Double-welding-gun automatic heat pipe welder

A technology of automatic welding machine and double welding torch, applied in welding equipment, welding accessories, welding rod characteristics and other directions, can solve the problems of low efficiency, welding efficiency needs to be further improved, poor reliability, etc., to achieve the effect of efficient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

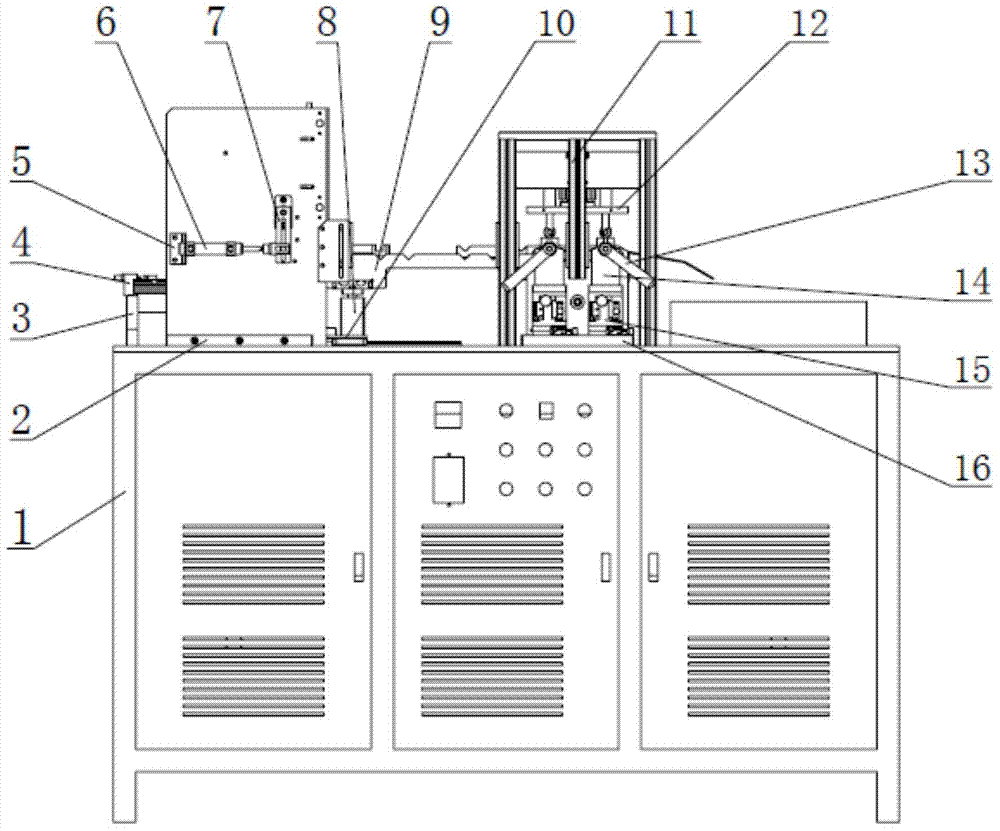

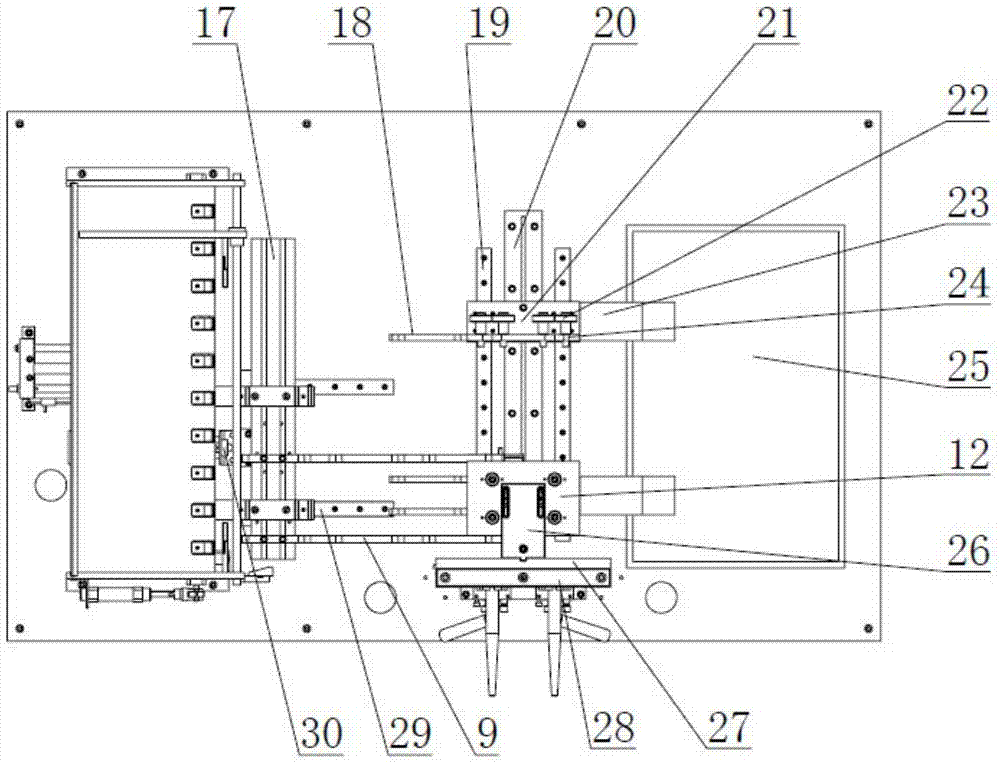

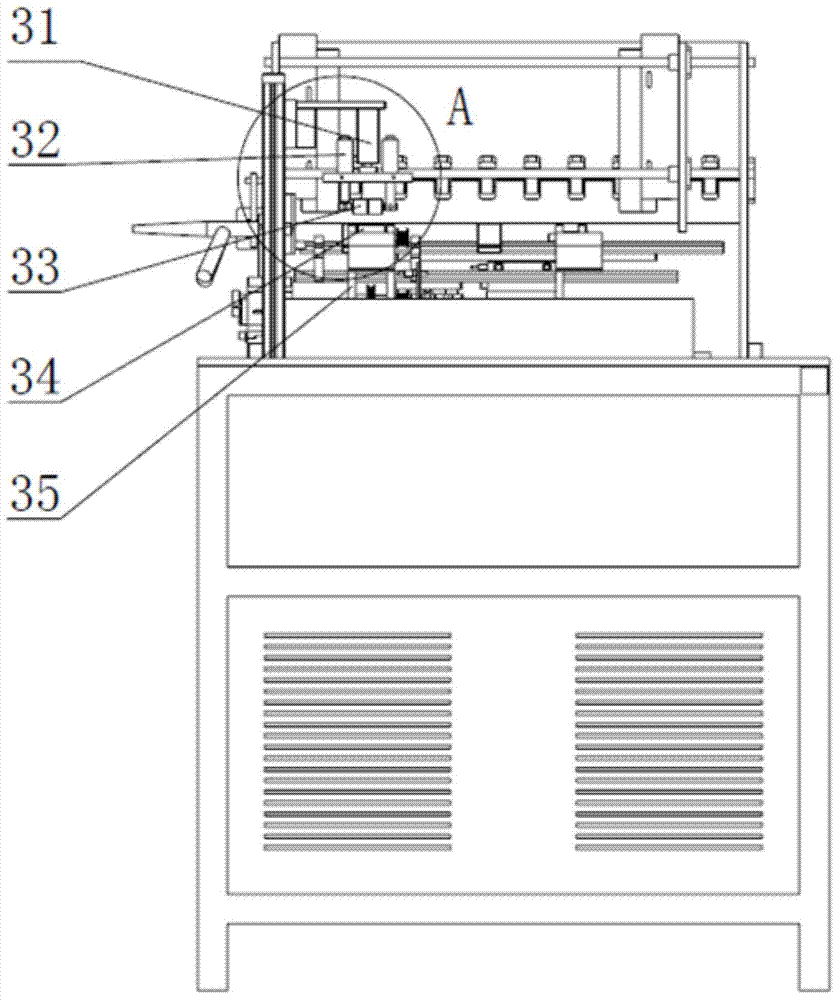

[0040] like Figure 1-7 As shown, an automatic welding machine for heat pipes with double welding torches includes a frame 1, a double pipe automatic discharge device, a double pipe automatic feed device, a double pipe automatic welding device, a double argon arc welding torch adjustment device, and a double pipe automatic blanking device and PLCs.

[0041] like figure 1 , 2 , 3, 4, and 5, the double-pipe automatic discharge device mainly includes a double-pipe automatic feeding device, an automatic shaking device and a heat pipe positioning device, wherein the double-pipe automatic feeding device is installed on the panel of the frame 1, and the material is sensed The alarm system, the automatic shaking device and the heat pipe positioning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com