Mulch applicator special for tobacco field

A technology of laminating machine and tobacco field, which is applied in the direction of plant protection cover, etc., can solve the problems of lax sealing of soil, mechanical cutting of film, loose film of laminating machine, etc., so as to ensure smoothness, reasonable design and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

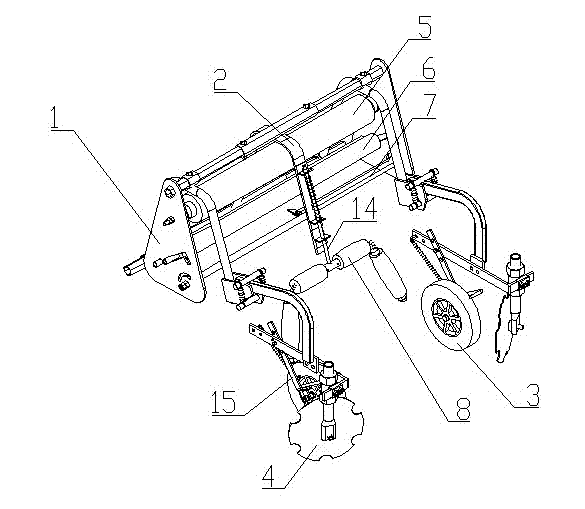

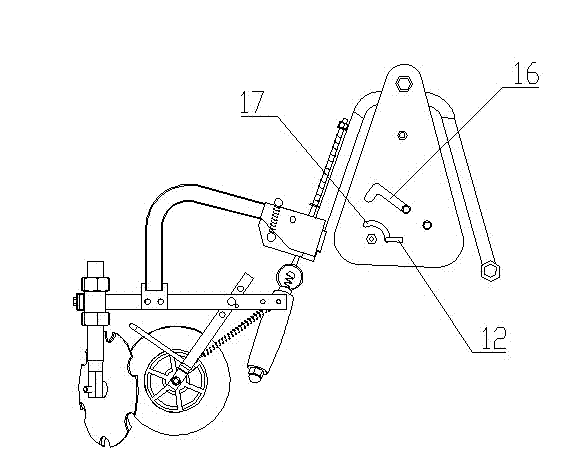

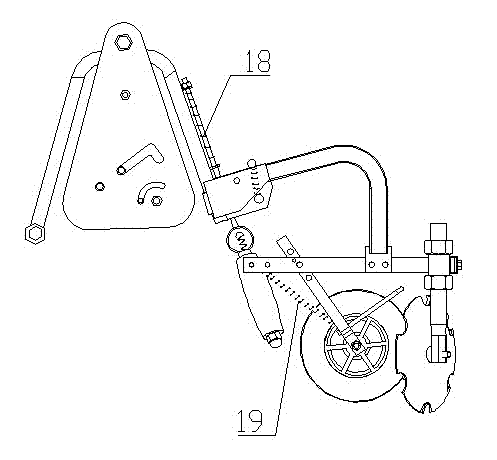

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. As shown in the figure: the special laminating machine for tobacco fields includes a frame 2, a film pressing wheel 3, a soil knife 4 and two supporting film frame side plates 1; On the side, a film roller 5 is arranged between the two supporting film frame side plates 1, and two earthen knives 4 are respectively arranged on both sides of the frame 2 behind the film roller 5, and a film cutting knife is arranged obliquely below the film roller 5 Device 7, film cutting knife device 7 comprises cutting knife 10, slide knife shaft 11, pull bar 12 and carrying knife shaft sleeve 13, and cutting knife 10 is located on the slide knife shaft 11 by carrying knife shaft sleeve 13, and slide knife shaft 11 two The two ends are respectively fixed on the side plates 1 of the two supporting membrane frames, the pulling rod 12 is parallel to the slider shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com