Outer wall hole forming process for PVC pipe machining

A PVC pipe and process technology is applied in the field of outer wall opening technology for PVC pipe processing, which can solve the problems of inability to fix the PVC pipe, low processing efficiency, inconsistent hole spacing, etc., so as to reduce labor intensity, improve work efficiency, and hole spacing. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

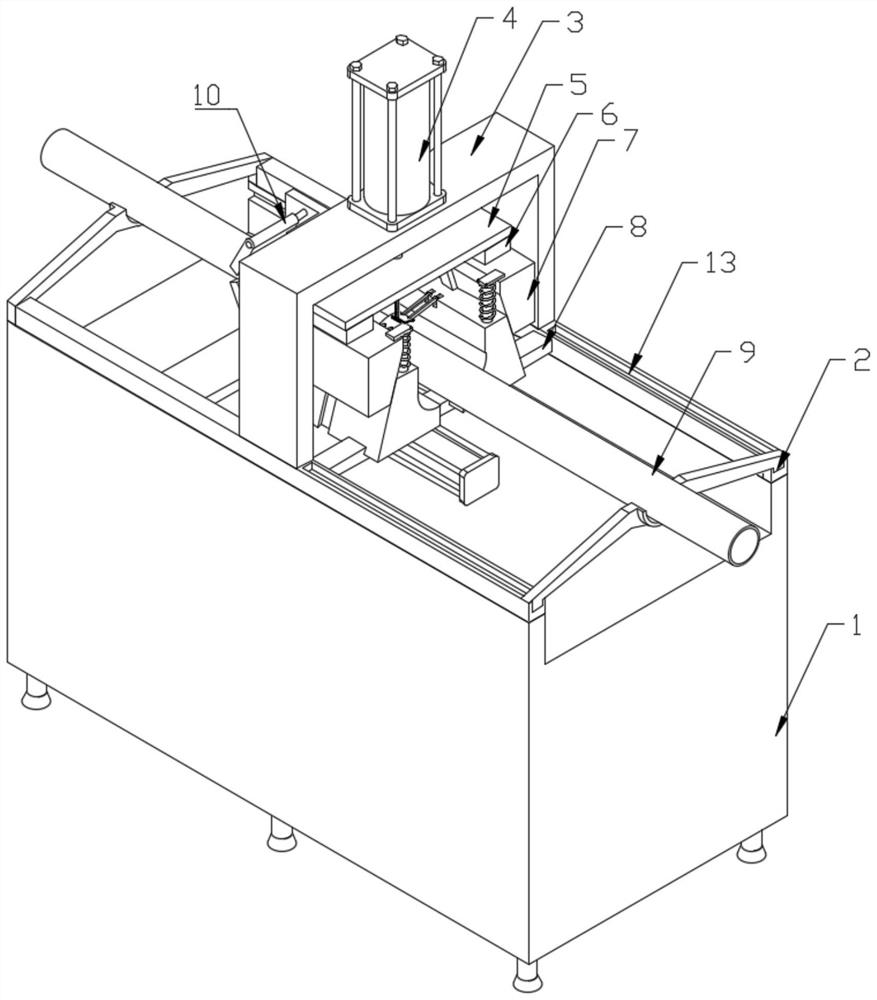

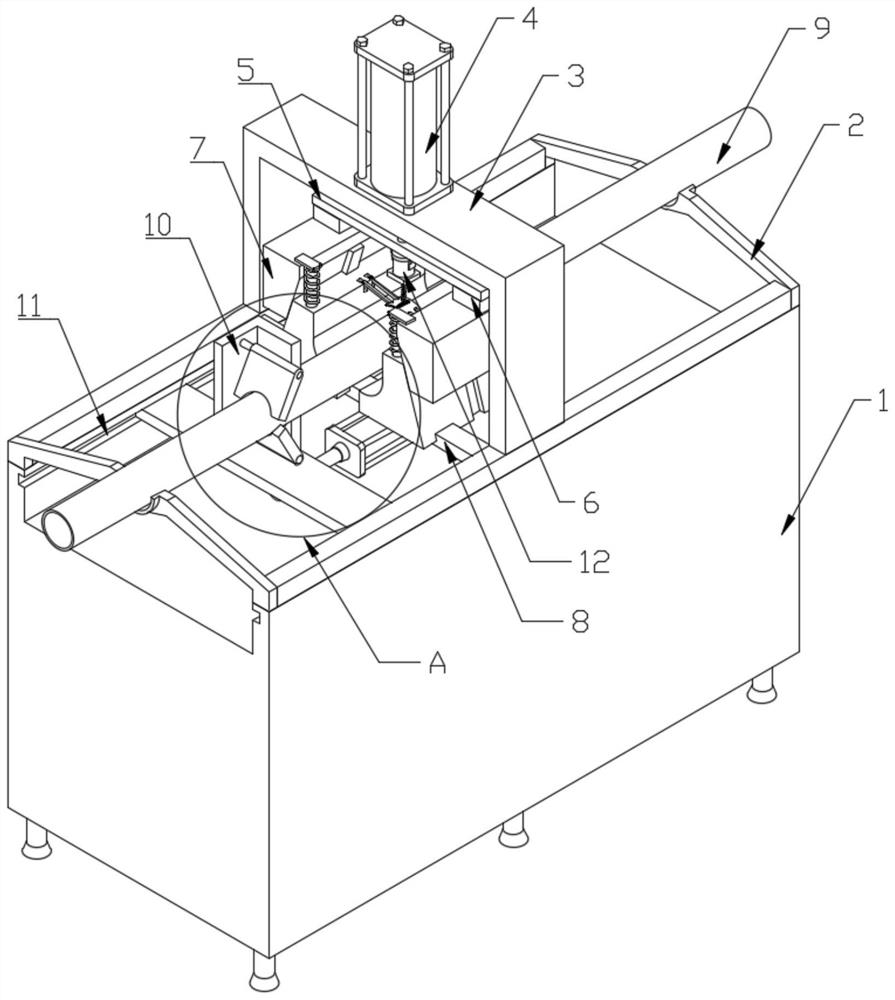

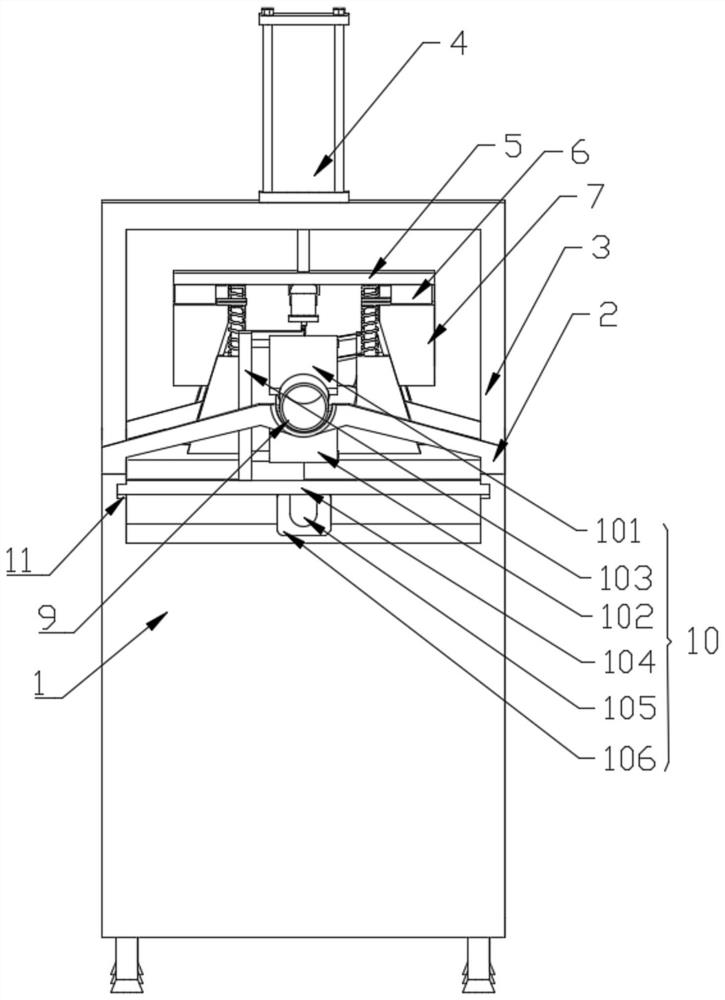

[0042] Attached below figure 1 To attach Figure 7 The present invention is further described with embodiment:

[0043] A process for perforating an outer wall for PVC pipe processing, the method comprising the steps of:

[0044] A. PVC pipe threading and placement, first fix the PVC pipe on the PVC pipe processing equipment, when placing the PVC pipe, first pass one end of the PVC pipe through the PVC pipe clamping assembly and the PVC pipe displacement assembly, Then place the two ends of the PVC pipe on the PVC pipe bracket;

[0045] B. Automatic clamping and punching of the PVC pipe. After the PVC pipe is placed, the lifting cylinder drives the horizontal plate to move downward. The elastic block first contacts the PVC pipe clamping component. Under the pressure of the elastic block, the PVC tube clamping component Clamp the PVC pipe, and then the drilling motor drives the drill to rotate to open the PVC pipe;

[0046] C. Automatic cleaning of drill debris. After the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com