Abrasion-proof rotation structure

A technology of rotating structure and rotating shaft, used in rigid shaft couplings, mechanical equipment, couplings, etc., can solve the problems of easy wear, eccentricity of the rotating shaft, easy wear, etc., to prevent "eccentricity, eliminate clearance, Avoid the effect of axial slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

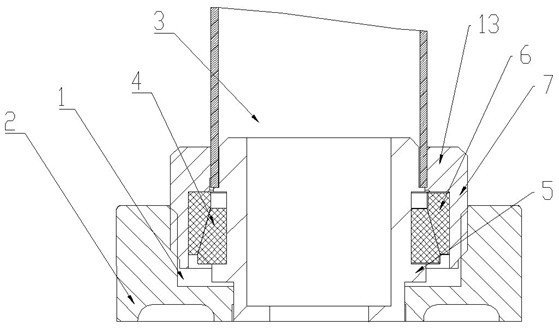

[0044] The wear-resistant rotating structure described in this embodiment is as figure 1 As shown, including: a frame 2 provided with a threaded hole 1;

[0045] A rotating shaft 3, the rotating shaft 3 is arranged in the base 2;

[0046] The rotating structure is also provided with:

[0047] an elastic inner gasket 4, the elastic inner gasket 4 is nested on the rotating shaft 3;

[0048] The limit device 5 is arranged around the rotating shaft 3 and conflicts with the bottom end of the elastic inner gasket 4;

[0049] The rotating structure also includes a pressing cover 7, the pressing cover 7 is provided with threads suitable for screwing into the threaded hole 1, and the bottom end of the pressing cover 7 and the bottom end of the threaded hole 1 have a A gap suitable for screwing in the compression cover 7;

[0050] An elastic outer gasket 6 is arranged between the pressing cover 7 and the elastic inner gasket 4, and the elastic outer gasket 6 is press-fitted with the...

Embodiment 2

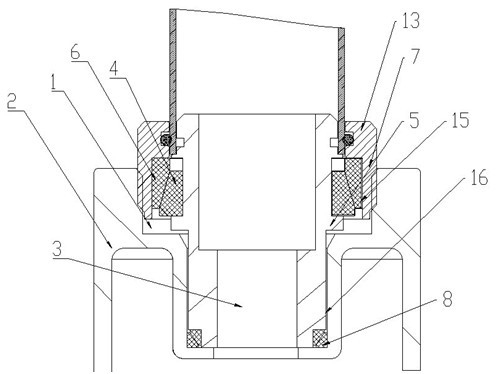

[0056] The wear-resistant rotating structure described in this embodiment is as figure 2 As shown, including: a frame 2 provided with a threaded hole 1;

[0057] A rotating shaft 3, the rotating shaft 3 is arranged in the base 2;

[0058] The rotating structure is also provided with: an elastic inner gasket 4, the elastic inner gasket 4 is nested on the rotating shaft 3;

[0059] The limit device 5 is arranged around the rotating shaft 3 and conflicts with the bottom end of the elastic inner gasket 4;

[0060] The rotating structure also includes a pressing cover 7, the pressing cover 7 is provided with threads suitable for screwing into the threaded hole 1, and the bottom end of the pressing cover 7 and the bottom end of the threaded hole 1 have a A gap suitable for screwing in the compression cover 7;

[0061] An elastic outer gasket 6 is arranged between the pressing cover 7 and the elastic inner gasket 4 , and the inner side of the pressing cover has a groove 15 for ac...

Embodiment 3

[0068] The wear-resistant rotating structure in this embodiment is as Figure 4 As shown, the difference from Embodiment 2 is that in this embodiment, the angle between the contact surface of the elastic inner gasket and the elastic outer gasket and the horizontal plane is 65°.

[0069] In this embodiment, a protective cover 14 is provided around the clamping end 13, and the protective cover 14 is threadedly connected to the clamping end 13, and the lower surface of the protective cover 14 is set in conflict with the base 2; In the rotating structure described in the embodiment, two sealing grooves 11 are formed on the rotating shaft 3 in the shaft mounting hole 16 , and O-rings 12 are arranged in the sealing grooves 11 .

[0070] In addition, in this embodiment, the elastic inner gasket and the elastic outer gasket are non-closed sleeves, and the gap between the gaps of the non-closed sleeves is 0.5mm. As an optional implementation, the The gap at the notch can also be optio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com