Oven with steam cleaning function and steam cleaning method thereof

A steam and functional technology, applied in the field of steam oven and its steam cleaning, can solve the problems of unfavorable uniform heating of food, uneven steam, impossibility of steam cleaning, etc., and achieve simple and reasonable structure design, uniform steam injection, free and smooth rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

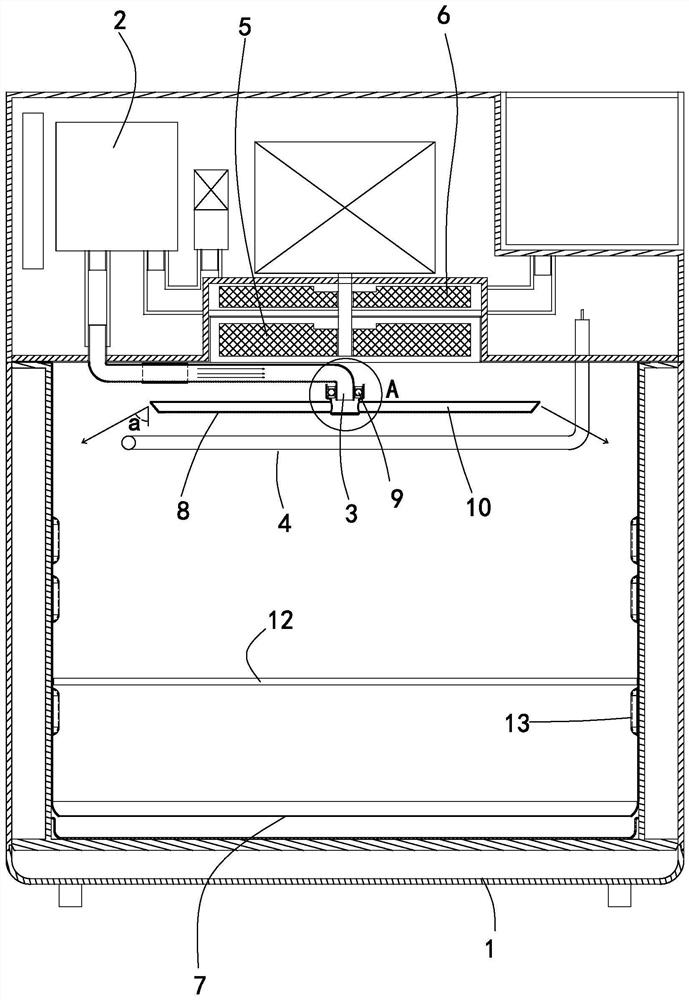

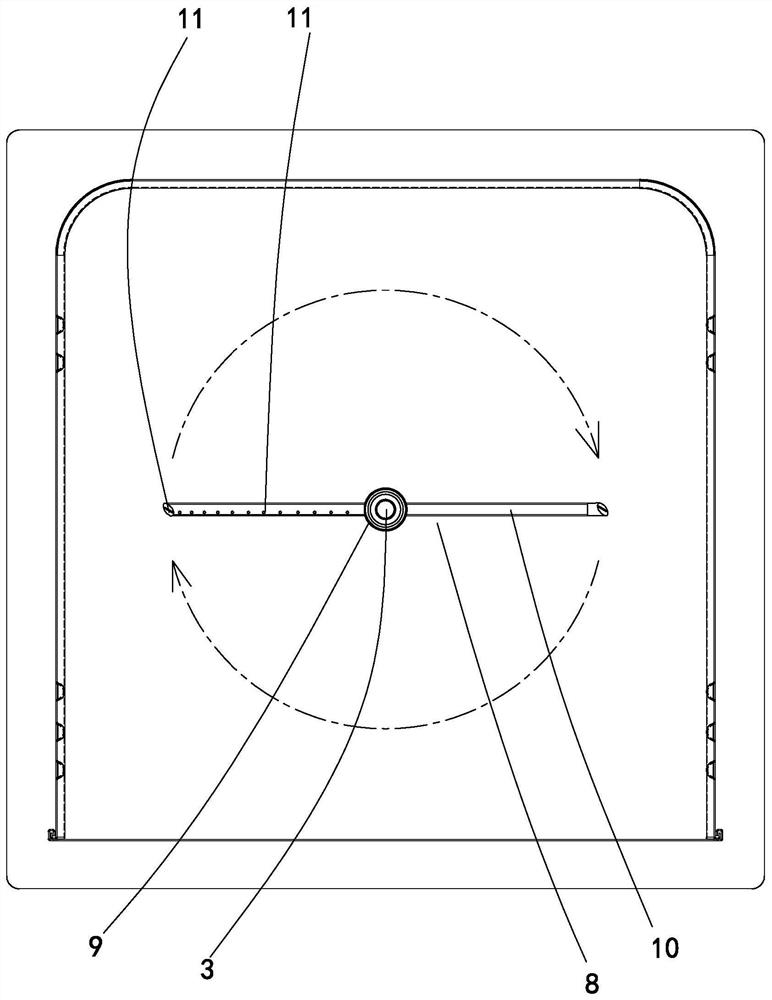

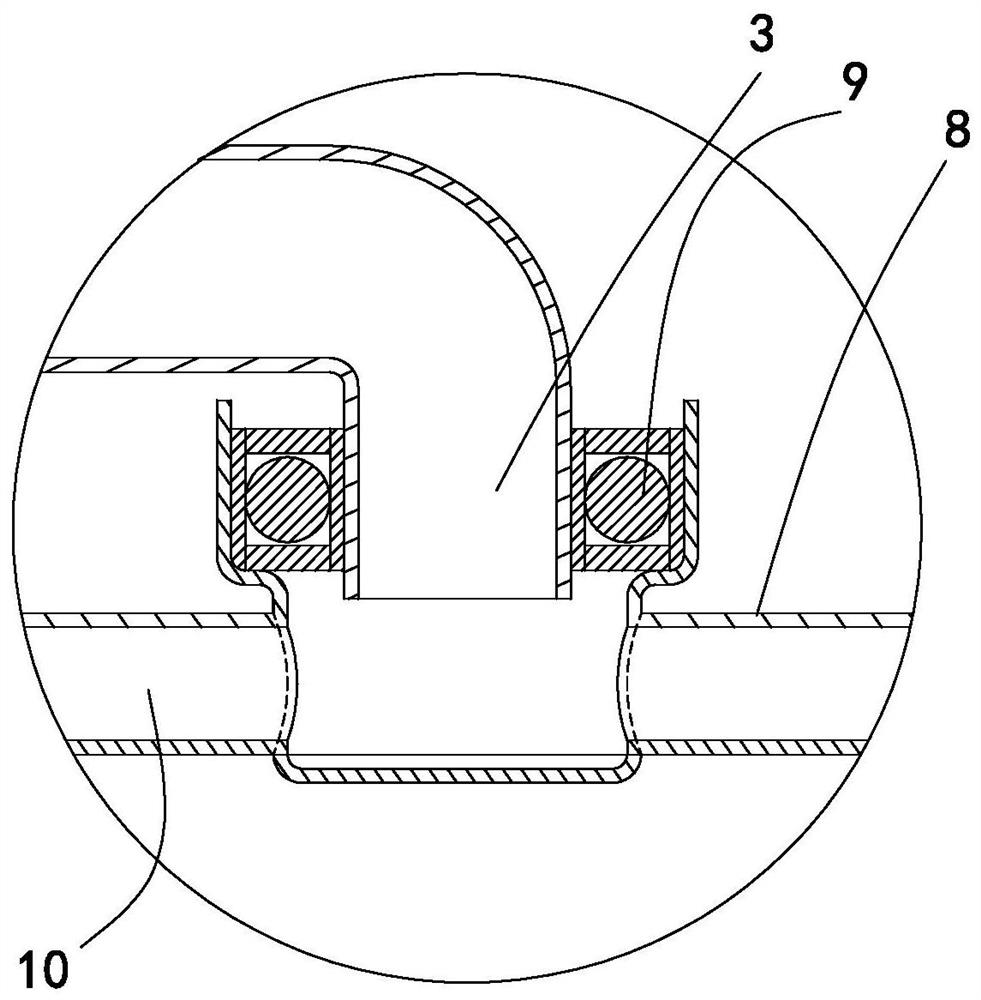

[0020] Embodiments, with reference to the accompanying drawings, an oven with steam cleaning function, including a box body 1 and a box door, the top of the box body 1 is provided with a steam generating device 2, a steam nozzle 3, a heating pipe 4, a baking convection fan 5, a heat dissipation A fan 6, a collecting basin 7 is arranged at the bottom of the box body 1, and the steam generating device communicates with the steam spray head, and a rotating impeller 8 is installed on the steam spray head. 8 is connected with bearing 9 outer rings.

[0021] The impeller 8 is provided with a steam channel 10, which communicates with the steam spray head 3, and a steam port 11 is provided along the side wall of the impeller 8 corresponding to the steam channel, and the steam port pushes the impeller to rotate around the steam spray head when injecting steam. The direction of the steam nozzle of the steam port 11 forms an included angle a with the vertical direction, where 0°

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com