Method for drilling rolled flexible printed circuit board

A flexible circuit board, roll-shaped technology, applied in the direction of electrical connection formation of printed components, etc., can solve the problems of polluting products, machines or work areas, increasing costs, and copper foil material products are prone to wrinkles, etc., to save laser processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

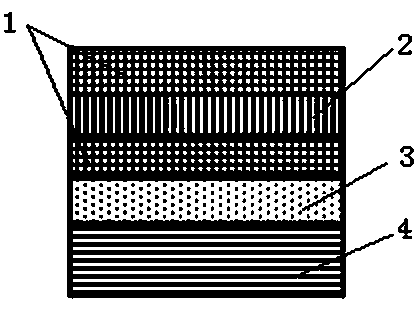

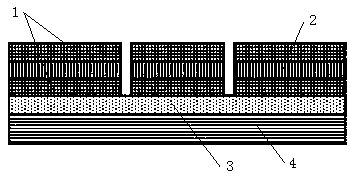

[0023] A method for rolling holes in a flexible circuit board 1, comprising the following steps: (1) attaching a layer of carrier film 4 to one side of a roll-shaped raw material; The raw materials are used to make holes; (3) The above-mentioned carrier film 4 is torn off to make a flexible circuit board 1 with holes.

[0024] An adhesive layer 3 is provided between the roll-shaped raw material and the carrier film 4. In order to prevent the copper foil from wrinkling during processing, and the carrier film 4 is easy to tear off, the thickness of the adhesive layer 3 is preferably 0.5-50um; The junction layer 3 is composed of weakly cohesive polypropylene adhesive or epoxy adhesive.

[0025] The raw materials are composed of: single-layer flexible circuit board 1; the raw materials can also be composed of: multi-layer flexible circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com