New energy vehicle battery pack assembly and new energy vehicle

A technology for new energy vehicles and battery packs, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as insufficient structural strength and rigidity, complex structure of battery pack devices, etc., and meet installation reliability requirements, strength and stiffness performance Good, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

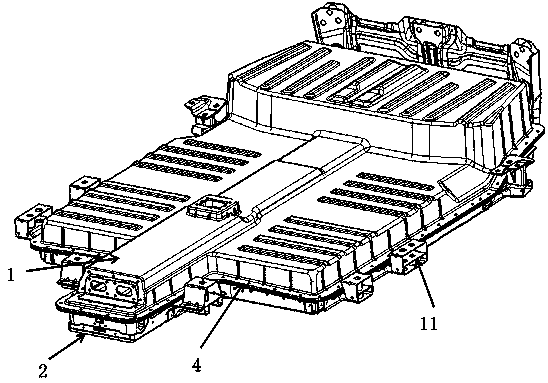

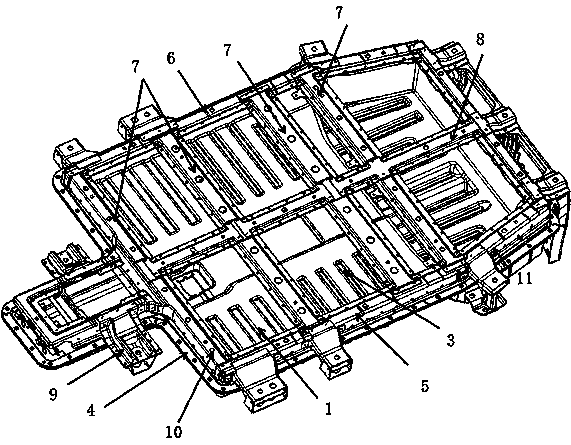

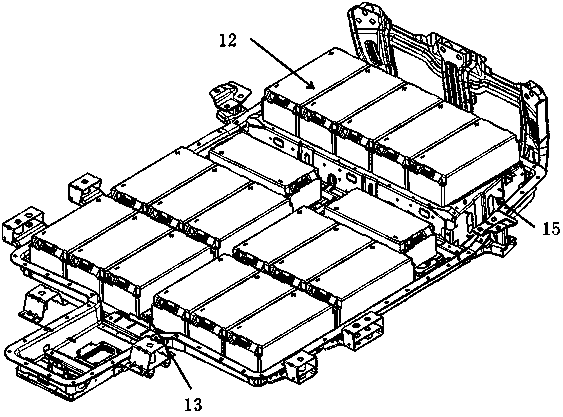

[0027] Figure 1 to Figure 3 It shows a battery pack assembly for a new energy vehicle. The main structure of the battery pack assembly is divided into an upper case 1, a lower case 2, and a battery module 12; the overall shape of the upper case 1 and the lower case 2 presents a T-shape The shape fits the lower structure of the car body and maximizes the use of the space under the car body; the upper shell 1 and the lower shell 2 are fixedly connected by bolts, which can be easily installed and disassembled; and the upper shell 1 and the lower shell 2 The inner sides are respectively provided with mutually symmetrical frame structures, so that the battery modules 12 can be fixedly arranged in the frame structures on the inner sides of the upper case 1 and the lower case 2. The present invention fixes the battery modules in the frame structures, Not only can the fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com