Full-automatic effective drilling machine for furniture panel

A fully automatic, plate-based technology, applied to fixed drilling machines, etc., can solve problems such as low production efficiency, high labor intensity, and non-continuous production, and achieve the effects of simple structure, reduced labor intensity, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

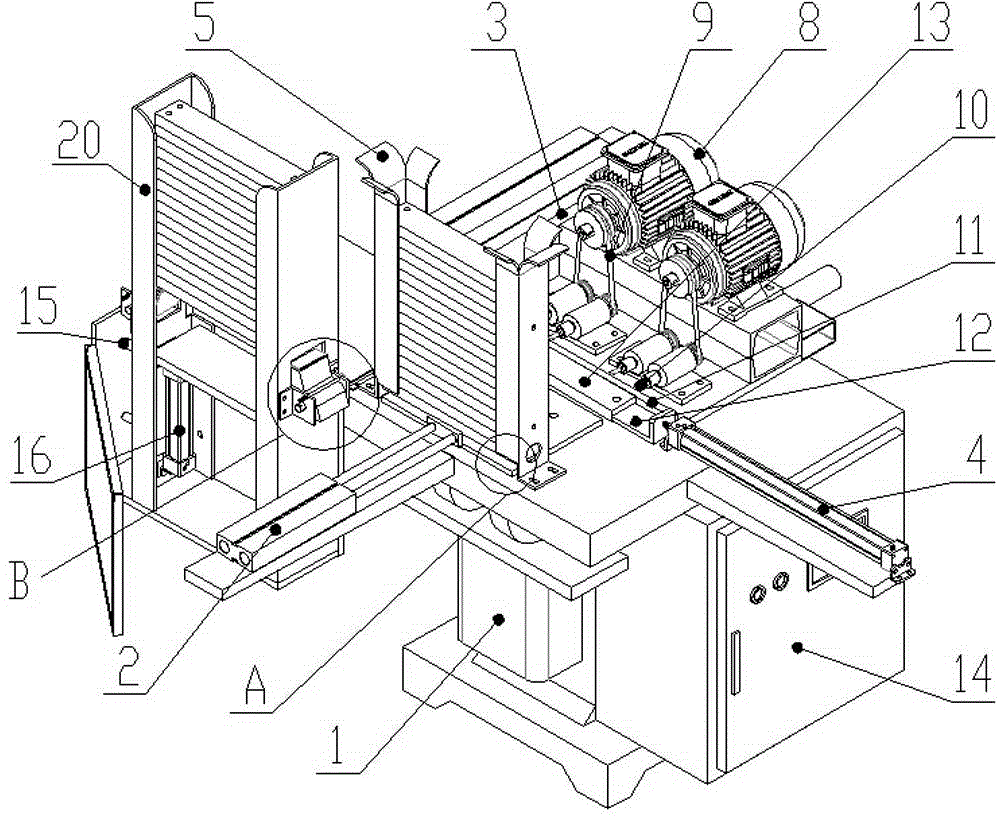

[0051] The fully automatic and high-efficiency hole-leading machine for furniture panels in this embodiment includes a main frame. The push cylinder of the workpiece, the main frame behind the feeding bin is equipped with a drilling device for side drilling of the workpiece, and the main frame on the side of the feeding bin is equipped with a machining center for pushing out the processed workpiece. The horizontal push cylinder of the workpiece; the main frame on the other side of the feed bin is provided with a storage device for recovering and processing workpieces, and the horizontal push cylinder and the storage device are respectively located on both sides of the feed bin.

Embodiment 2

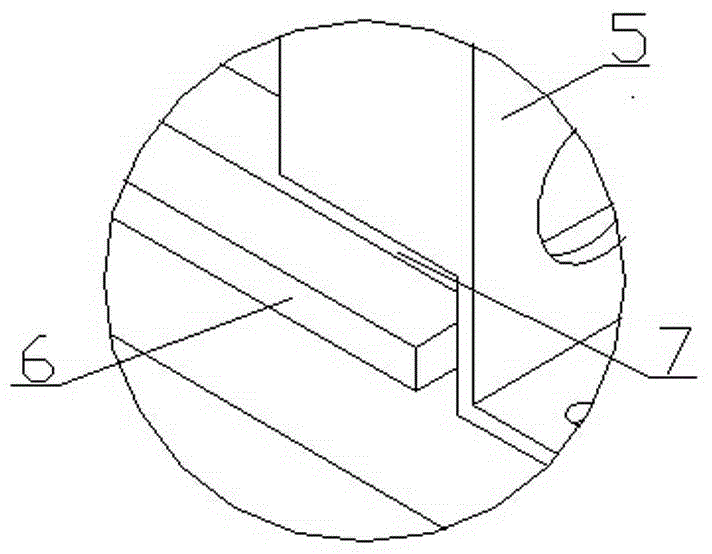

[0053] The fully automatic and high-efficiency hole-leading machine for furniture panels in this embodiment includes a main frame. The push cylinder of the workpiece, the main frame behind the feeding bin is equipped with a drilling device for side drilling of the workpiece, and the main frame on the side of the feeding bin is equipped with a machining center for pushing out the processed workpiece. The horizontal push cylinder of the workpiece; the main frame on the other side of the feed bin is provided with a storage device for recycling and processing workpieces, and the horizontal push cylinder and the storage device are respectively located on both sides of the feed bin; the feed The bin includes two slotted plates arranged on the main frame, and the openings of the two slotted plates are arranged correspondingly to form a feeding bin for placing workpieces to be processed.

Embodiment 3

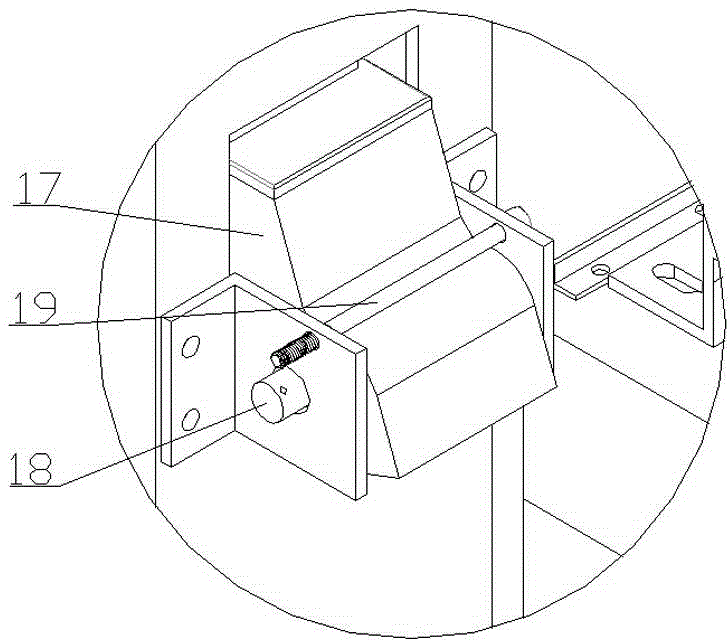

[0055] The fully automatic and high-efficiency hole-leading machine for furniture panels in this embodiment includes a main frame. The push cylinder of the workpiece, the main frame behind the feeding bin is equipped with a drilling device for side drilling of the workpiece, and the main frame on the side of the feeding bin is equipped with a machining center for pushing out the processed workpiece. The horizontal push cylinder of the workpiece; the main frame on the other side of the feed bin is provided with a storage device for recycling and processing workpieces, and the horizontal push cylinder and the storage device are respectively located on both sides of the feed bin; the feed The warehouse includes two slotted plates arranged on the main frame, the openings of the two slotted plates are arranged correspondingly to form a feeding bin for placing workpieces to be processed; the pushing cylinder is connected with a pushing plate, and the slotted plates There is an openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com