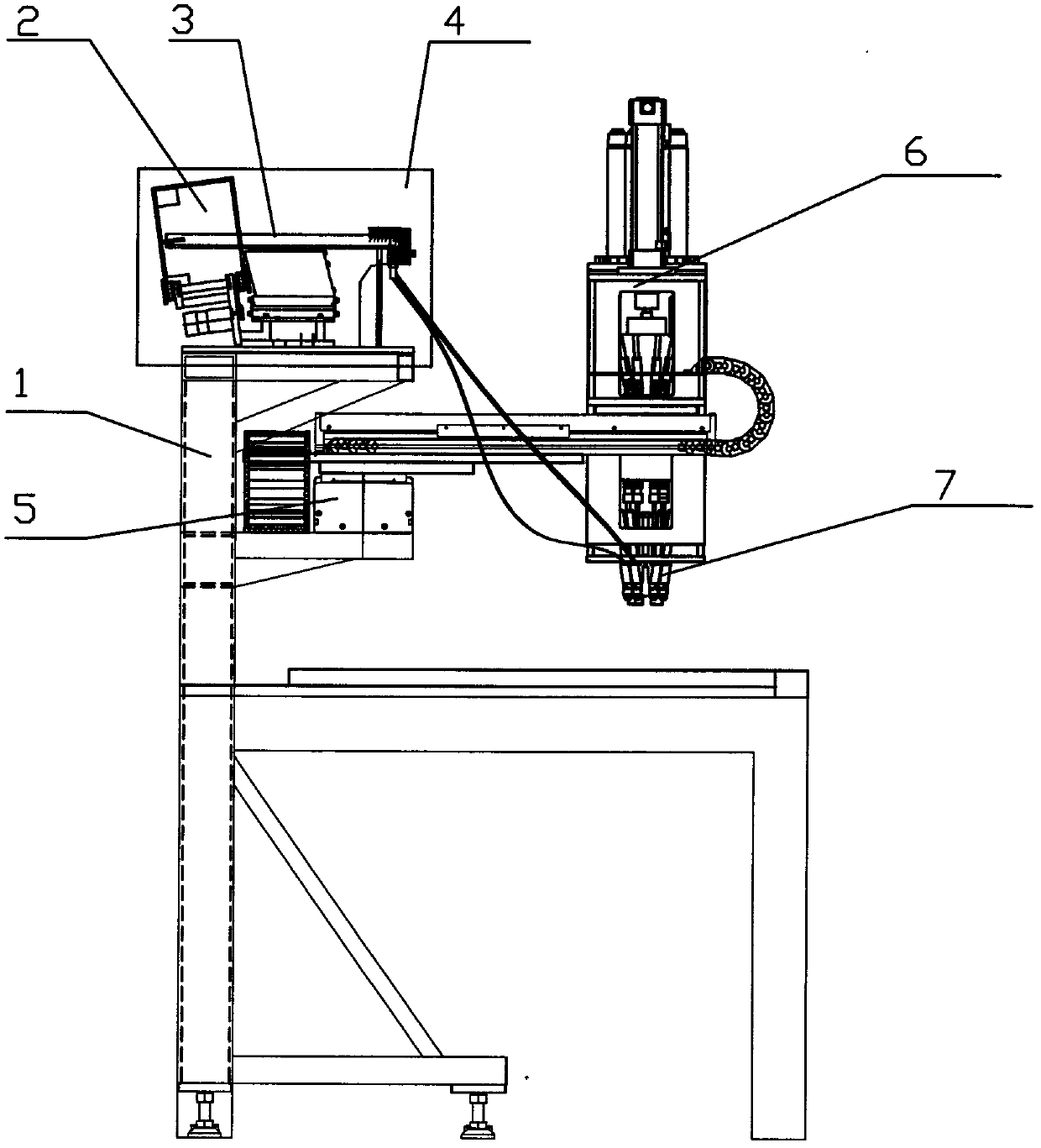

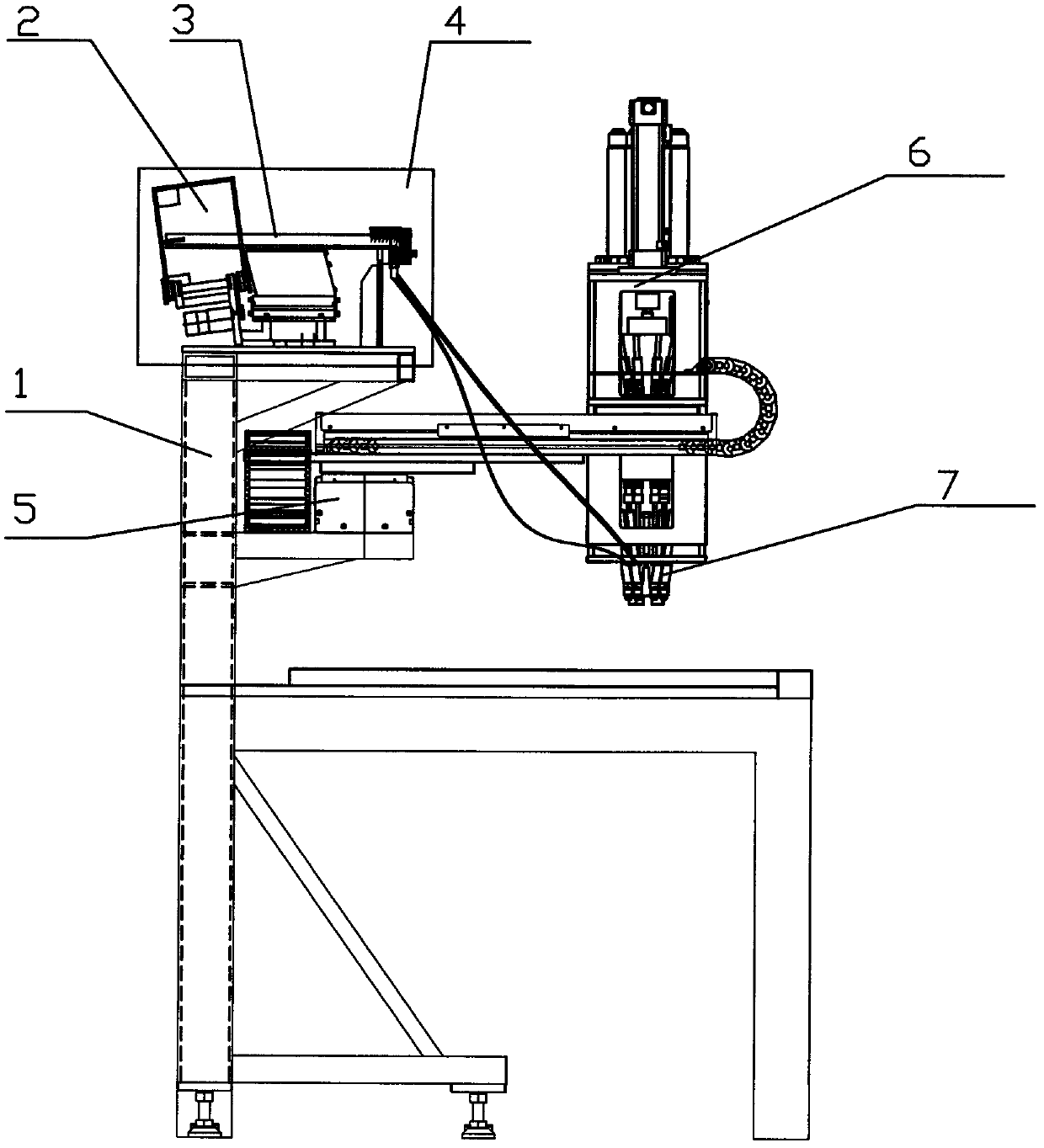

Multi-shaft blowing distribution type high-speed intelligent automatic bolt-fastening and assembling machine

A distribution type, distribution mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving quality, flexible and reliable work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The multi-axis blowing distribution type screw high-speed intelligent automatic fastening assembly machine will be described in detail below in conjunction with the embodiments.

[0014] Such as figure 1 As shown, the screw supply device 4 is installed on the frame 1, wherein the screw supply cylinder 2 is placed obliquely, the front section of the material channel 3 extends into the screw supply cylinder 2, and the other end of the material channel 3 is connected to the screw distribution mechanism. The front end of the mechanism is connected to the material pipe 8, and the rear end of the material pipe 8 is connected to the nail receiving device 7 in the screw fastening assembly mechanism 6, and a screwdriver is installed above the discharge port of the nail receiving device 7; On the shaft servo robot 5, the robot is brought to the designated mounting screw position, the screw fastening assembly mechanism 6 outputs the nail through the nail receiver 7, and the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com