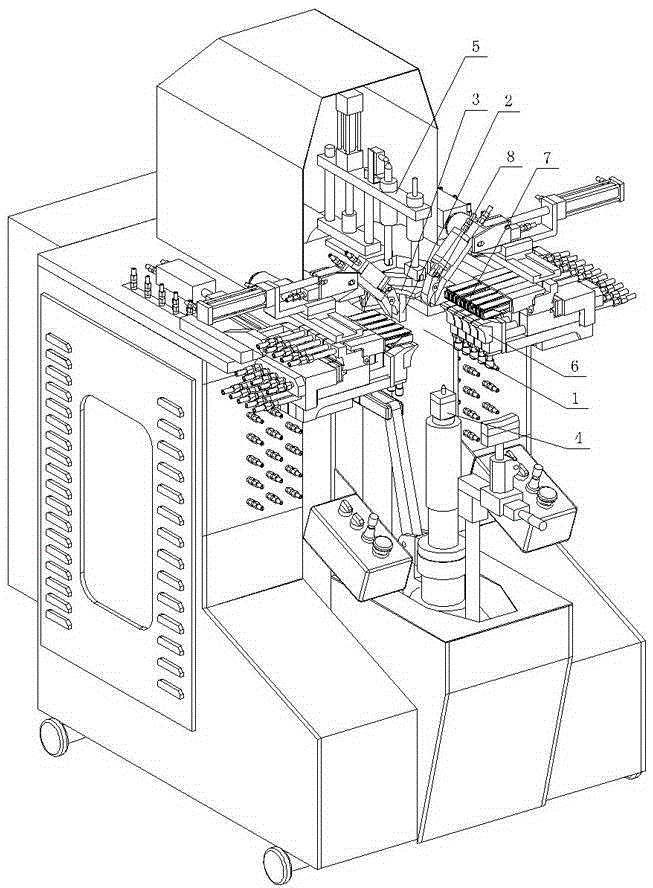

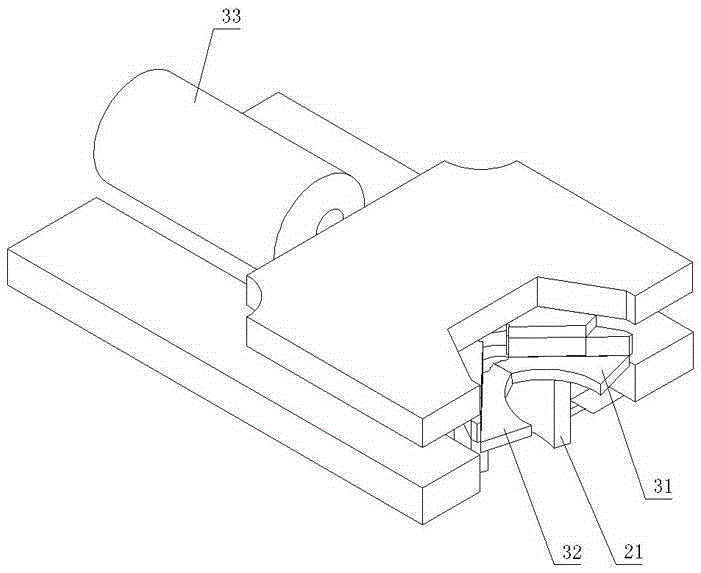

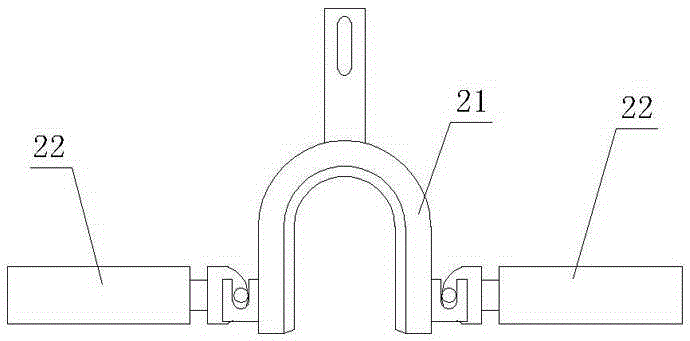

[0023] Such as figure 1 As shown, the shoe mid-back integrated upper clamping machine of the present invention includes a clamping station 1. When the clamping work is performed, the shoe last embedded in the upper surface is placed upside down with the last facing outward, and the shoe last is put into the space in front of the clamping station 1. A shoe last heel holding part 2 is provided behind the clamping station 1, a rear sweeping knife part 3 is provided above the shoe last heel holding part 2, a shoe last lifting part 4 is provided under the clamping station 1, and a shoe last lifting part 1 is provided under the clamping station 1 A shoe last pressing part 5 is arranged on the top, a shoe last side holding part 6 is arranged on the left and right sides of the clamping station 1, a side sweeping knife part 7 is arranged above the shoe last side holding part 6, and a side sweeping knife part 7 is arranged above the side sweeping knife part 7. There are middle side clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com